Casting head for solution preparing of film

A solution film forming and casting die technology, applied in the direction of coating, etc., can solve the problems of foreign matter adhesion failure, support peeling residue, and productivity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

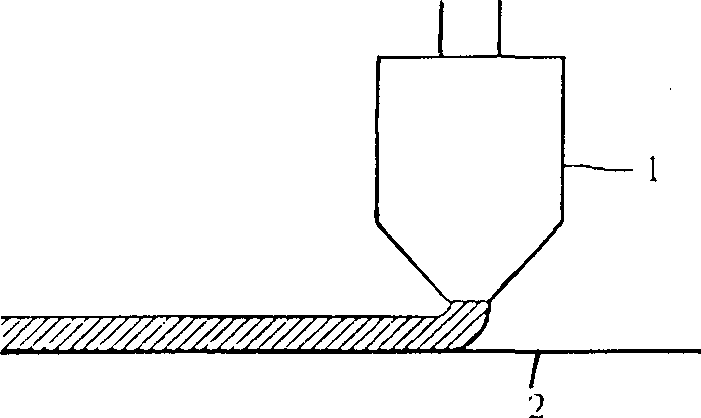

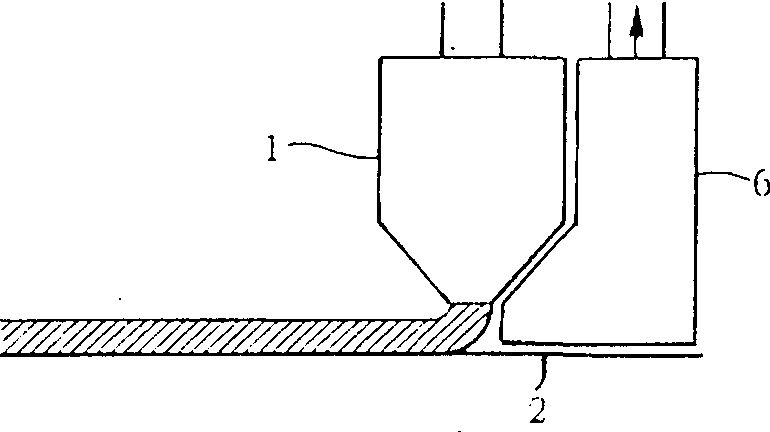

[0106] Single-layer casting was performed under the following conditions. A backing plate with a curved cross-sectional shape is inserted into the lip end.

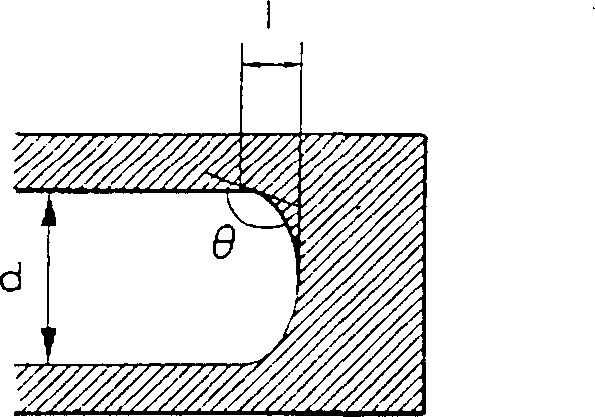

[0107] 1) The angle θ=120 degrees formed by the lip surface and the lip side

[0108] 2) The minimum radius of curvature of the lip side = 0.5mm

[0109] Skin formation occurred at 2 minutes. The amount of occurrence is small, and the crust is difficult to grow into an icicle shape. Almost no peeling on the support

[0110] away from residual dirt.

Embodiment 2

[0112] Single-layer casting was performed under the following conditions. A backing plate with a curved cross-sectional shape is inserted into the lip end.

[0113] 1) The angle θ=150 degrees formed by the lip surface and the lip side

[0114] 2) The minimum radius of curvature of the lip side = 0.5mm

[0115]Skin formation occurred at 20 minutes. The amount of occurrence is small, and the crust is difficult to grow into an icicle shape. almost no support

[0116] Peel off residual dirt.

Embodiment 3

[0118] Single-layer casting was performed under the following conditions. Machine the lip itself into a curved surface.

[0119] 1) The tangent line from the side of the lip is consistent with the lip surface, forming a smooth curve with no step height difference.

[0120] 2) The minimum radius of curvature of the lip side = 0.5mm

[0121] No skinning occurred even after 60 minutes. There was little to no peel residue dirt on the support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com