Pressed Fe-Ni alloy and Fe-Ni-Co alloy thin belt for planar aperture mask

A press-forming, iron-nickel-cobalt technology, applied to electrical components, circuits, cathode ray tubes/electron beam tubes, etc., can solve the problems of increased raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

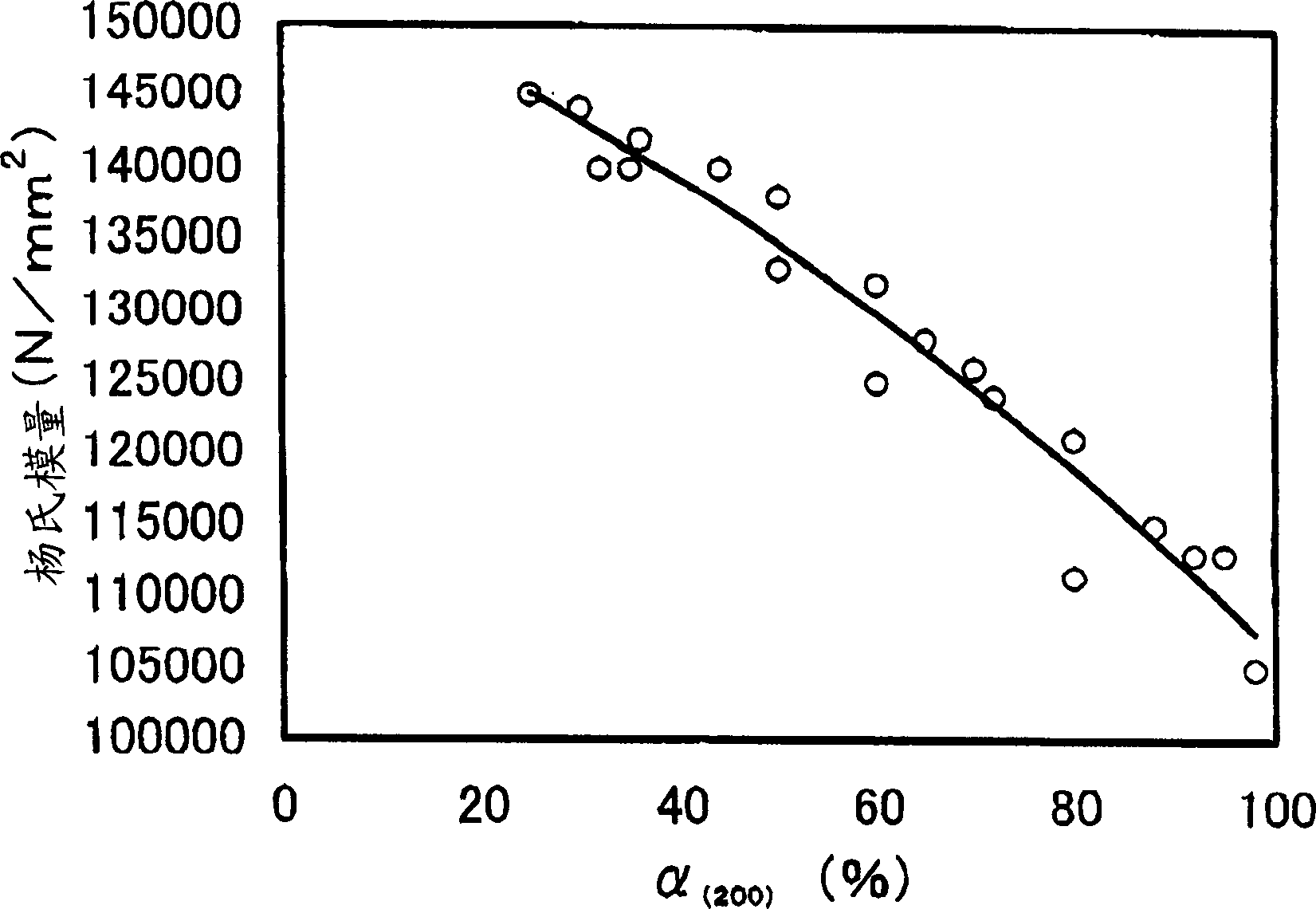

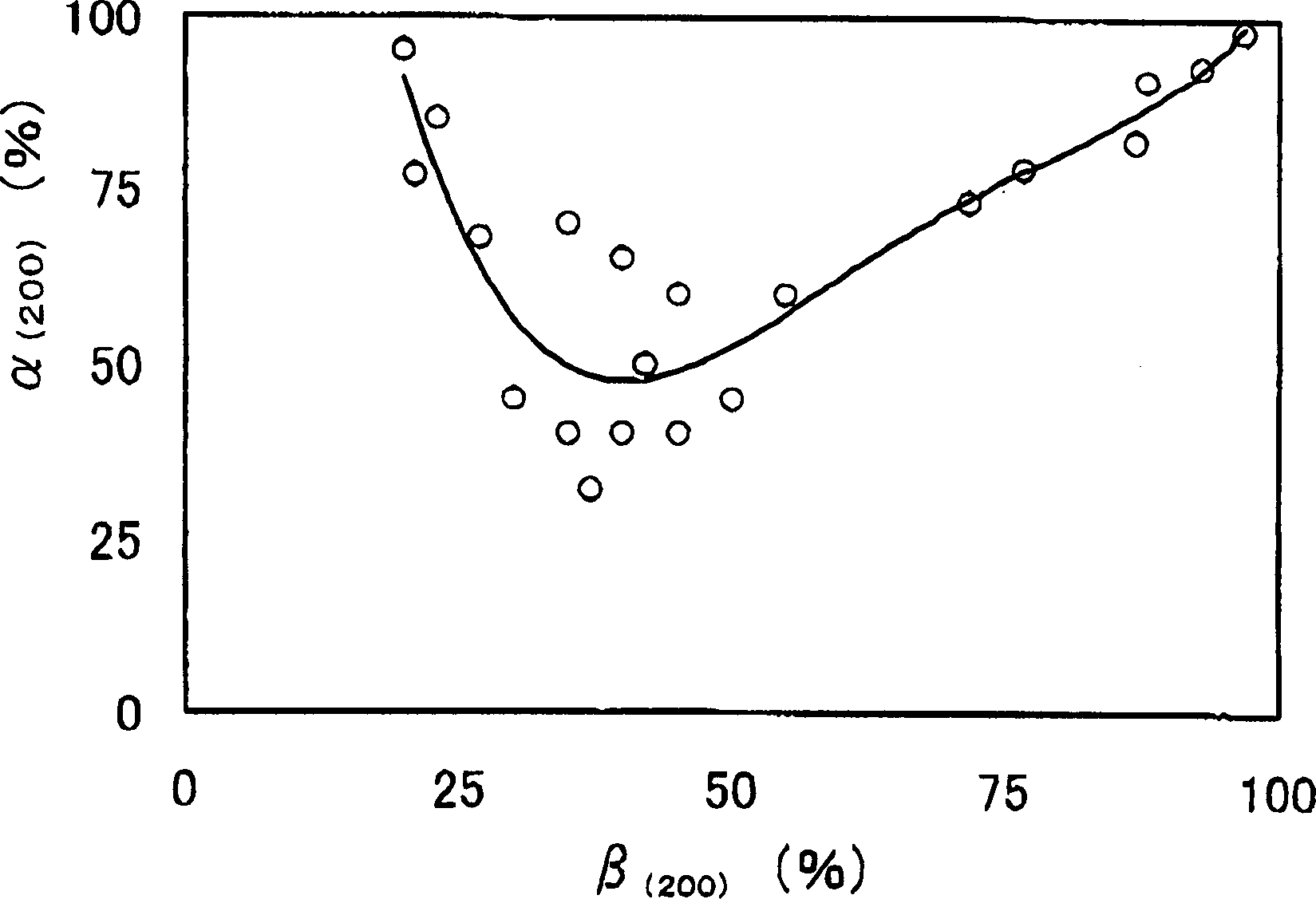

[0086] (1) Example 1: Iron-nickel alloy

[0087] Table 3 shows examples and comparative examples related to iron-nickel alloys.

[0088] sample

No

Alloy No.

α (200) %

β (200) %

Young's modulusN / mm 2

Average coefficient of thermal expansion α (30~100℃)

×10 -7 / ℃

etched surface

state

Reality

Shi

example

1

1

45

30

140000(○)

7.5(○)

(○)

2

2

40

38

145000(○)

8.9(○)

(○)

3

3

32

36

147000(○)

8.2(○)

(○)

right

Compare

example

4

8

40

30

105000(×)

48.0(×)

(○)

5

9

45

35

128000(○)

32.0(×)

(○)

6

10

40

35

116000(×)

16.0(×)

(○)

7

1

45

45

112000(×)

8.7(○)

(○)

8

2

55

50

141000(○)

12.8(×)

(×)

9 ...

Embodiment 2

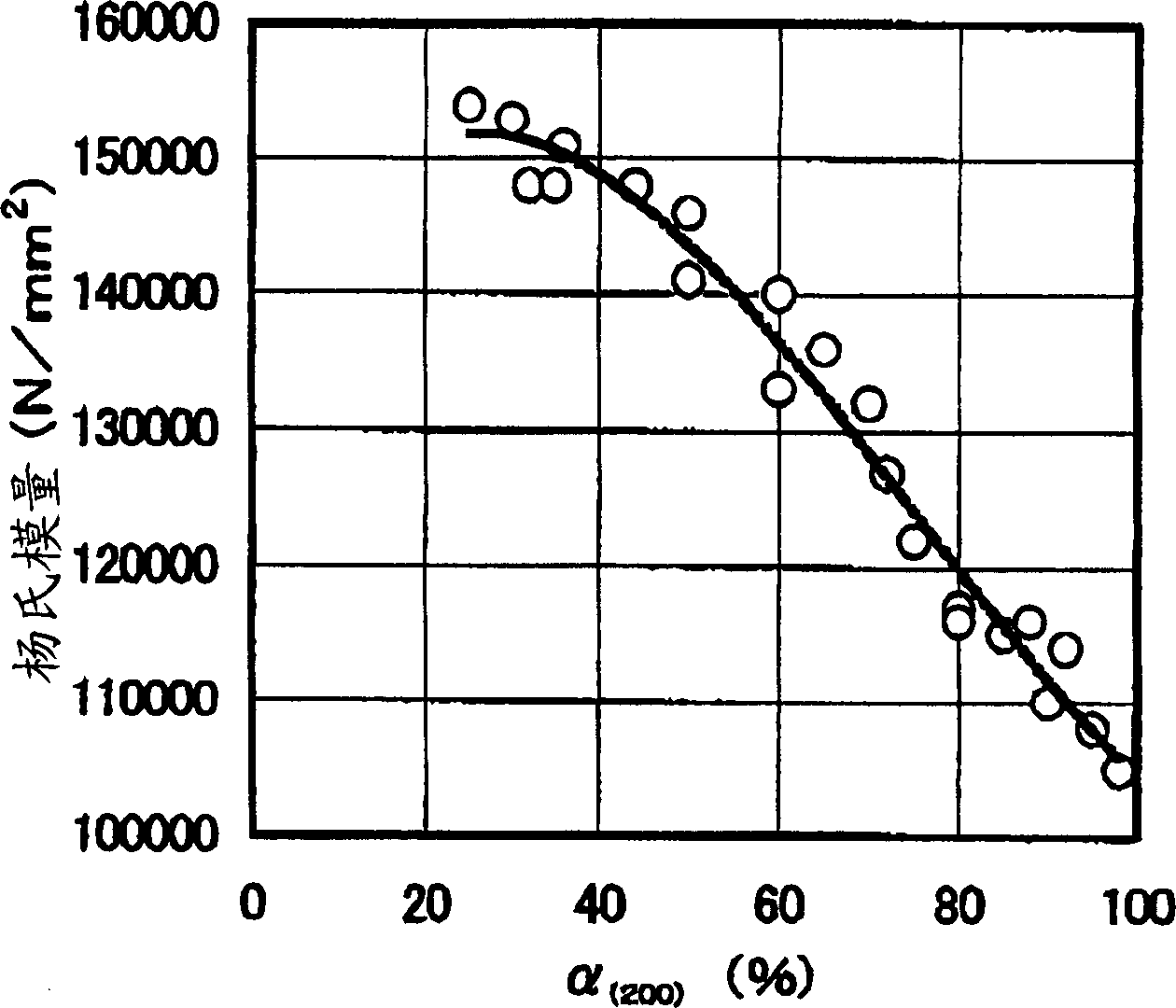

[0094] (2) Embodiment 2: iron-nickel-cobalt alloy

[0095] Table 4 shows examples and comparative examples concerning iron-nickel-cobalt alloys.

[0096] sample

No

No

α (200)

%

β (200) %

Young's modulusN / mm 2

Average coefficient of thermal expansion α (30~

100℃)×10 -7 / ℃

State of etched surface

send

Bright

example

18

18

40

42

148000(○)

3.1(○)

(○)

19

19

30

40

152000(○)

3.0(○)

(○)

20

20

32

30

154000(○)

3.9(○)

(○)

21

21

32

40

158000(○)

6.5(○)

(△)

22

22

50

32

142000(○)

6.8(○)

(△)

23

23

40

45

141000(○)

3.3(○)

(△)

24

24

55

30

136000(○)

5.9(○)

(△)

25

25

50

60

137000(○)

3.1(○)

(△)

26

26

55

25

1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com