Method for removing ammonia and nitrogen in raw water with powdery zeolite

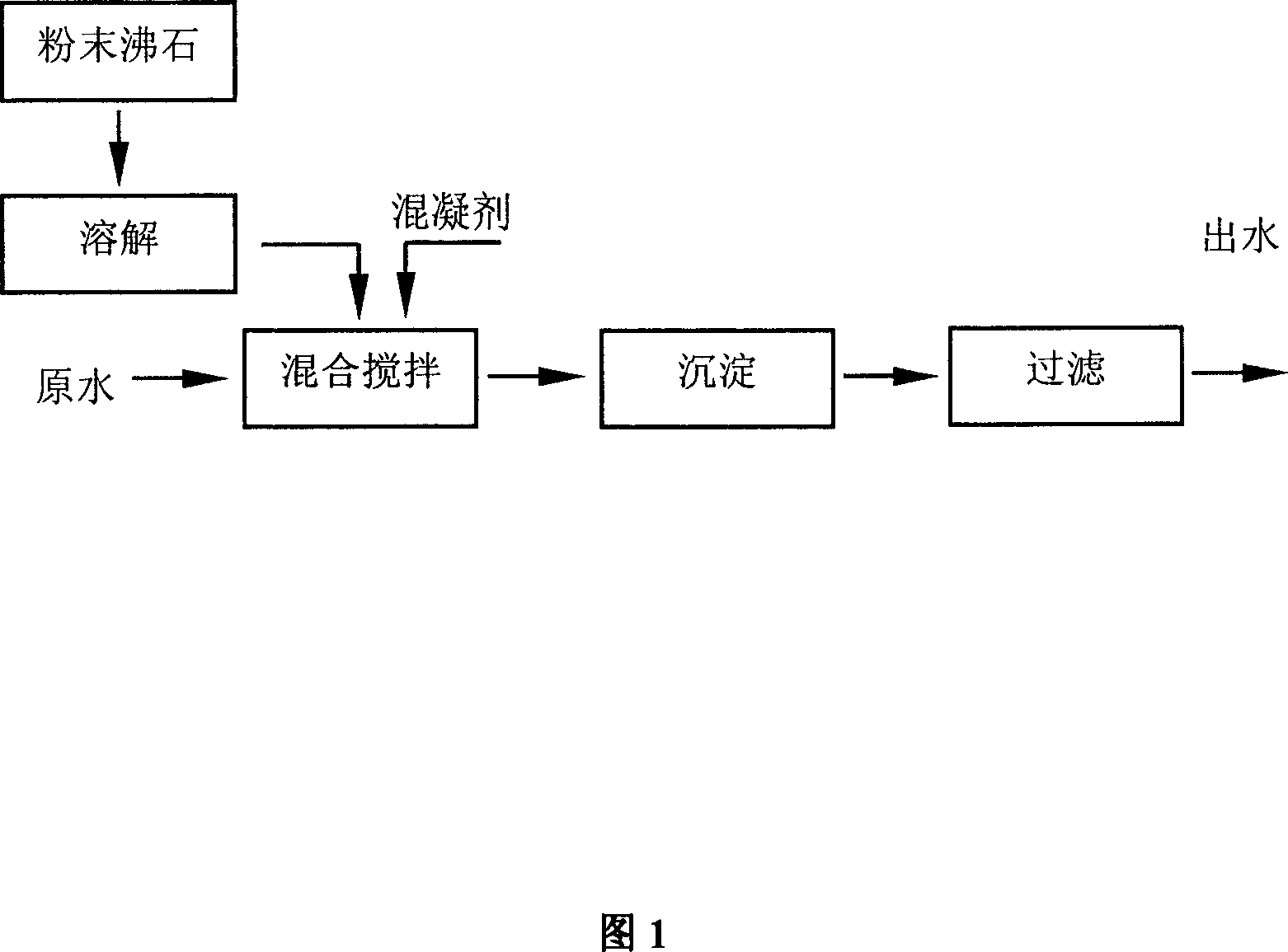

A technology of powdered zeolite and raw water, which is applied in the field of strengthening conventional drinking water treatment technology, can solve the problems of poor removal of ammonia nitrogen, etc., and achieve the effects of reducing effluent turbidity, improving the effect of removing ammonia nitrogen, and promoting coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare the zeolite powder aqueous solution first, adopt the powdered zeolite with an average particle diameter of 14 μm in the table above, and prepare the zeolite powder aqueous solution with a concentration of 2% according to powder zeolite: water=2:100 weight percent. Then pump the prepared zeolite powder aqueous solution into the raw water to be treated with an ammonia nitrogen concentration of 2mg / L and a turbidity of 5NTU in the mixing tank. The dosage is 500mg / L, that is, 500mg per liter of raw water to be treated The zeolite powder aqueous solution made of powdered zeolite is also added with a coagulant (commercially available alum) 30mg / L at the same time, that is, 30mg of alum is added per liter of raw water to be treated, and the adsorption coagulation is completed after mixing and stirring for 10 seconds. Then the raw water that has undergone coagulation and adsorption reaction is pumped into the sedimentation tank for sedimentation, and the residence time i...

Embodiment 2

[0022] When preparing the zeolite powder aqueous solution, the above-mentioned powdered zeolite with an average particle diameter of 10 μm is used to prepare the zeolite powder aqueous solution according to powder zeolite:water=3:100 weight percent. Then add the prepared zeolite powder aqueous solution and coagulant ferric chloride into the raw water to be treated with the ammonia nitrogen concentration of 1mg / L and the turbidity of 10NTU. The dosage is 100mg / L, that is, every liter of raw water to be treated Add 100mg of zeolite powder aqueous solution made of powdered zeolite, and also add 20mg / L of coagulant ferric chloride, that is, add 20mg of ferric chloride per liter of raw water to be treated, and mix for 30 seconds. Then the raw water that has undergone coagulation and adsorption reaction is pumped into the sedimentation tank for sedimentation, and the residence time is 10 minutes. Finally, the effluent from the sand filter with a filtration rate of 10 m / h was tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com