Engineering mechanism including fine regulation and operation mode

A technology of construction machinery and operation mode, applied in mechanical equipment, cranes, transportation and packaging, etc., to achieve the effect of stable operation performance and operability, and improved operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

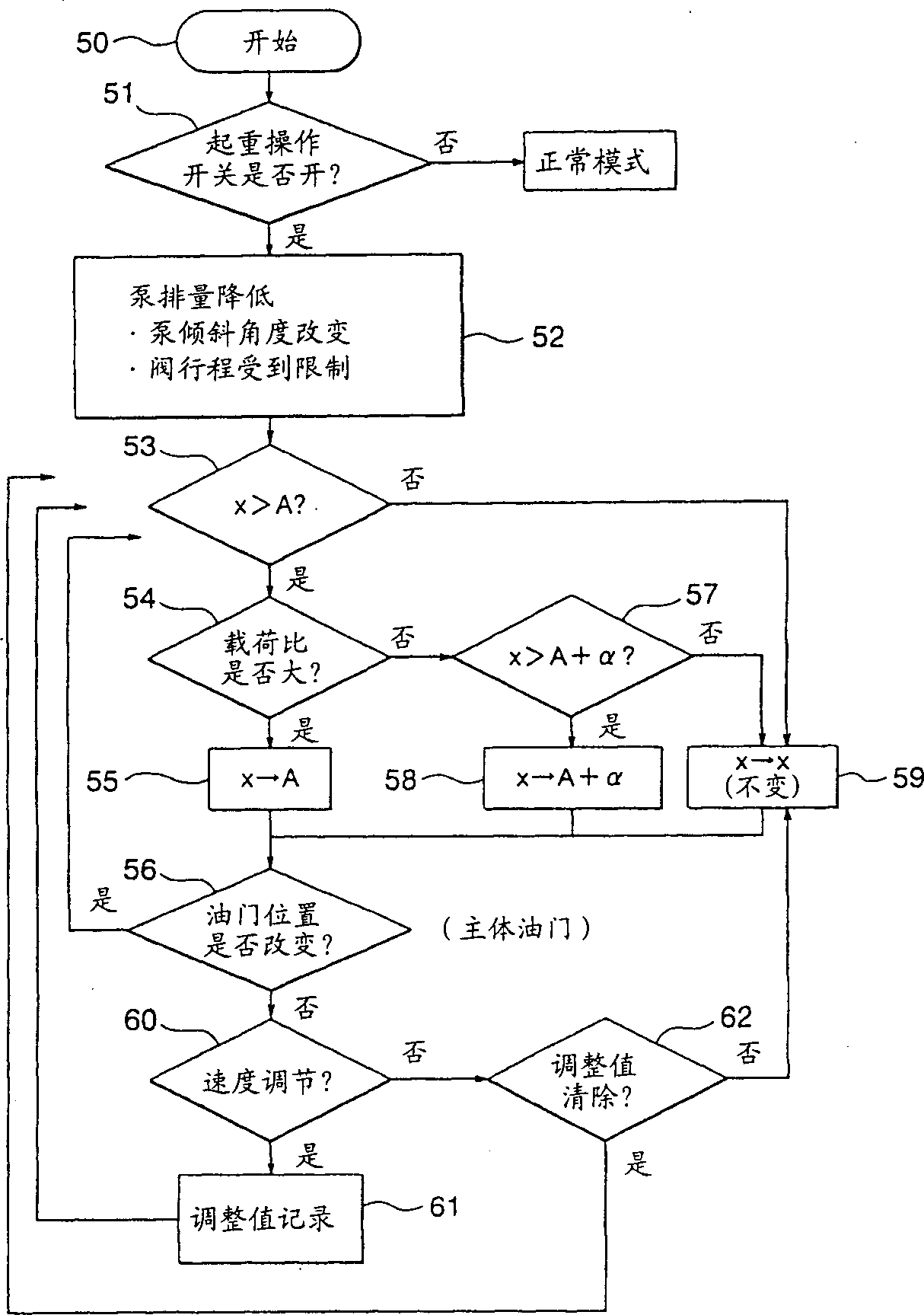

[0025] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

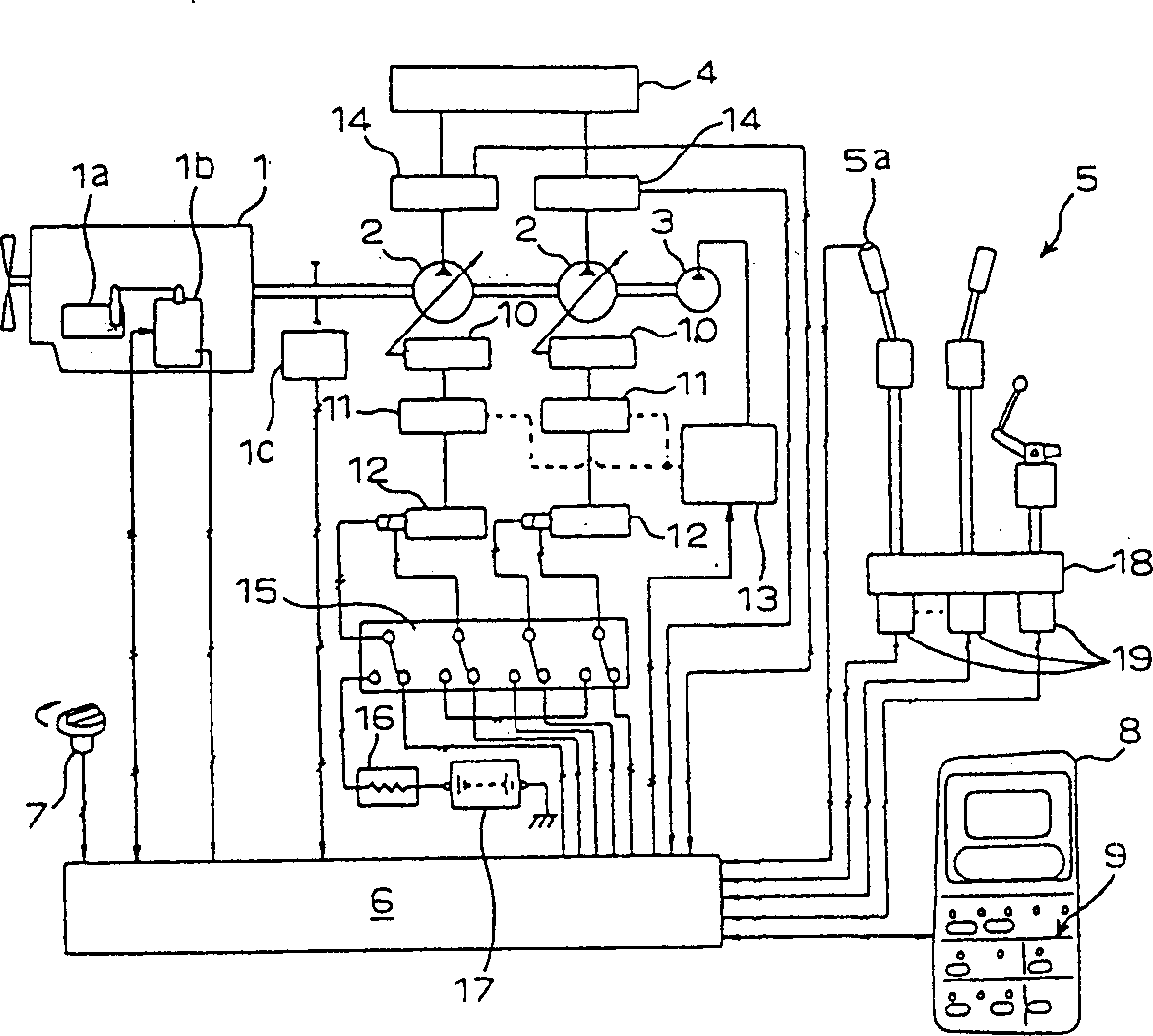

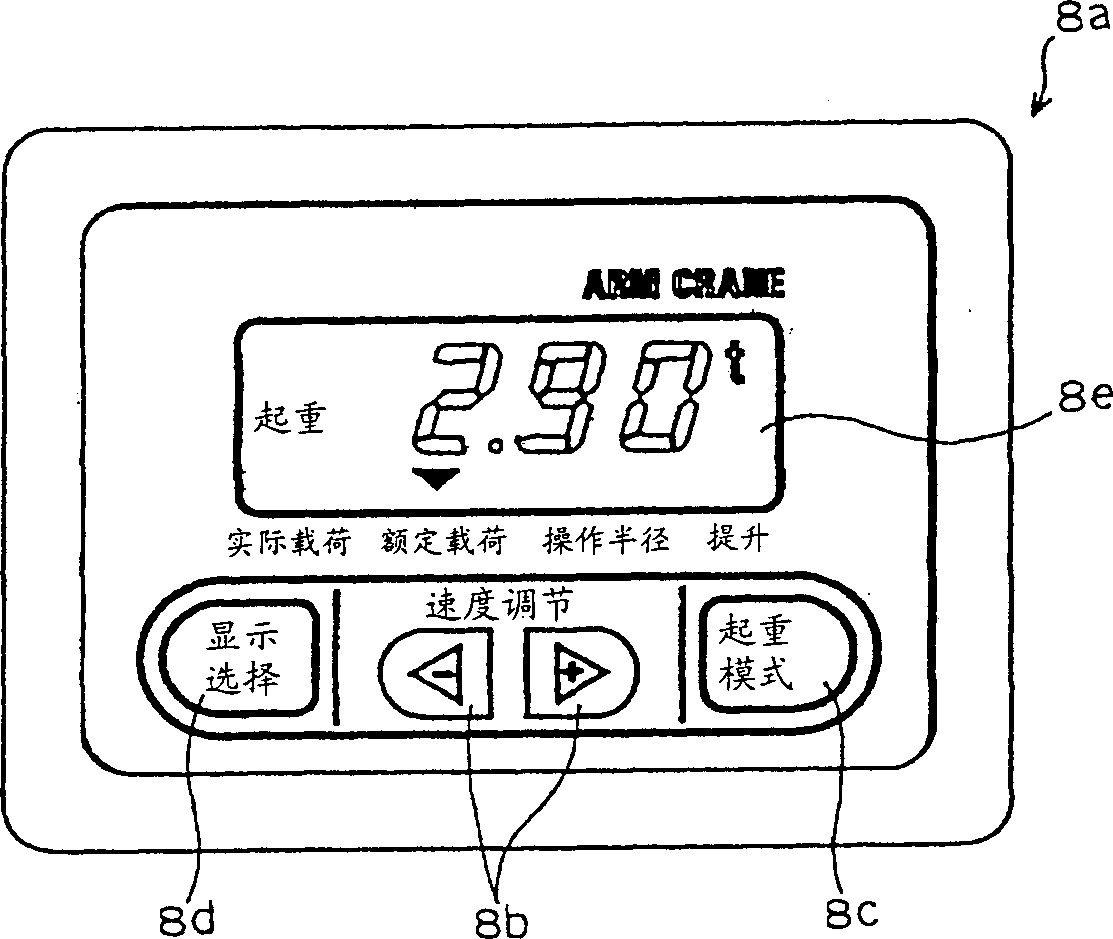

[0026] figure 1 is a control circuit diagram illustrating an electro-hydraulic system with various modes of operation for a hydraulic lift-shovel, which is a representative embodiment of the present invention, figure 2 is a schematic plan view showing an example of the lifting monitor panel applied to the hydraulic excavator described above. Hereinafter, the embodiment will be described by taking the lifting excavator as an example, but the present invention is not limited thereto, and the present invention can also be applied to various construction machines, such as bulldozers and tractor shovels.

[0027] The lifting excavator in this embodiment includes a running body, a revolving body mounted on the running body and rotatable around a vertical axis, and an operating machine arranged on the revolving body. The operating machine includes a main boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com