Integrated natural gas treating apparatus

A technology for comprehensive treatment and natural gas, which is applied in the fields of gas fuel, liquid hydrocarbon mixture recovery, lighting and heating equipment, etc. It can solve the problems of impossible quantity, expensive investment, burning of chemical raw materials, etc., and achieve a simple system and low cost. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

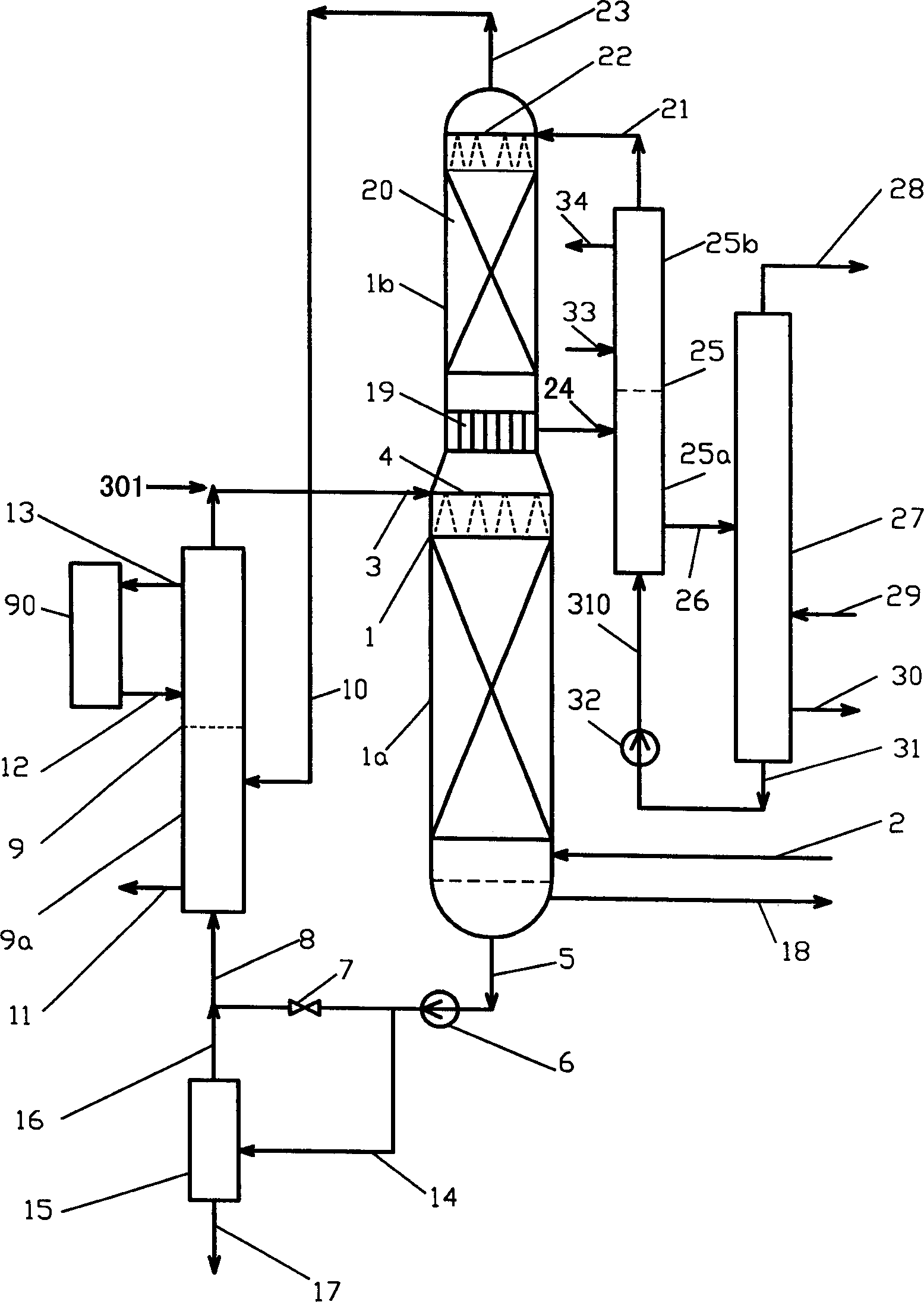

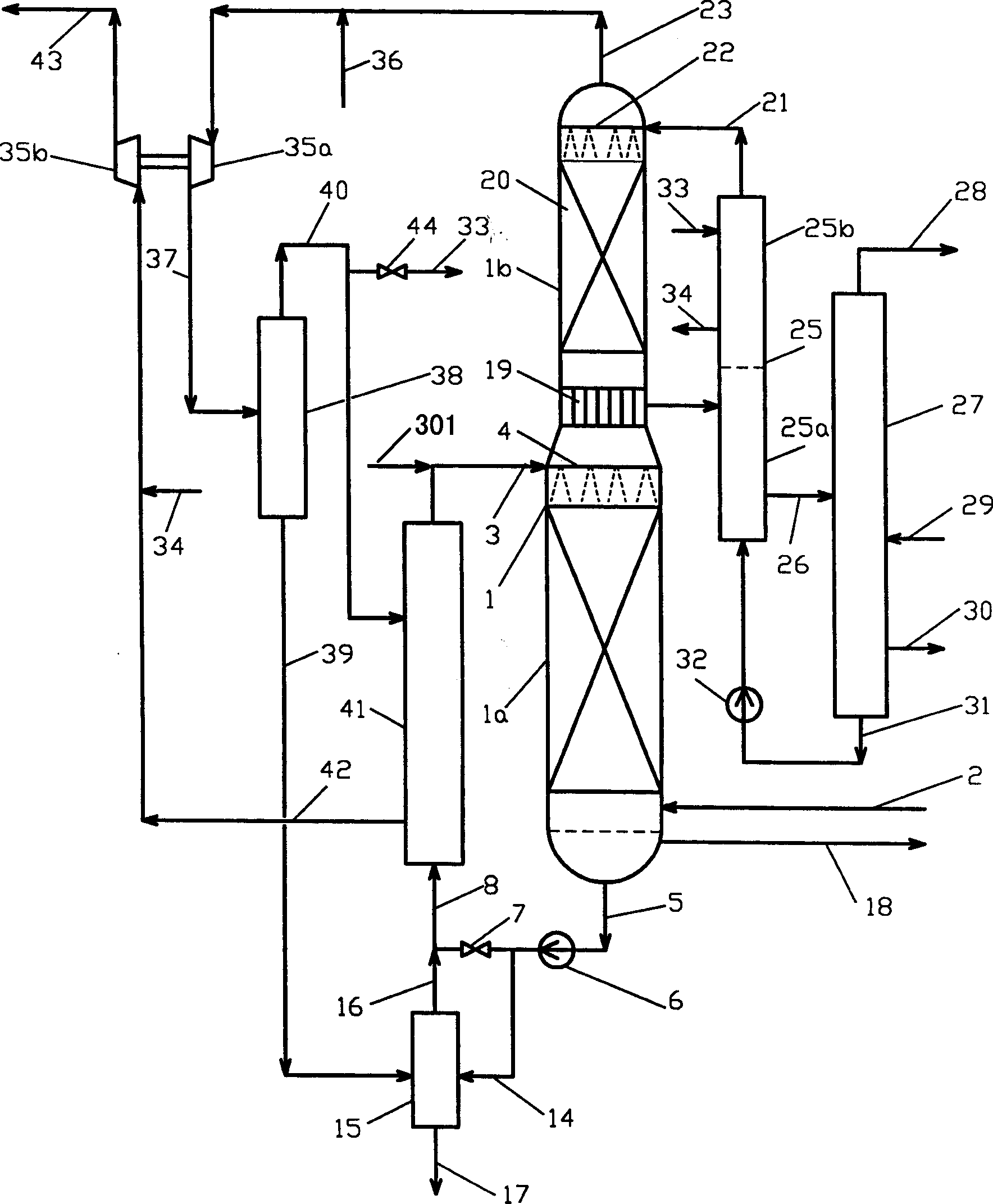

[0024] figure 1 It shows the system diagram of the natural gas comprehensive processing device proposed by the present invention, which adopts industrial refrigeration equipment as the cold source. The core equipment in the device is a comprehensive processor 1 (hereinafter referred to as "processor"), which is further divided into a dehydration section 1a and a separation section 1b.

[0025] Raw natural gas containing saturated water vapor and various light oil components (hereinafter referred to as "raw gas") enters the dehydration section 1a through the inlet pipe 2 at the lower part of the processor 1 and flows upward.

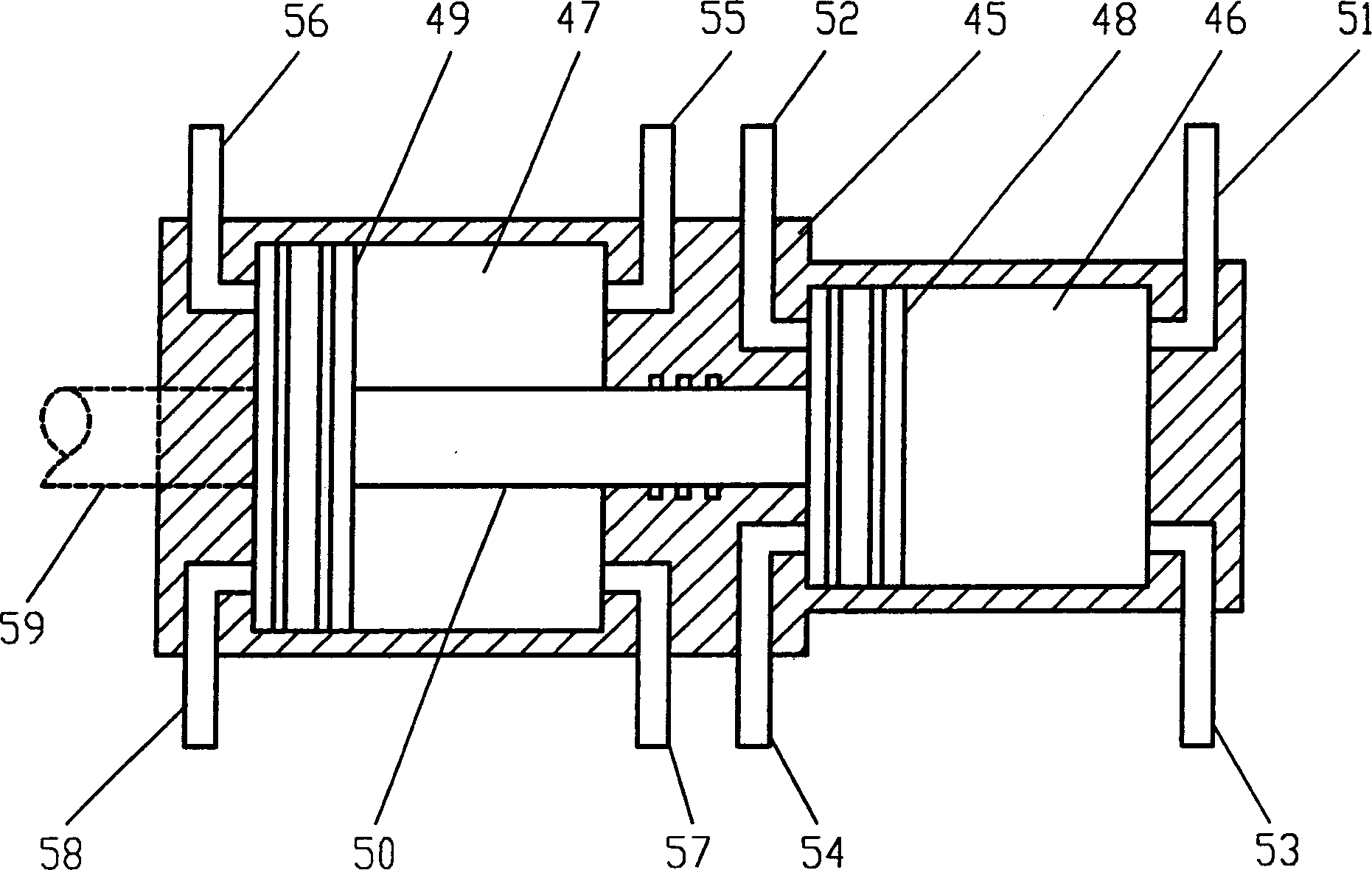

[0026] A liquid heat-carrying working medium (hereinafter referred to as "working medium") containing a hydrate inhibitor (hereinafter referred to as "inhibitor") enters the heat-carrying medium in the dehydration section 1a from the heat-carrying medium inlet pipe 3 at the upper part of the dehydration section 1a. The working fluid distributor 4 sprays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com