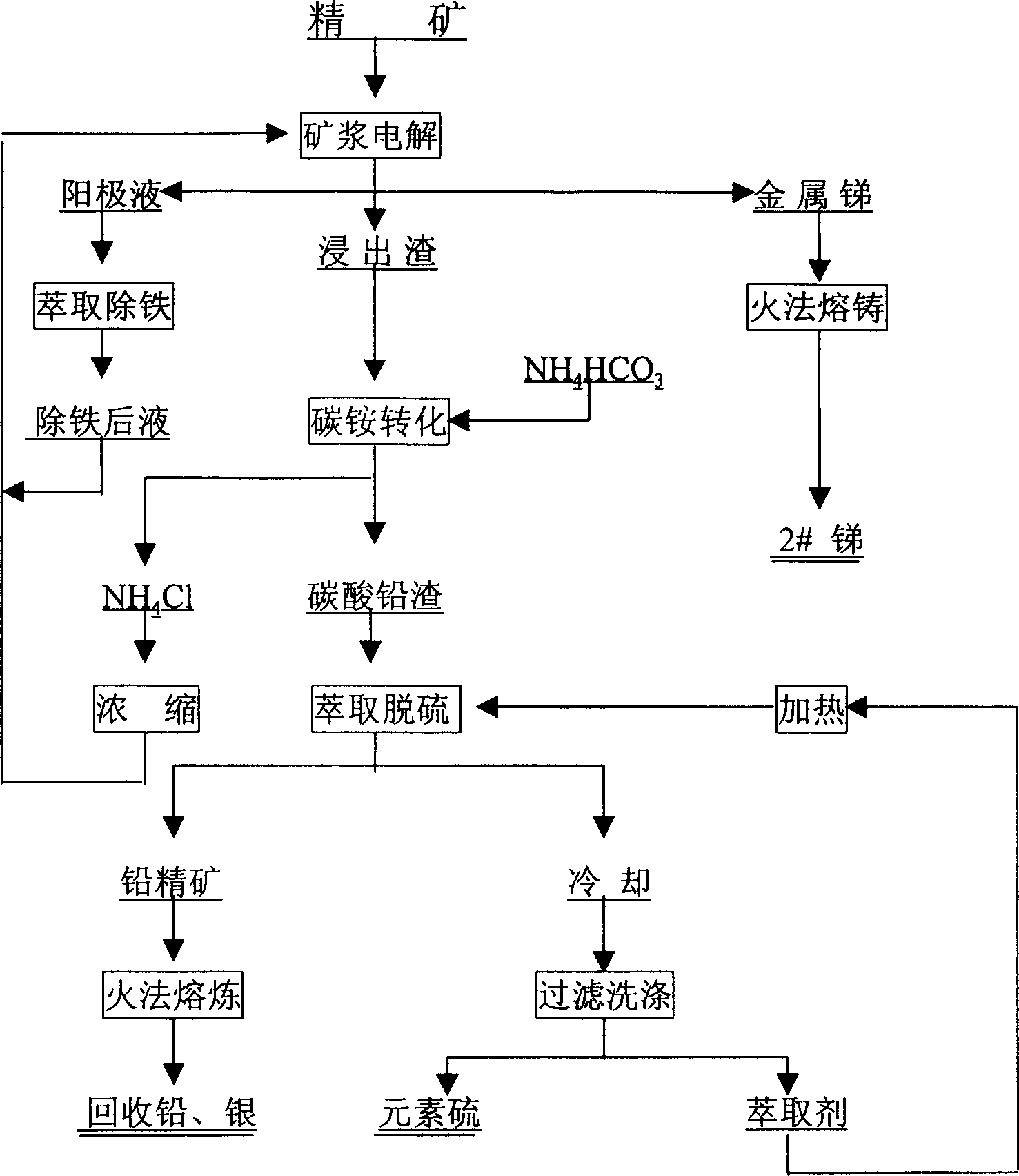

Process for preparing antimony by electrolyzing slurry of sulfide ore containing antimony

A technology of pulp electrolysis and antimony vulcanization, which is applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of unsuitability, large volatilization of sodium sulfide, and high leaching temperature, and achieves convenient storage and transportation, and reduces volatilization loss. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Composition of complex antimony concentrate used: Sb23.4%, Fe14.7%, S23.57%, Pb27.8%. The slurry electrolytic leaching conditions are as follows: antimony concentrate particle size -50μm accounts for more than 90%, take 100g ore sample for electrolysis in a 5L slurry electrolytic cell, leaching temperature is 60°C, hydrochloric acid concentration is 30g / L, ammonium chloride concentration is 200g / L, The antimony concentration is 50g / L, and the cathode current density is 150A / m 2 . The amount of electricity supplied is the theoretical amount required by antimony oxide.

[0025] The leaching rate of antimony was 99.12%, the antimony cathode contained 98.78% antimony and 0.02% lead.

Embodiment 2

[0027] Composition of complex antimony concentrate used: Sb16.1%, Fe11.2%, S18.8%, Pb19.8%. The slurry electrolytic leaching conditions are as follows: antimony concentrate particle size -74μm accounts for more than 70%, take 100g of ore samples for electrolysis in a 5L slurry electrolytic cell, the leaching temperature is 30°C, the concentration of hydrochloric acid is 20g / L, and the concentration of ammonium chloride is 150g / L. The antimony concentration is 40g / L, and the cathode current density is 160A / m 2 . The amount of electricity supplied is the theoretical amount required by antimony oxide.

[0028] The leaching rate of antimony was 96.58%, the antimony cathode contained 98.98% antimony and 0.021% lead.

Embodiment 3

[0030] Composition of complex antimony concentrate used: Sb28.5%, Fe16.5%, S24.7%, Pb34.6%. The conditions of pulp electrolytic leaching are as follows: antimony concentrate particle size -74μm accounts for more than 70%, take 100g of ore samples and carry out pulp leaching electrolysis in a 5L pulp electrolytic tank, the leaching temperature is 50°C, the concentration of hydrochloric acid is 15g / L, and the concentration of ammonium chloride is 250g / L L, antimony concentration is 30g / L, cathode current density is 180A / m 2 . The amount of electricity supplied is the theoretical amount required by antimony oxide.

[0031] The leaching rate of antimony was 97.18%, the antimony cathode contained 97.57% antimony and 0.024% lead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com