Complex material distributing method in wall and floor tile production

A technology for wall and floor tiles and fabrics, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of surface layer wear and affect the effect of durable use, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

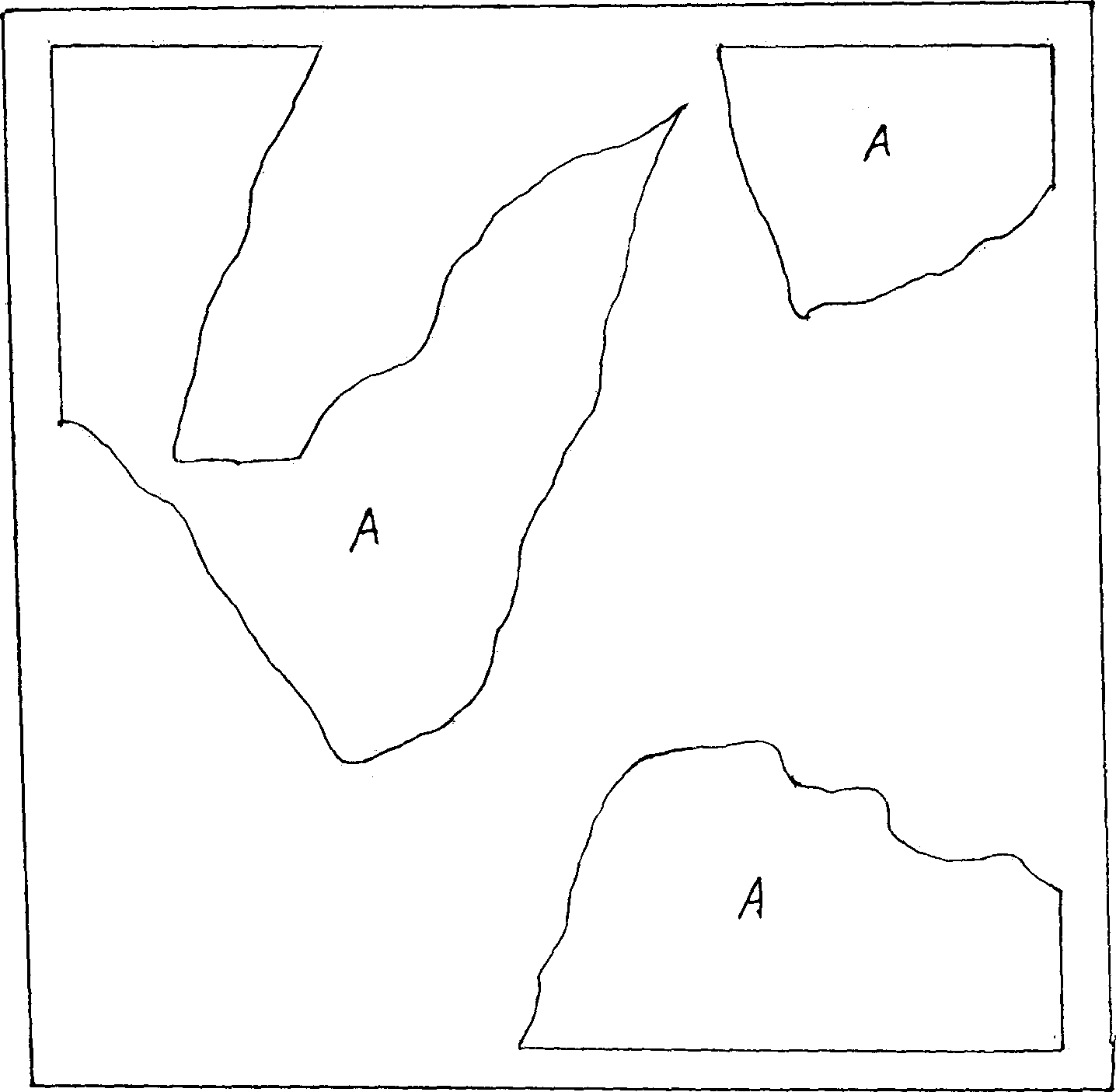

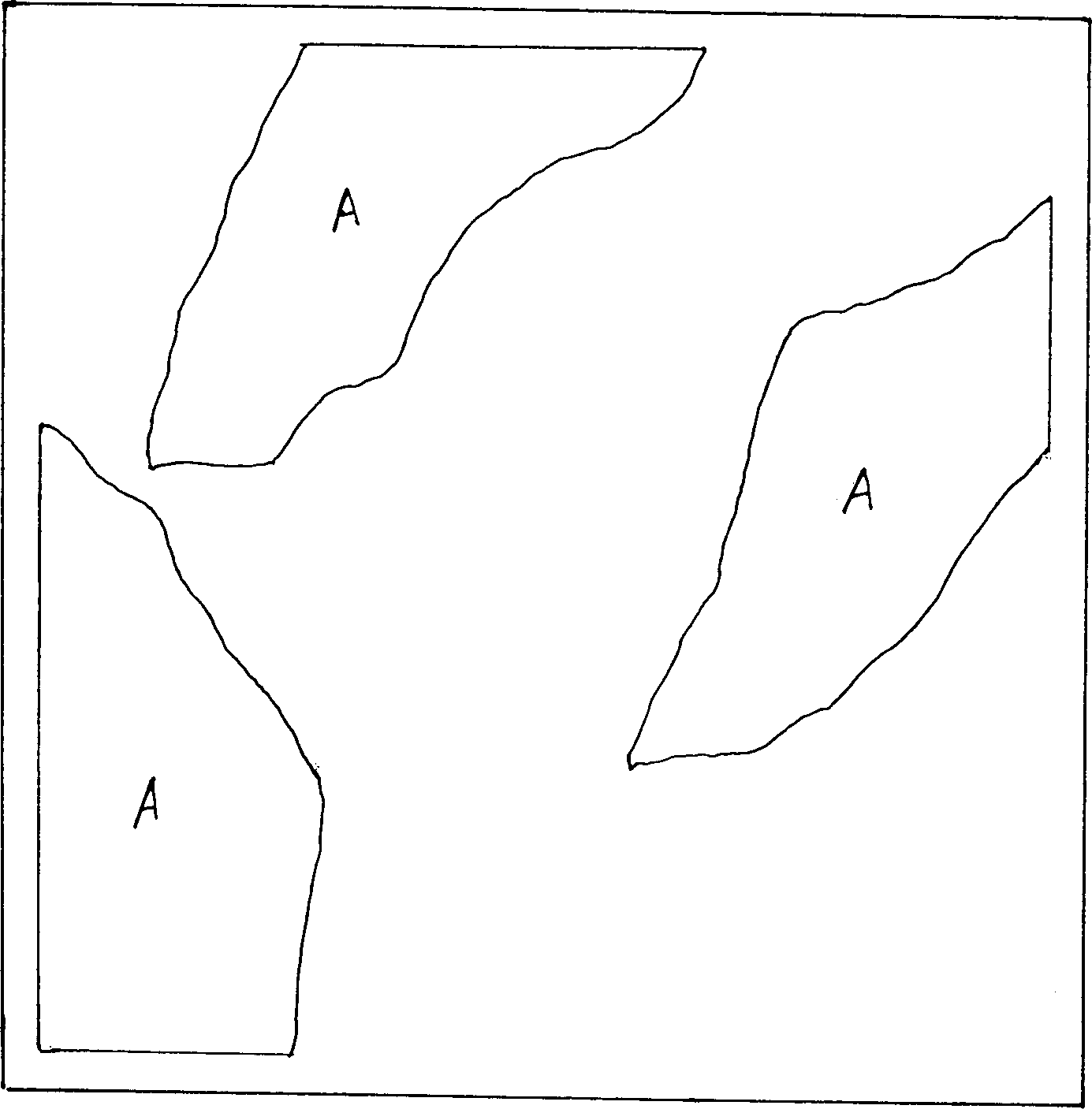

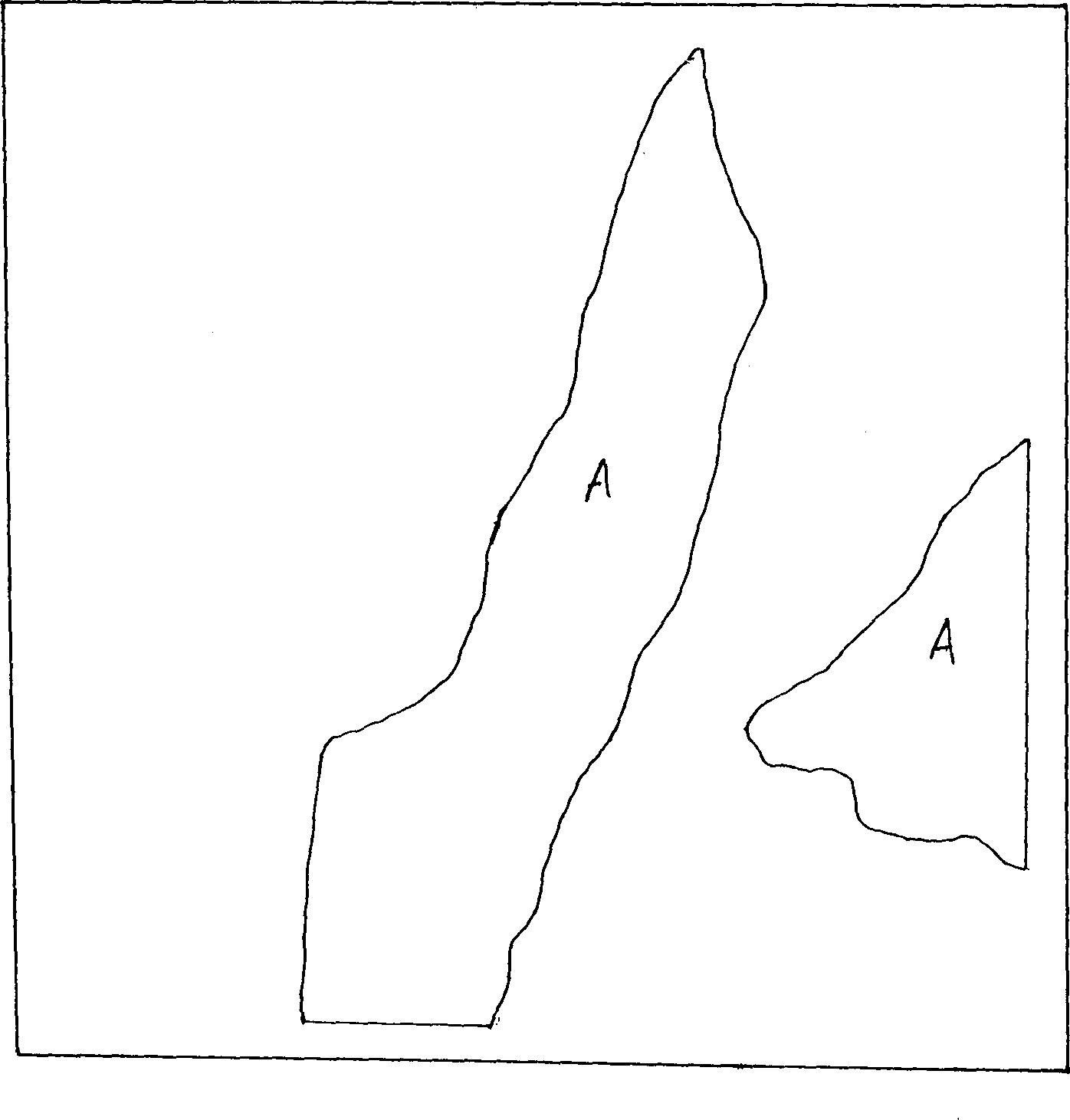

[0031] The specific embodiment: 1. the present invention can adopt Figure 4 The process flow shown is implemented. After the five steps of cloth 1 to cloth 5 are completed, the material cavity is separated from the conveying device and pushed to the press, and the material cavity and brick blank are sent to the press, and the material cavity and brick blank are separated from the bottom plate. In this technological process, the brick blank is not divided into a color material layer and a base material layer. 2. The present invention can also adopt Figure 5 The process flow diagram shown is implemented. In the three steps of Fabric 1, Fabric 2 and Fabric 3, respectively use figure 1 , figure 2 and image 3 In the template 1, template 2, and template 3 shown, A in the figure is the hollow hole. The hollow holes of the three templates are spliced together to form a complete pattern. The template is made of stainless steel plate with a thickness of 3-8mm. For fabric, pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com