Motor frequency change servo controlling system

A technology of servo control system and motor, applied in the field of frequency conversion servo control system, can solve the problems of unusable, high cost, speed-up limit of rotor centrifugal effect, etc., achieve simple manufacturing process, low manufacturing cost, and improve various performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

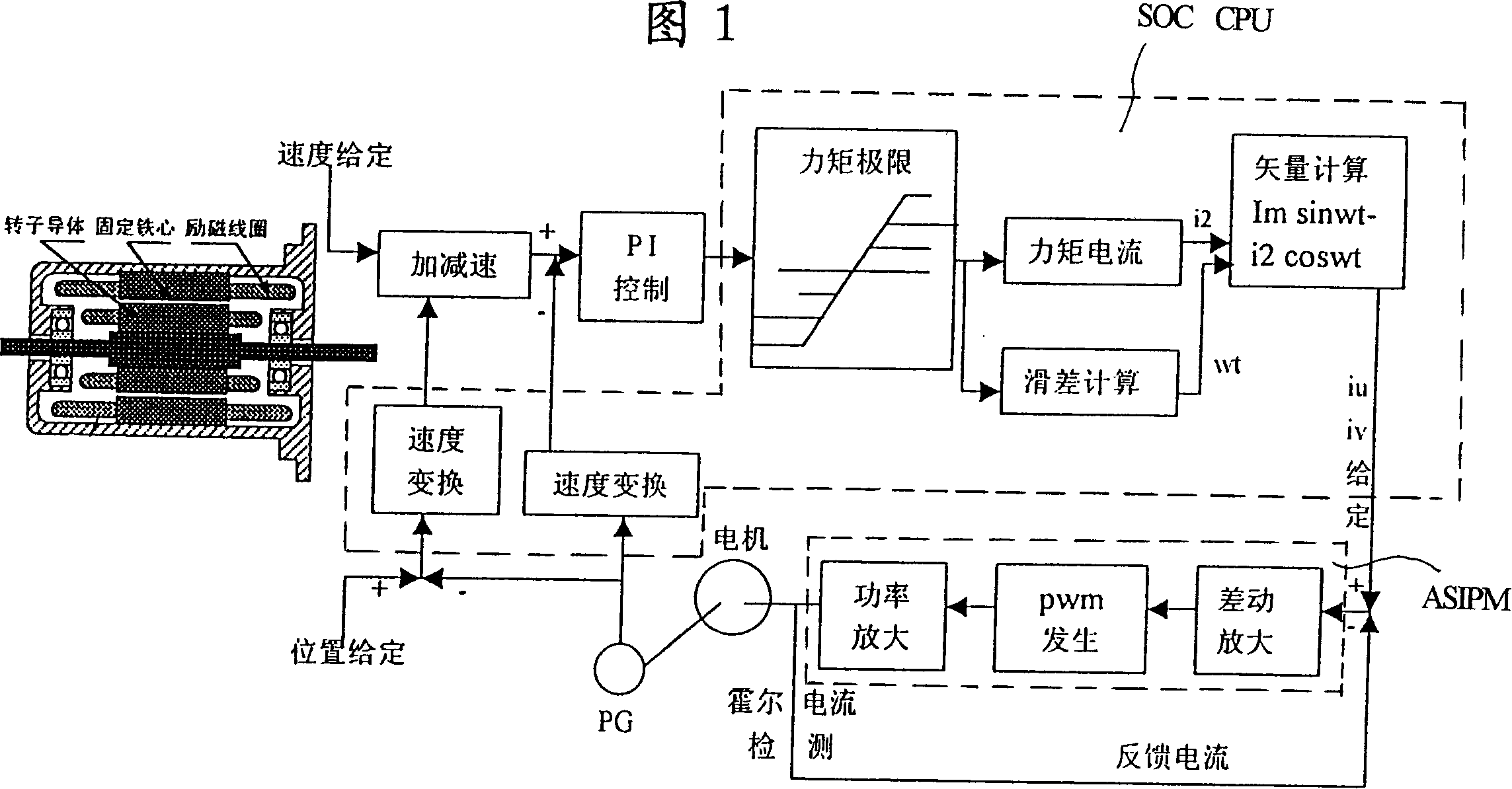

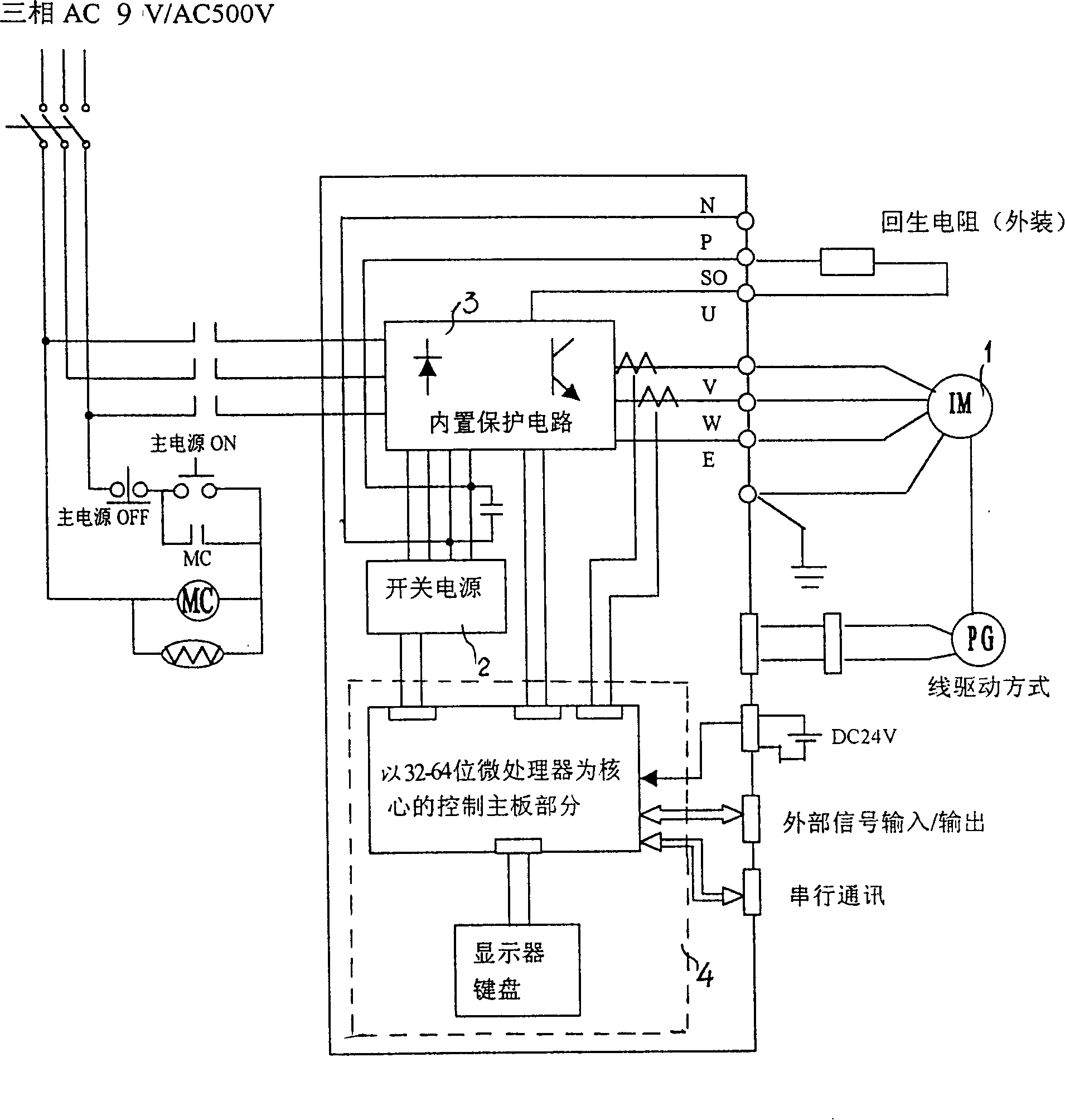

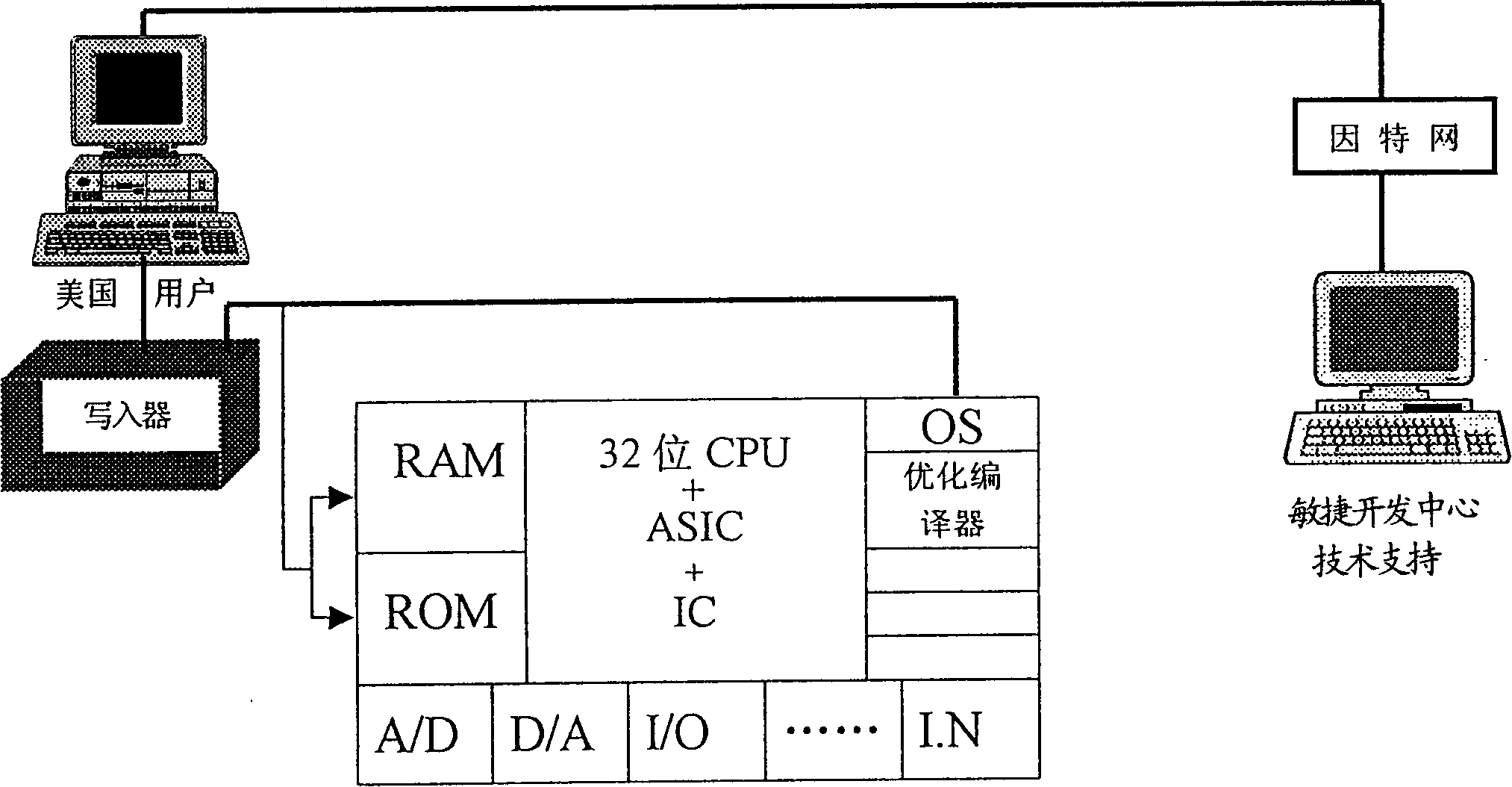

[0013] Fig. 1 is a schematic diagram illustrating the control principle of the control system of the present invention. The three-phase AC asynchronous motor is a rotating magnetic field generated by the current flowing through the stator coil to make the rotor rotate. The induced current of the rotor is proportional to the speed difference between the speed of the rotating magnetic field and the rotor (called slip or slip). In order to ensure that the rotating magnetic field and the induced current maintain an orthogonal relationship, AC vector control is required. Therefore, compared with DC servo motors and AC synchronous servo motors, its control is much more difficult. The invention integrates an AC vector control unit into an SOC CPU through microelectronic technology and semiconductor power module technology, and integrates a three-phase AC asynchronous motor control power supply into an ASIPM or SIMP. The principle is to input the required control mode to the SOC CPU ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com