Shrinkproof, wrinkle-proof, non-deforming cotton knitted shell-fabric dyeing and finishing process

A technology of cotton knitting and craftsmanship, applied in the direction of fabric surface trimming, textile and paper making, heating/cooling fabrics, etc., can solve the problems that are not easy to prevent, and achieve the effect of low cost, strong operability and simple operation process

Inactive Publication Date: 2003-03-26

YONGFENG TEXTILE SHAGHAI

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Easing shrinkage can be slightly removed through relaxation treatment during fabric processing, or continuous compression finishing in the final process, but it is not easy to prevent shrinkage caused by yarn bulking because it is the nature of cellulose fibers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0015] According to the data analysis of the above two tables:

[0016] The shrink-proof, wrinkle-resistant, non-deformation cotton knitted fabric produced by the invention is superior to similar foreign products, and the product quality reaches an advanced level, and has won the favor of some international well-known brand clothing manufacturers. The cotton knitted fabric prepared by the invention is adopted.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

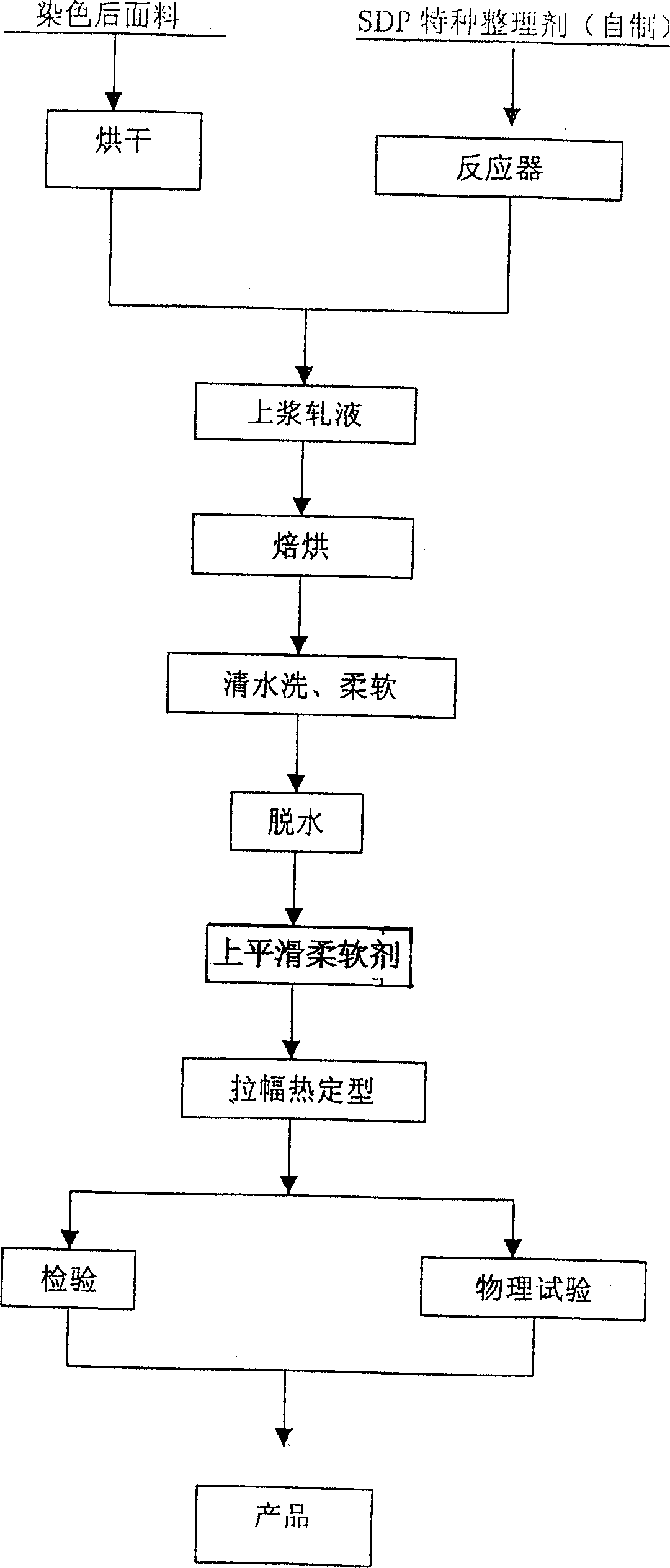

The invention is a dyeing technique of shrink-proof, wrinkle-proof and un-deformable cotton knitted plus material. It includes: after dyeing, dry grey cloth, add prescribed rinsing and homemade special arranging agent (SDP) to the reactor and then constantly stir them and adjust pH value and after complete reaction, being sizing and pressing liquid, and then carry through cross-linking, baking, washing, softening, dehydration, smearing smoothing agent, stentering shaping, verifying and packing. Its character: the baking technique: the temperature 150-180 degree C, the time 2-3 minutes and baking tech8nique is continually carried through in the hot-shaping stenter; the length of shaping machine is 24m and it has 8 box regions, 1-3 baking region and 4-7 shaping region whose technical time is 40s.

Description

1. Technical Field: [0001] The invention relates to a dyeing and finishing process for fabrics, in particular to a dyeing and finishing process for shrink-resistant, wrinkle-resistant, and non-deformation cotton knitted fabrics, which is applied to the production of shrink-resistant, wrinkle-resistant, and non-deformation cotton knitted fabrics, and provides users with stable quality , High-quality famous and high-quality clothing fabrics. 2. Background technology: [0002] Because cellulose fiber has excellent water absorption, moisture absorption, moderate strength, and easy dyeability, it has been the main material for underwear and shirts since ancient times, especially natural fibers such as cotton and linen. People have to tolerate some creases and shrinkage. However, the regenerated cellulose fiber that appeared in the early 20th century, because of its low wetting strength and the shrinkage and wrinkle during washing exceeded the allowable limit, so efforts began to use c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06C7/02D06M13/12

Inventor 曹永庆郭新华

Owner YONGFENG TEXTILE SHAGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com