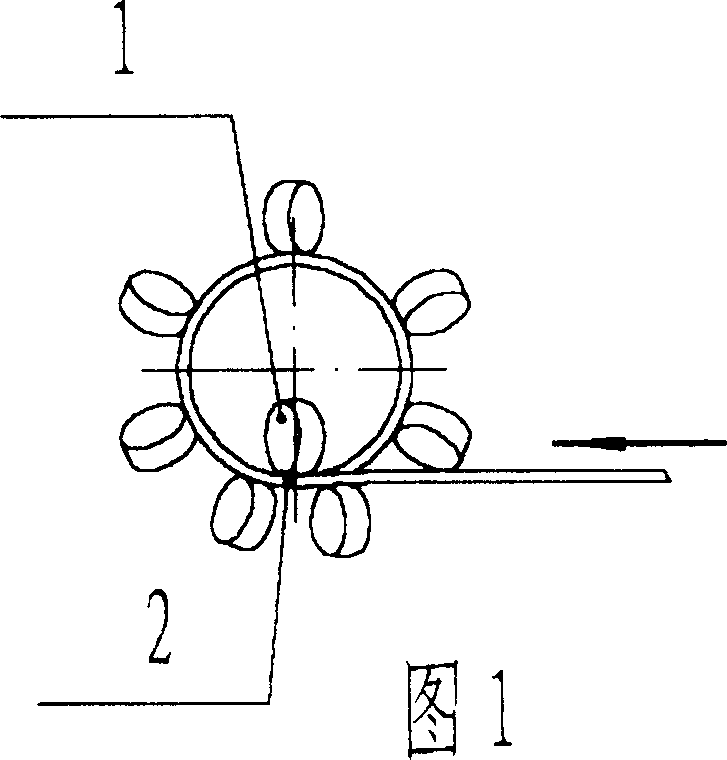

Inner press roller roll type outline matching screw tube blank

A contour line and matching technology, applied in the field of internal pressure rollers, can solve problems such as the lack of wavy bending indentations of tube billets, unreasonable internal pressure roller roll shape, unreasonable roll shape design, etc., to achieve uniform deformation and improve internal quality , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

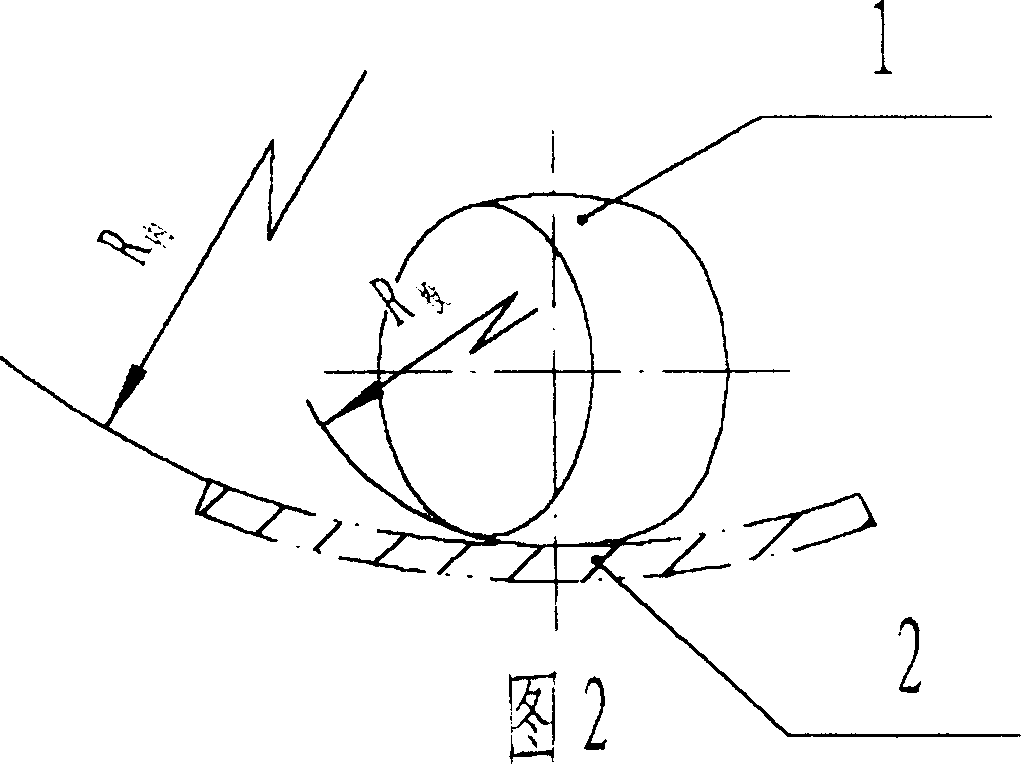

[0020] The roll shape curve of the inner pressure roller 1 can be determined by the radius of the roll shape curve of the inner pressure roller, that is:

[0021] R 母 =(R 投 -R 半 ×Sin 2 alpha 内 ) / cos 2 alpha 内 , according to the process parameters of spiral welded pipe products, as the known conditions of this embodiment.

[0022] The inner radius R of the spiral tube blank 2 is known 内 =400mm, inner forming angle α 内 = 60 degrees, the radius R of the inner pressure roller 1 半 =75mm, since the manufactured internal pressure roller 1 is in line contact with the spiral tube blank 2, then R 投 = R 内 =400mm, according to this we can know:

[0023] R 母 =(400-75×Sin 2 60) / cos 2 60=1375(mm)

Embodiment 2

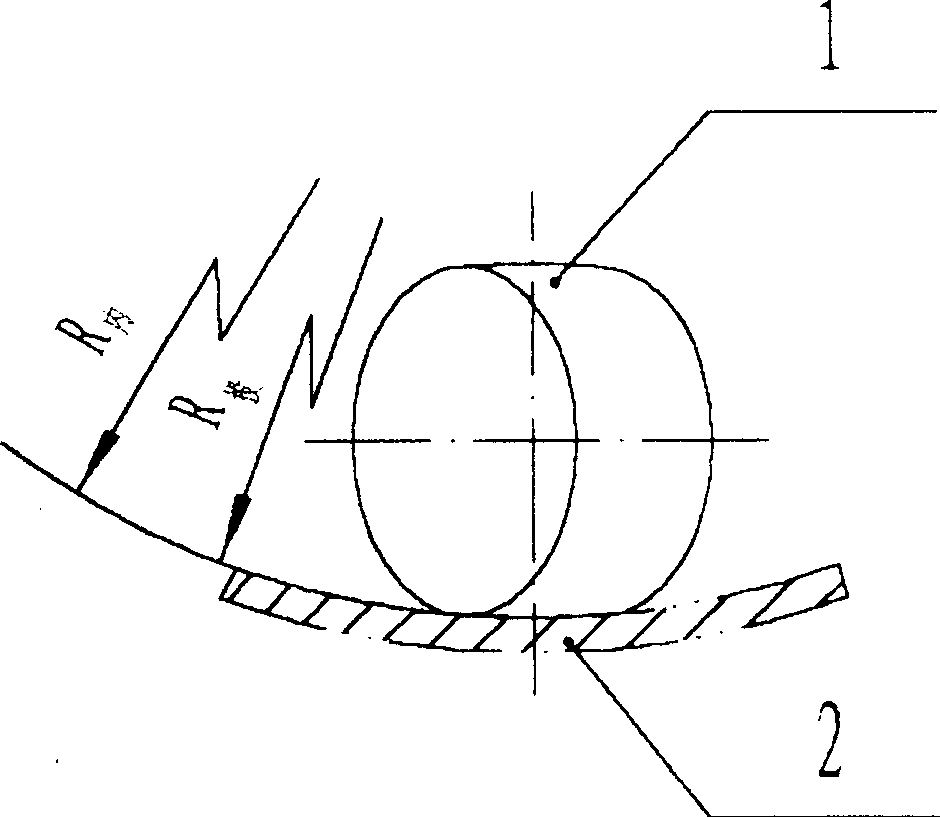

[0025] The second embodiment is to verify the applicability of the known roll shape when the roll shape curve of the internal pressure roll 1 is determined.

[0026] The radius R of the roll shape curve of the inner pressure roll is known 母 is 200mm, the installation angle is 40 degrees, and the diameter is 150mm. Order R 内 = R 投 achieve line contact, the R 内 can be obtained by the equation R 内 = R 半 ×Sin 2 alpha 内 +R mother×cos 2 alpha 内 ,inferred:

[0027] R 内 =75×Sin 2 40+200×cos 2 40 = 148 (mm).

[0028] It can be seen that, when the radius of the roll curve of the inner pressure roller is 200 mm, the radius of the spiral tube blank 2 determined by the line contact is 148 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com