Multi-purpose cutting-sawing machine

A technology for cutting saws and saw blades, applied in the field of thin plate sawing appliances, can solve the problems of single function and purpose, not smooth incision, inability to realize cutting and sawing at the same time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

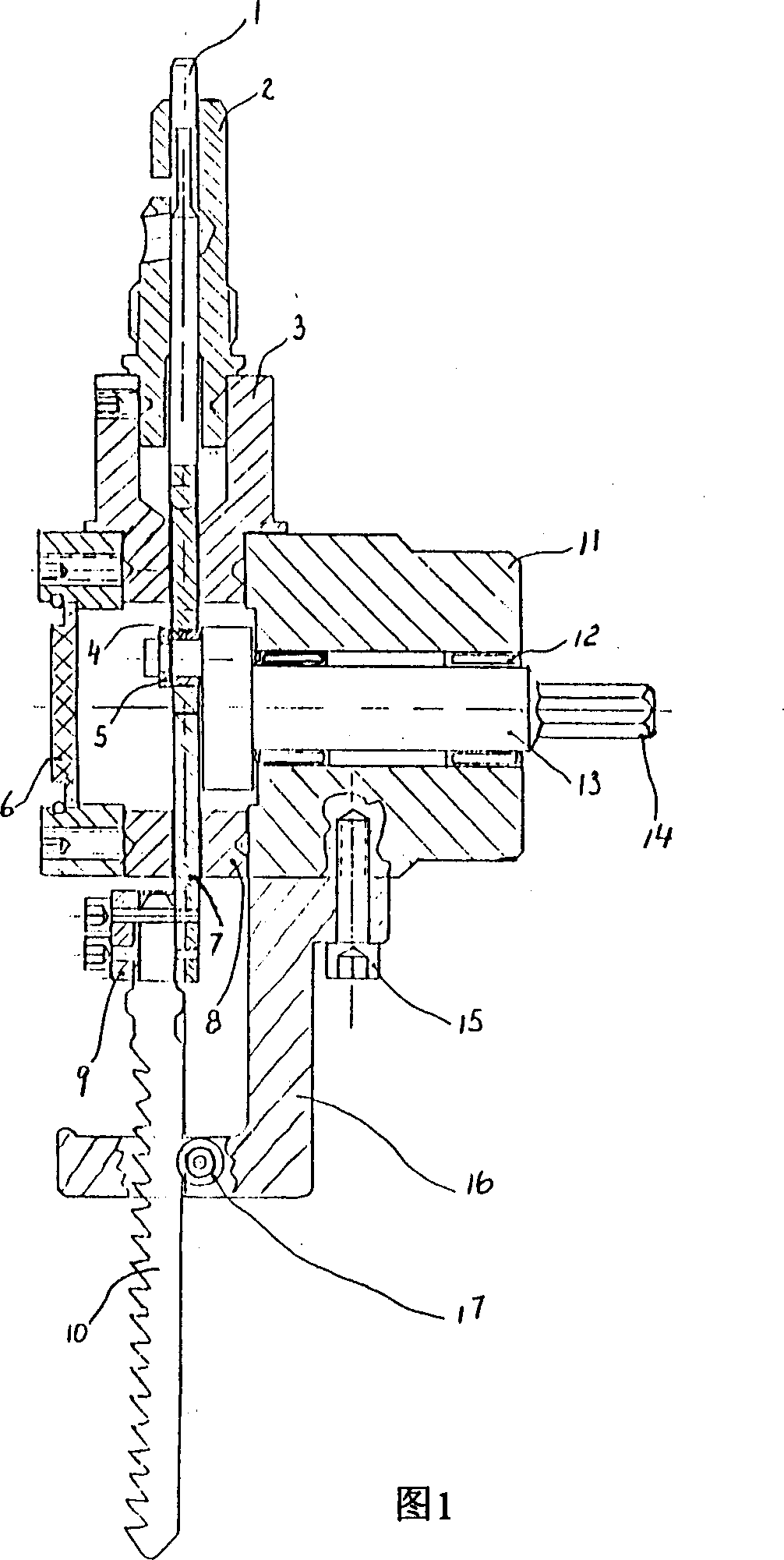

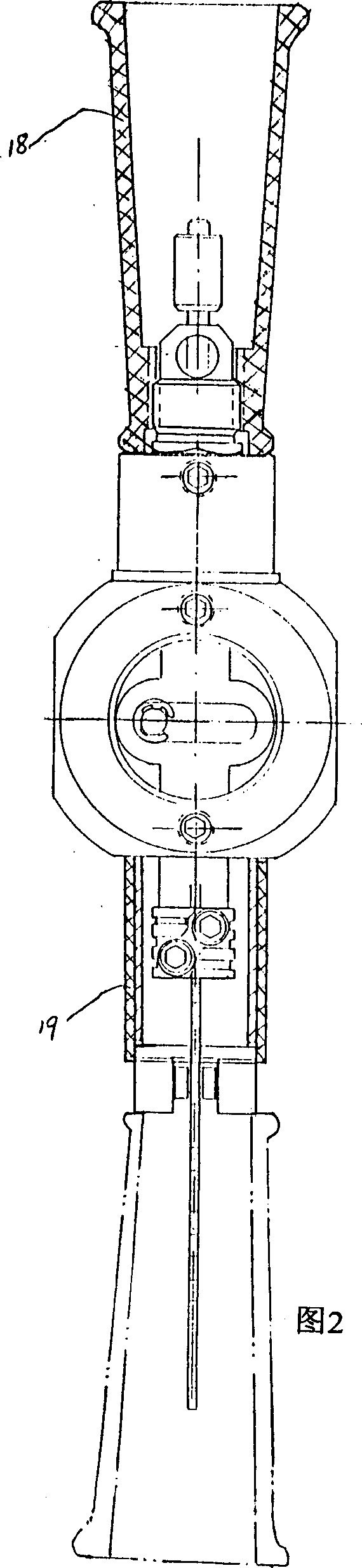

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] As shown in Figures 1-3, the present invention is used in conjunction with electric and pneumatic tools (such as pistol electric drills), which can cut metal sheets below 1.5 mm, and the cutting speed is 3000 rpm-2M / min; Milling plastic boards, fiberboards, wooden boards and other non-metallic plates and bars below 50 mm, the sawing and milling speed is 3500 rpm-1M / min; in exchange for saw blades, it can saw and mill metal strips below 20 mm, cutting The speed is fast, and the sawing and milling speed can reach 300 rpm-0.05M / min.

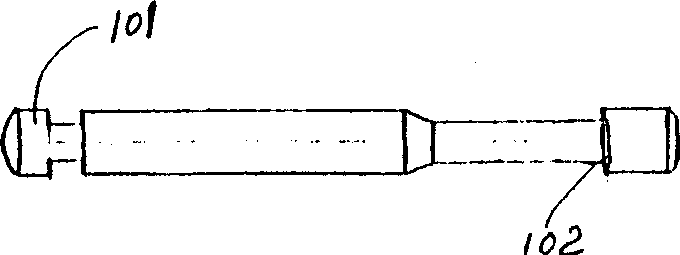

[0016] This multipurpose sawing machine has a polygonal or cylindrical housing 11, and the housing has coaxial shaft holes that are perpendicular to each other and penetrate each other. In the horizontal direction shaft hole of FIG. An eccentric shaft 13 with an eccentricity of 5-10 mm driven by external force (electric and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com