Adaptive 2-hoop fibre array load and its preparing process

An adaptive, pinching technology, applied in the direction of electrical components, plasma, etc., can solve the problems of destroying the specific distribution of the wire array load wire, unsuitable load, large contact resistance, etc., and achieves easy installation and removal, easy assembly, The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

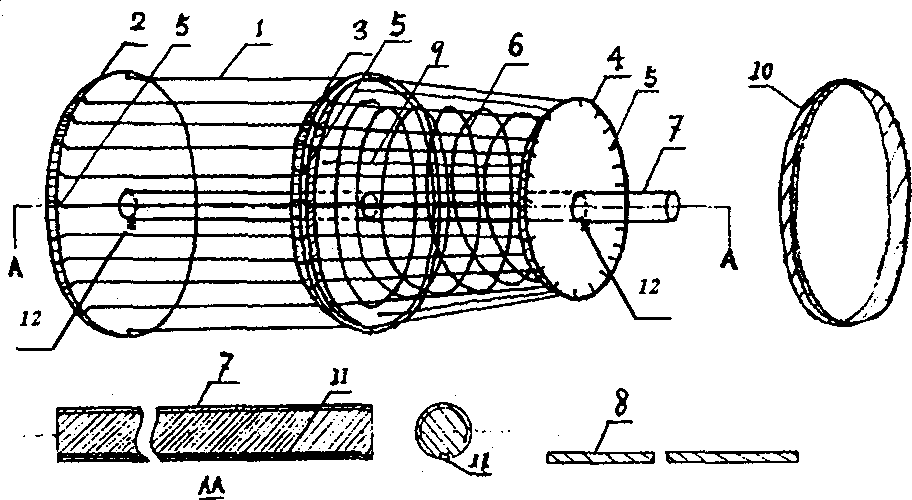

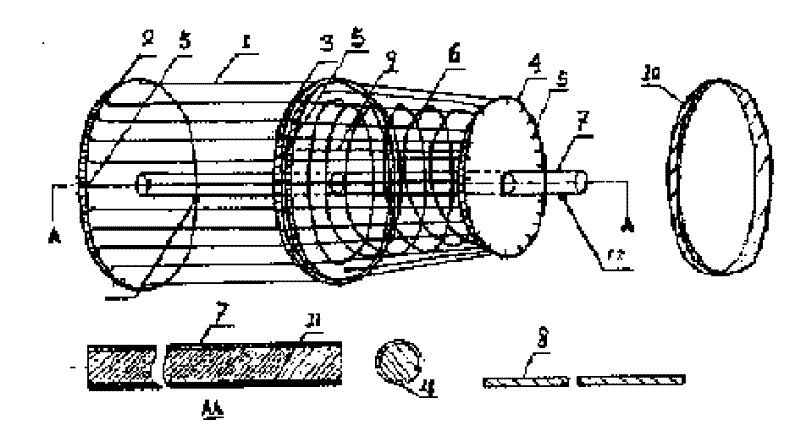

[0032] From figure 1 It can be seen that the embodiment of the present invention is a cylindrical single-layer self-adaptive Z-pinch wire array load.

[0033] Positioner a2, positioner b3 and auxiliary positioning plate 4 are made of brass disc material; one side of positioner b3 is processed into a coaxial cylindrical step, and the diameter of the step is smaller than the outer diameter of positioner b3.

[0034] The axial center of locator a2, locator b3 and auxiliary locating disc 4 are processed with threads of the same pitch along the axial direction, and a keyway 12 is processed along the axial direction; Cut out the same number of slits 5 evenly distributed on the respective circumferences.

[0035] The compression ring 10 has a diameter smaller than the outer diameter of the locator b3, slightly larger than the diameter of the step of the locator b3; the elastic size of the spring 6 matches the strength of the load wire 1 loaded by the wire array; the locator a2, the ...

Embodiment 2

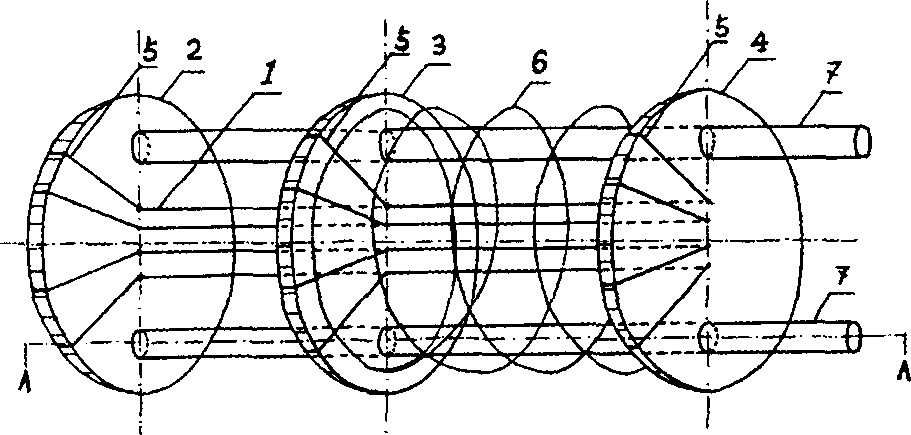

[0041] figure 2 It is a schematic diagram of the load structure of the parallel multi-filament self-adaptive Z-pinch wire array of Embodiment 2 of the present invention.

[0042] The auxiliary device system with two support rods 7 is adopted, and no steps and compression rings 10 are arranged on the positioner b3, and no wire 9 is used for connection, and the rest are the same as the above-mentioned embodiment 1.

Embodiment 3

[0044] The slit 5 is replaced by a small hole, and the load wire 1 is connected through the small hole, and the rest is the same as the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com