LED module for signaling devices

A component and equipment technology, applied in the field of light-emitting diode components, can solve the problems of inflexible LED matrix and inability to use multiple lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Description of preferred embodiments

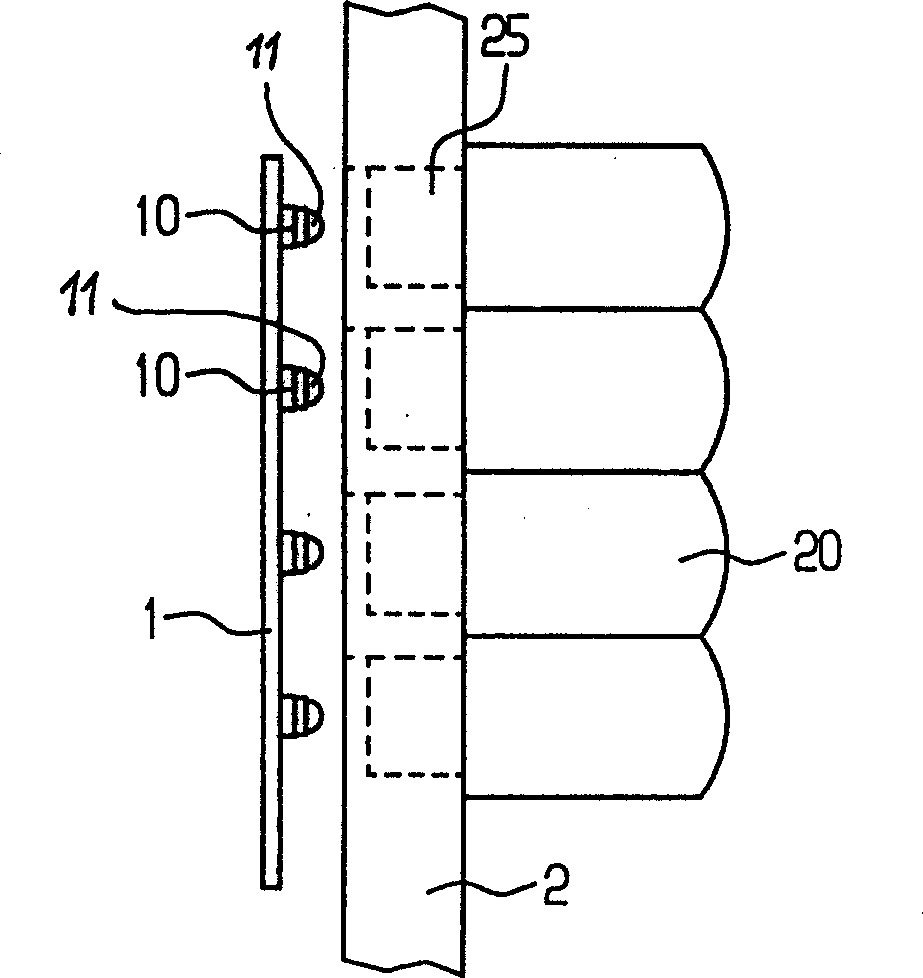

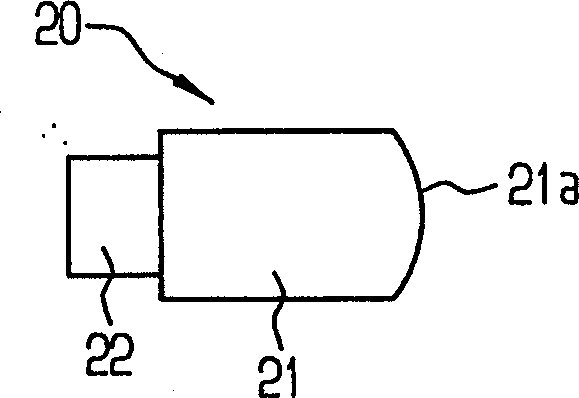

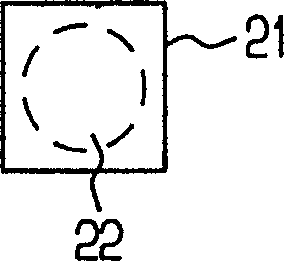

[0025] According to the first configuration of LED assembly of the present invention comprises figure 1 The thin plate 1 and the light substrate 2 in the cross-sectional view are shown. The sheet 1 is provided with a plurality of LEDs 10 arranged in a matrix of LED rows. In order to improve the heat dissipation of the LEDs, the sheet metal 1 is preferably formed from a metal plate, thereby increasing the luminous efficiency of the LEDs. Preferably, the LEDs are mounted on the thin board 1 by surface mount method (SMT). The LED10 can be manufactured according to SIEMENS SMT-TOPLED regulations approved by the German state. It is required that the circuit structure formed by the LED 10 is composed of a plurality of independent circuit branches that are not related to each other. This guarantees a high fail-safety of the assembly, for example, by connecting independent circuit branches each consisting of 15 LEDs 10 in parallel so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com