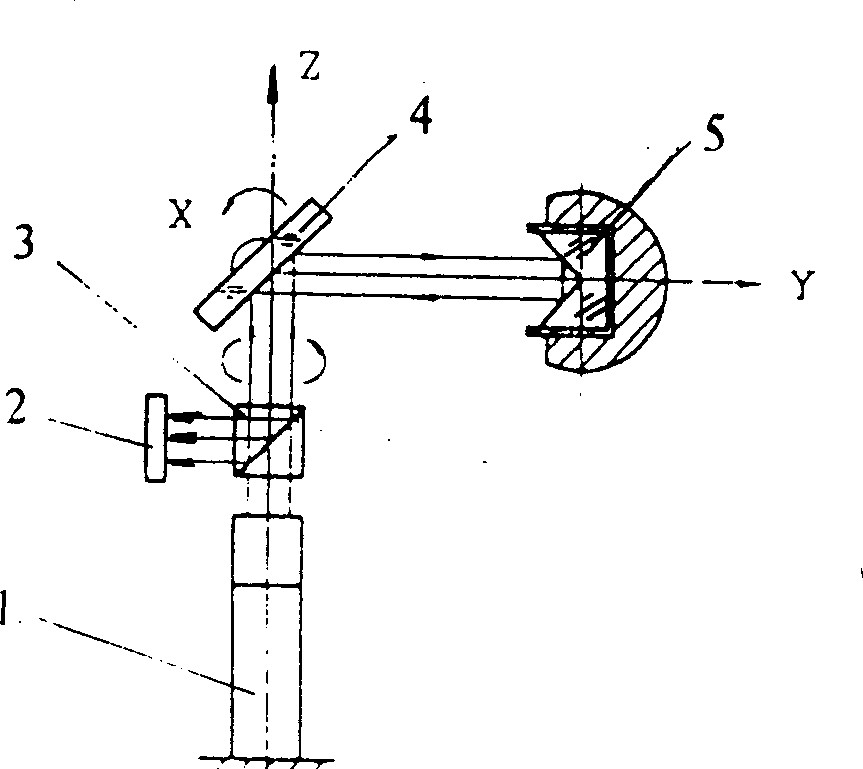

Laser scannning and tracking instrument with six feedom measurement function

A laser scanning and tracker technology, applied in the direction of electromagnetic radiation induction, etc., can solve the problems of inability to achieve measurement, inability to achieve spatial point distance measurement, and inability to carry a point aiming probe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

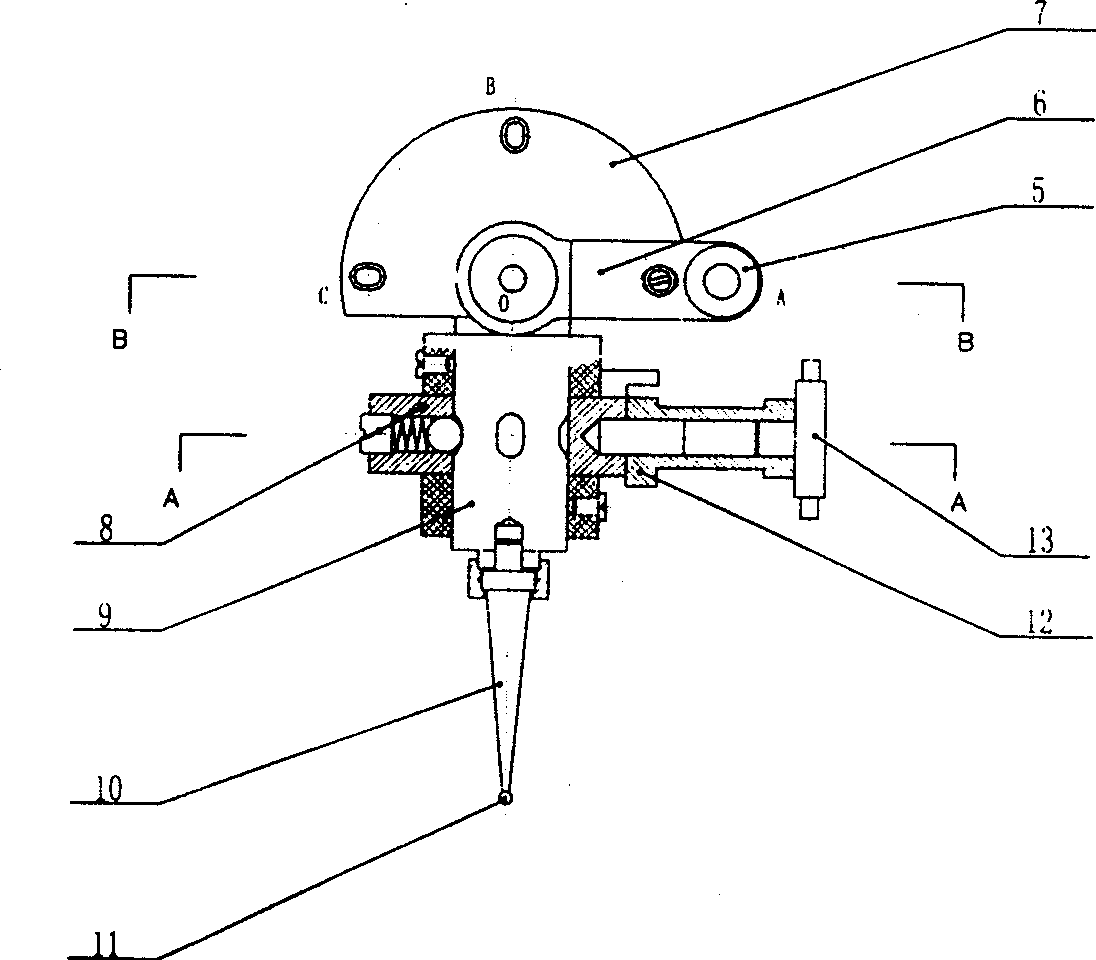

[0017] The principle of the present invention and the process of implementing the measurement are described in conjunction with the accompanying drawings.

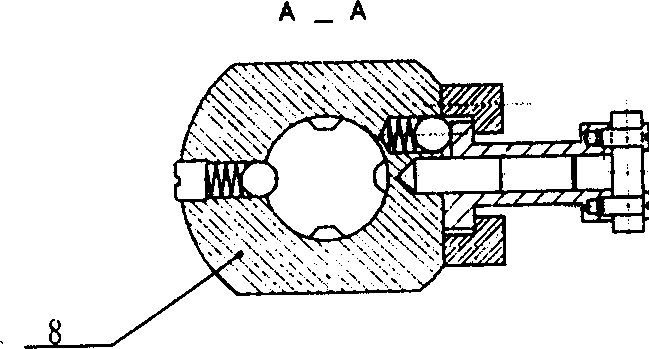

[0018] In the axial plane rotating mechanism carrying the corner cube, the center line of the rotating arm 6 can be accurately positioned at the three positions (OA, OB, OC) of the positioning support plate 7 by the elastic steel ball and the cone socket pair. Therefore, the angle The coordinates of the center of the corner mirror light target at three positions (points A, B, and C in the figure) can be measured and determined on a three-coordinate measuring machine. Let the rotation center O of the axial plane rotation mechanism be the origin of the coordinates, and A(x a 'y a 'z a ’), B(x b 'y b 'z b ’), C(x c 'y c 'z c ’) The coordinate values of the three points constitute the coordinate system of the “three-degree-of-freedom coordinate orientation measurement target” as the reference point. When the coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com