Frequency-dividing self-mixing feedback-type non-contact He-Ne laser micrometer

A laser feedback and frequency splitting technology, applied in lasers, laser parts, instruments, etc., can solve the problems of inability to determine direction, no subdivision function, etc., and achieve the effects of low cost, simple structure and large measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

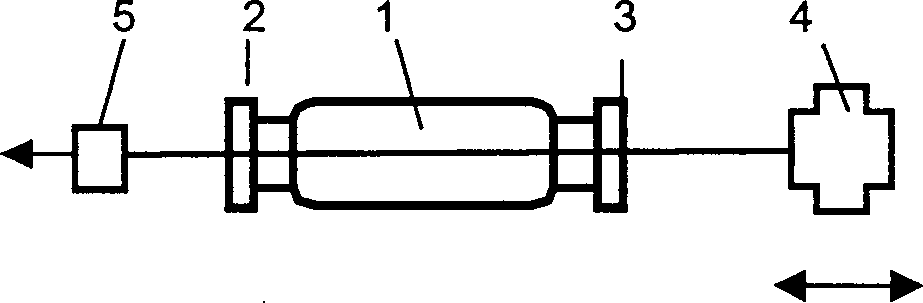

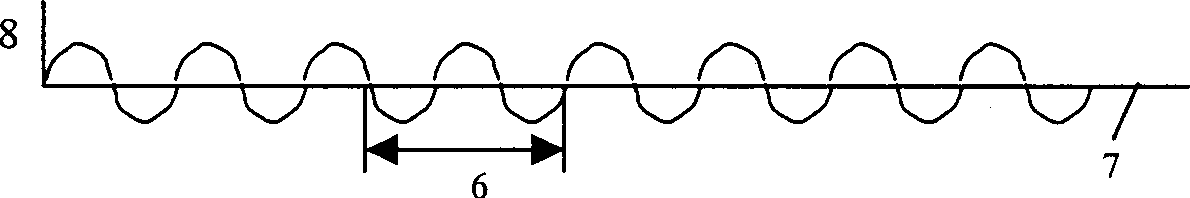

[0030] figure 1 It is the general structure diagram of the existing laser feedback effect interferometer. figure 2 It is a schematic diagram of the general output curve of the existing laser feedback effect, and shows the change of laser power when the distance between the feedback mirror and the laser output mirror changes.

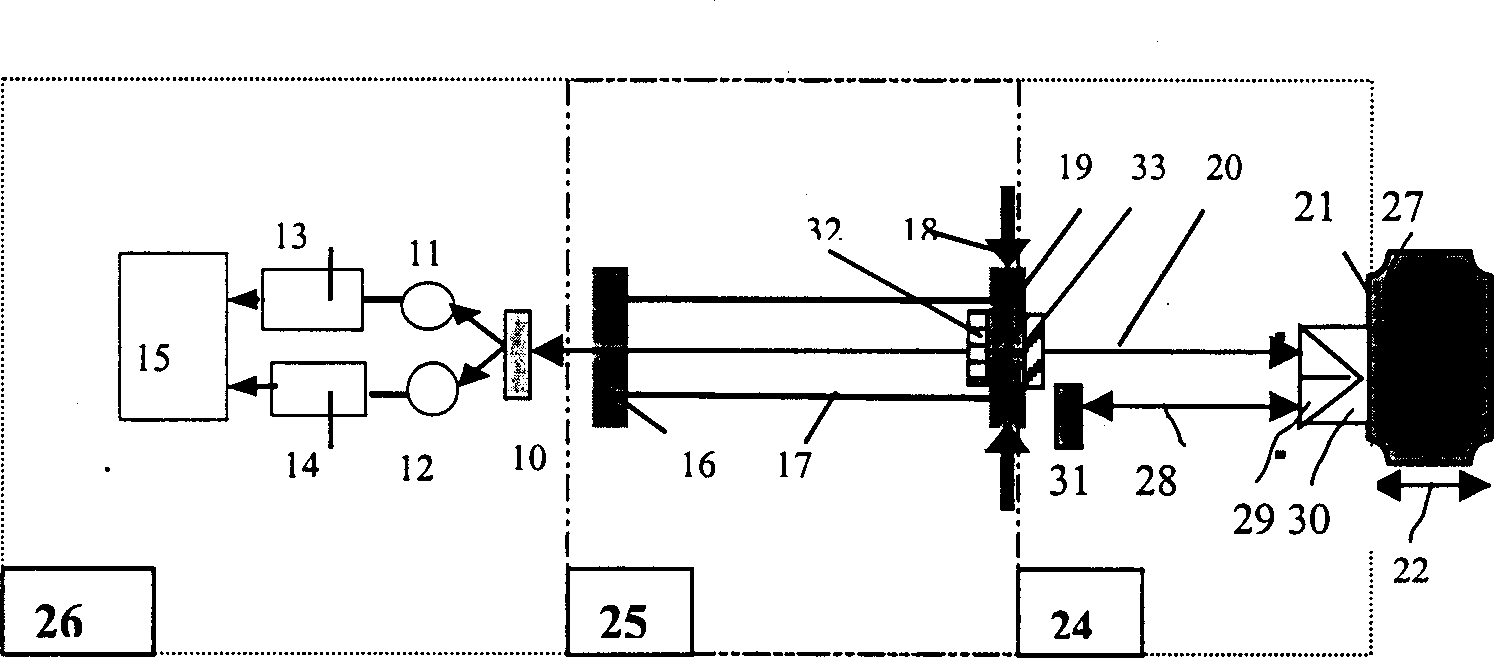

[0031] Figure 3.1It is a schematic diagram of the principle structure of the present invention. The frequency-split HeNe laser feedback self-mixing non-contact micrometer consists of three parts: a photoelectric detection and processing unit 26 , a frequency-split HeNe laser light source 25 and a prism folding feedback cavity 24 . The object to be measured is 27 . The photoelectric detection and processing unit 26 includes a polarization beam splitter 10 sequentially arranged in the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com