Vibration piling hammer

A technology of piling hammer and vibration exciter, which can be applied to sheet pile walls, buildings, infrastructure engineering, etc., and can solve problems such as large energy waste, slow construction speed, and large vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

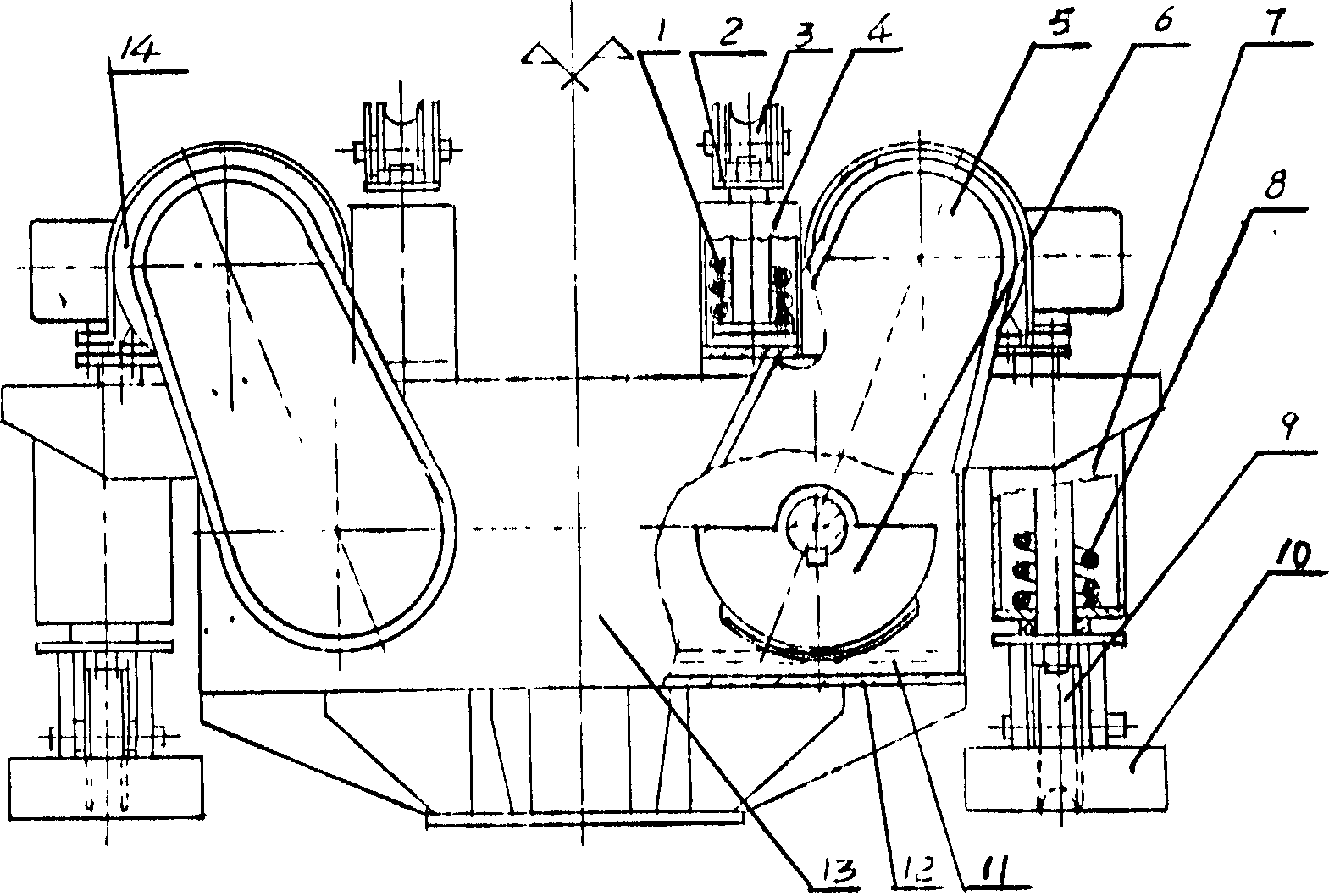

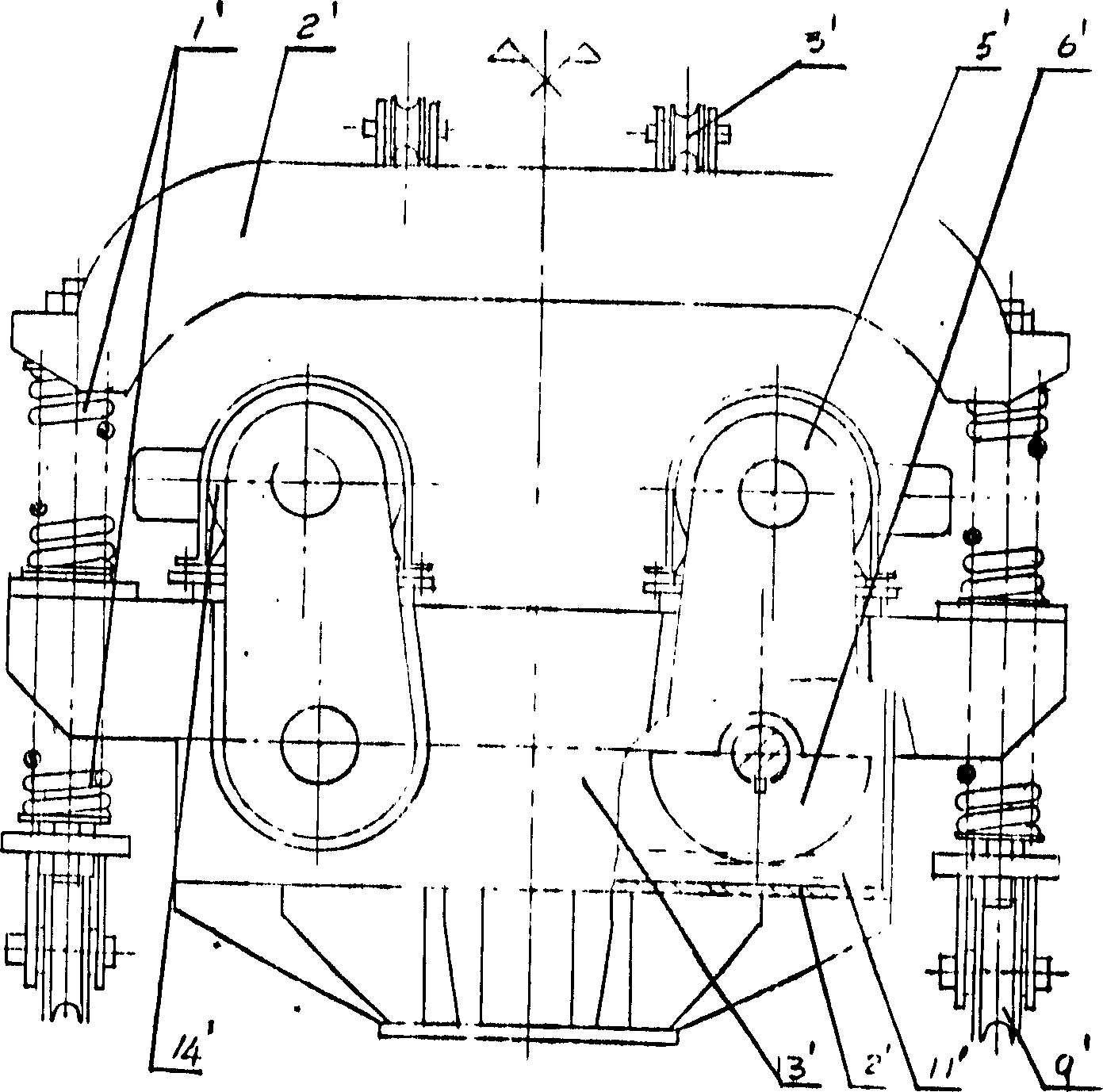

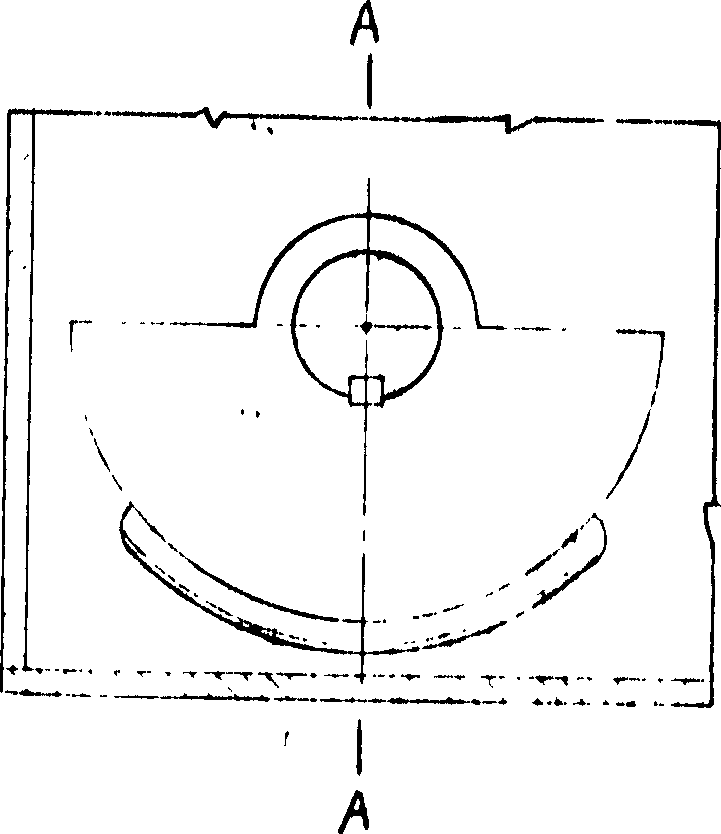

[0015] Accompanying drawing has shown the structure of the present invention and its embodiment, describe each relevant detail of its embodiment in detail again below in conjunction with accompanying drawing, this vibrating piling hammer includes motor 14, belt drive system, extracting pile and pressurization damping system , the eccentric body 6 and the vibrator 13 are respectively designed to work independently on the vibratory hammer, including closed spring boxes 4, 7, damping springs 1, 8, damping counterweights 10, beams 2, hanging The pile extraction vibration reduction and pressurization vibration reduction system of wheel 3 and pulley 9 (see attached figure 1 ), according to the amplitude-frequency characteristics of the dynamic compliance of the forced vibration

[0016] Sexual equation: W 0 = 1 / k ( 1 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com