Prefabricated concrete shear wall building structure and its construction method

A prefabricated concrete and building structure technology, applied in the direction of building structure, construction, etc., can solve problems such as poor structural integrity, restrictions on the popularization and use of prefabricated shear wall systems, and complex joint joints to achieve enhanced integrity, reliable connections, Improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

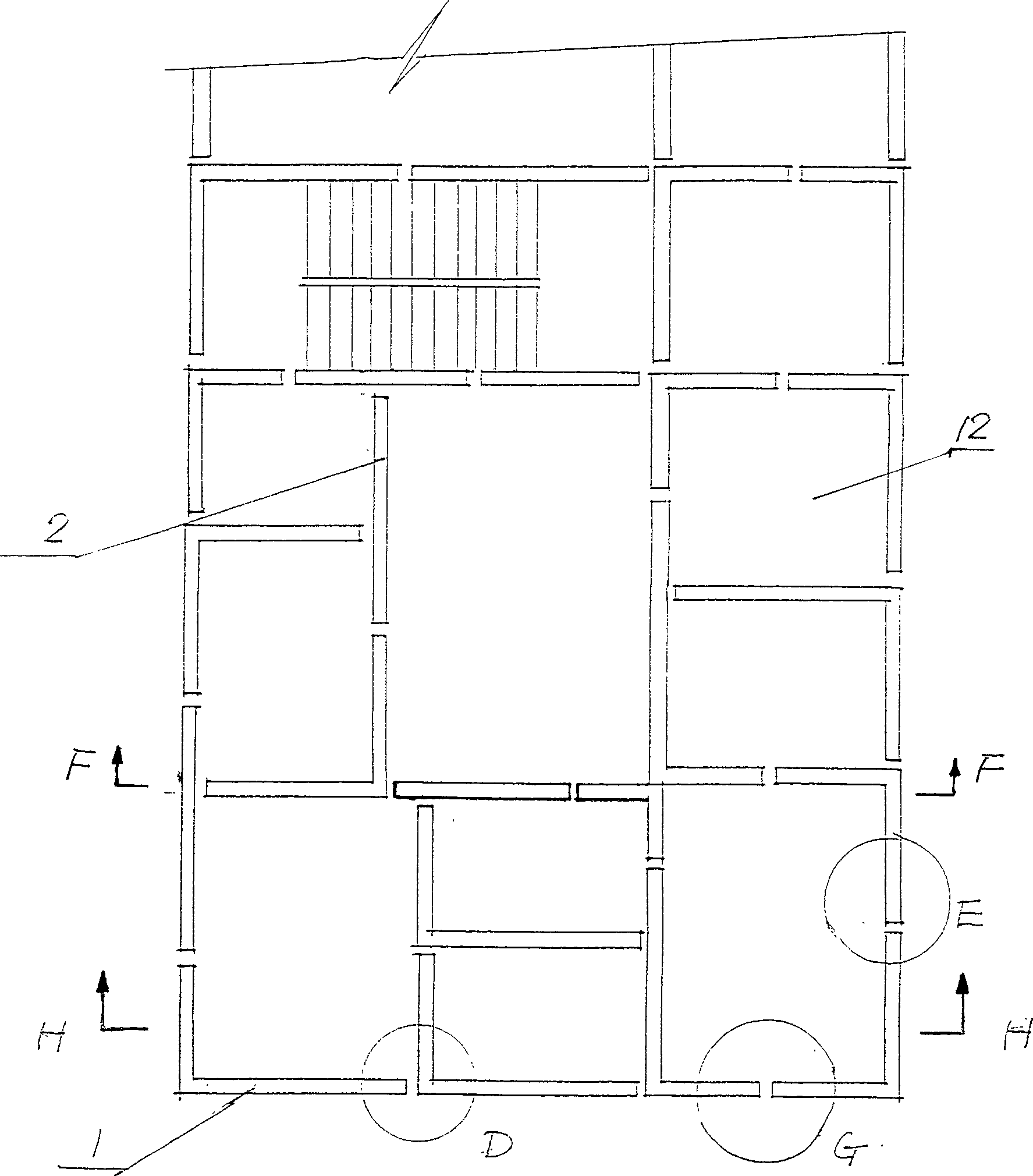

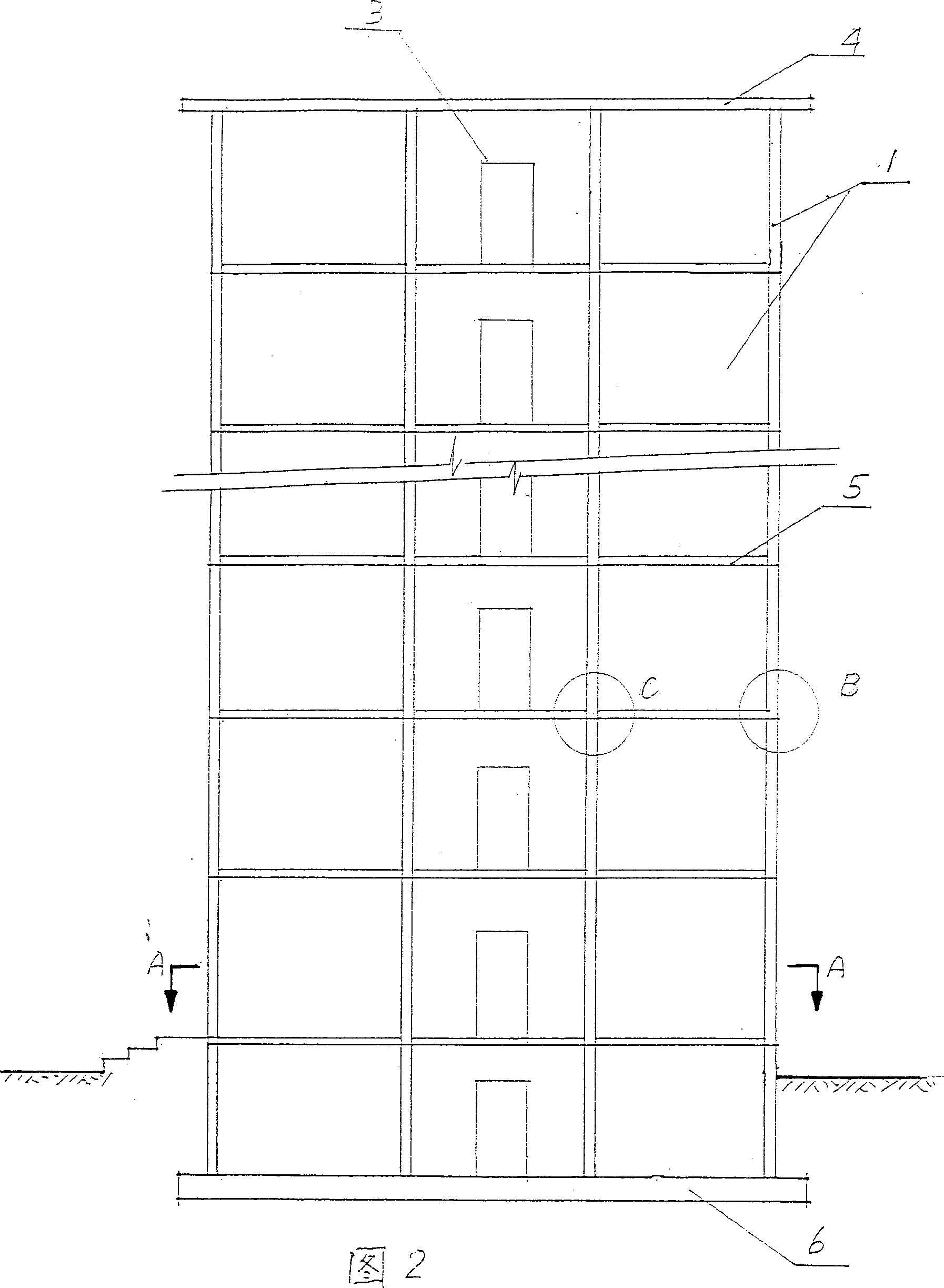

[0028] The meanings represented by the numbers drawn in the attached drawings: 1 right-angle plate 2 flat plate 3 door opening 4 roof 5 integrally poured concrete laminated plate 6 concrete foundation 7 steel wire mesh sheet 8 obliquely inserted steel wire 9 polystyrene foam board 10 foam glass strip 11 Prestressed concrete thin slab 12 integrally poured concrete lamination layer 13 wall panel tooth-shaped notch 14 steel wire network 15 prestressed steel bar 16 C-shaped steel 17 die net 18 connection positioning block 19 plug-in steel 20 final expansion section of die net 21 solid Wallboard 22 wire through pipe 23H-shaped steel 24 connection weld 25 connection steel plate 26 connection steel bar 27 plug-in steel bar

[0029] The first embodiment is for a certain 400,000 m 2 The technical scheme of the residential area, including public buildings and auxiliary buildings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com