Process for producing dielectric ceramic composition

A technology for dielectric ceramics and compositions is applied in the field of preparation of dielectric ceramic compositions, which can solve the problems of easy evaporation and difficult calcination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

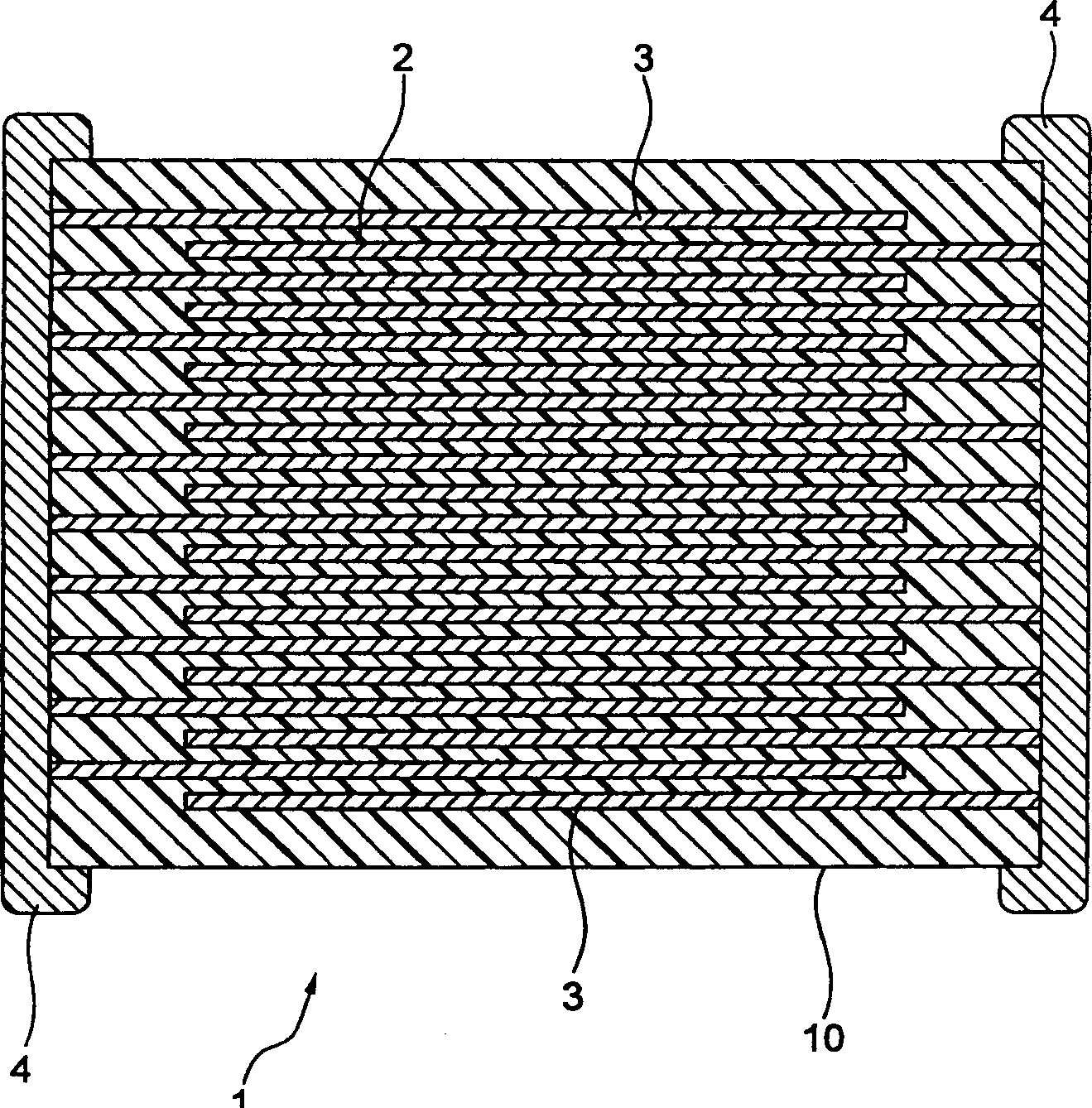

Image

Examples

Embodiment 1

[0214] Multilayer ceramic capacitor samples were produced in the following manner.

[0215] First, the following slurries were prepared.

[0216] Dielectric layer slurry

[0217] Various components of major and minor components having a particle size in the range of 0.1-1 micron are first prepared. Carbonates are used as components of MgO and MnO, and oxides are used as other components. Will (Ba 0.6 Ca 0.4 ) SiO 3 Ingredient used as the second minor component. Note (Ba 0.6 Ca 0.4 ) SiO 3 Wet mixed BaCO by ball mill 3 , CaCO 3 and SiO 2 After 16 hours, the mixture was dried, then fired in the air at 1150°C and further pulverized with a ball mill for 100 hours.

[0218] First, the BaTiO 3 Main components and MgCO 3 The first subcomponents are mixed and the mixture is dried to produce a pre-calcined powder. As shown in Table 1, relative to 100 moles of Ba m TiO 2+m , the pre-calcined powder contains 0.9 moles of MgCO 3 , In addition, when detecting the molar ra...

Embodiment 2

[0270] BaTiO 3 Main component, MgCO 3 The first subcomponent and Y 2 o 3 The fifth subcomponent is mixed and the mixture is dried to prepare a pre-calcined powder. As shown in Table 1, relative to 100 moles of Ba m TiO 2+m , the pre-calcined powder contains 0.9 moles of MgCO 3 and 0.5 mol Y 2 o 3 . When detecting the molar ratio of the specific components (Ba+Mg+Ca+Sr) / (Ti+Yb+Y) in the pre-calcined powder, as shown in Table 1, it is 0.999. The molar ratio of (Ba+Yb+Y) / (Ti+Mg+Ca+Sr) was found to be 1.001, as shown in Table 1.

[0271] Next, the calcined powder was calcined in the same manner as in Example 1 to prepare cylindrical samples and capacitor samples, except that as shown in Table 2, 3.0 moles (Ba 0.6 Ca 0.4 ) SiO 3 , 0.374 mol MnCO 3 , 0.1 mole V 2 o 5 , 2.1 mol Yb 2 o 3 and 1.5 moles of Y 2 o 3 , and carry out the same test as in Example 1. The results are shown in Table 3 and Figure 4 middle.

Embodiment 3

[0273] BaTiO 3 Main component, MgCO 3 The first minor component and Yb 2 o 3 The fourth subcomponent is mixed and the mixture is dried to prepare a pre-calcined powder. As shown in Table 1, relative to 100 moles of Ba m TiO 2+m , the pre-calcined powder contains 0.9 moles of MgCO 3 and 0.5 mol Yb 2 o 3 . When detecting the molar ratio of the specific components (Ba+Mg+Ca+Sr) / (Ti+Yb+Y) in the pre-calcined powder, as shown in Table 1, it is 0.999. The molar ratio of (Ba+Yb+Y) / (Ti+Mg+Ca+Sr) was found to be 1.001, as shown in Table 1.

[0274] Next, the calcined powder was calcined in the same manner as in Example 1 to prepare cylindrical samples and capacitor samples, except that as shown in Table 2, 3.0 moles of (Ba 0.6 Ca 0.4 ) SiO 3 , 0.374 mol MnCO 3 , 0.1 mole V 2 o 5 , 1.6 mol Yb 2 o 3 and 2.0 moles Y 2 o 3 , and carry out the same test as in Example 1. The results are shown in Table 3 and Figure 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com