Plate spring skeleton hydrulic pneumatic flexible bending joint

A hydropneumatic and bending joint technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of insufficient sensitivity, inability to achieve multi-joint coordination, and the inability to obtain a more accurate mathematical model for the bending deformation of cylindrical elastic bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

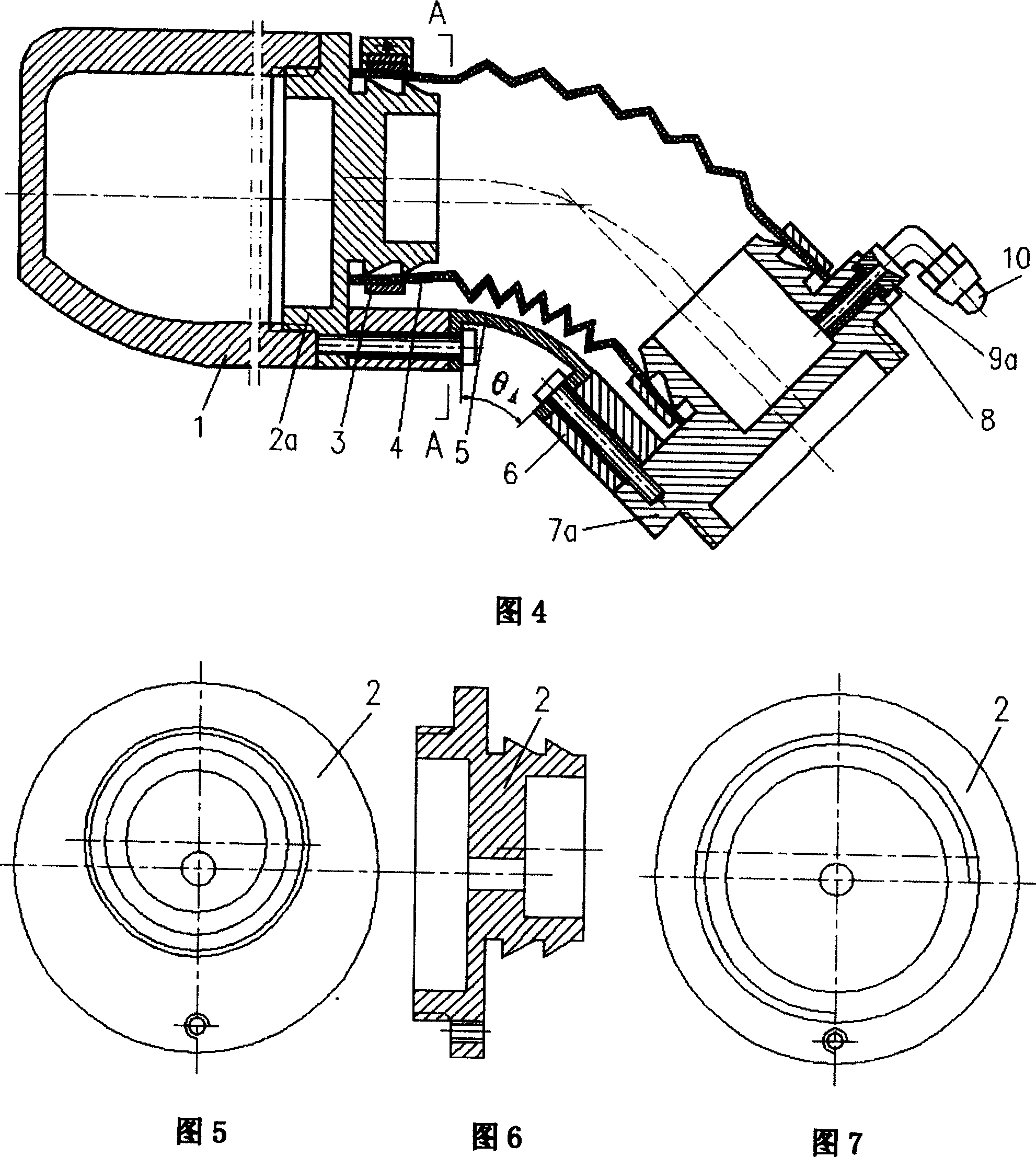

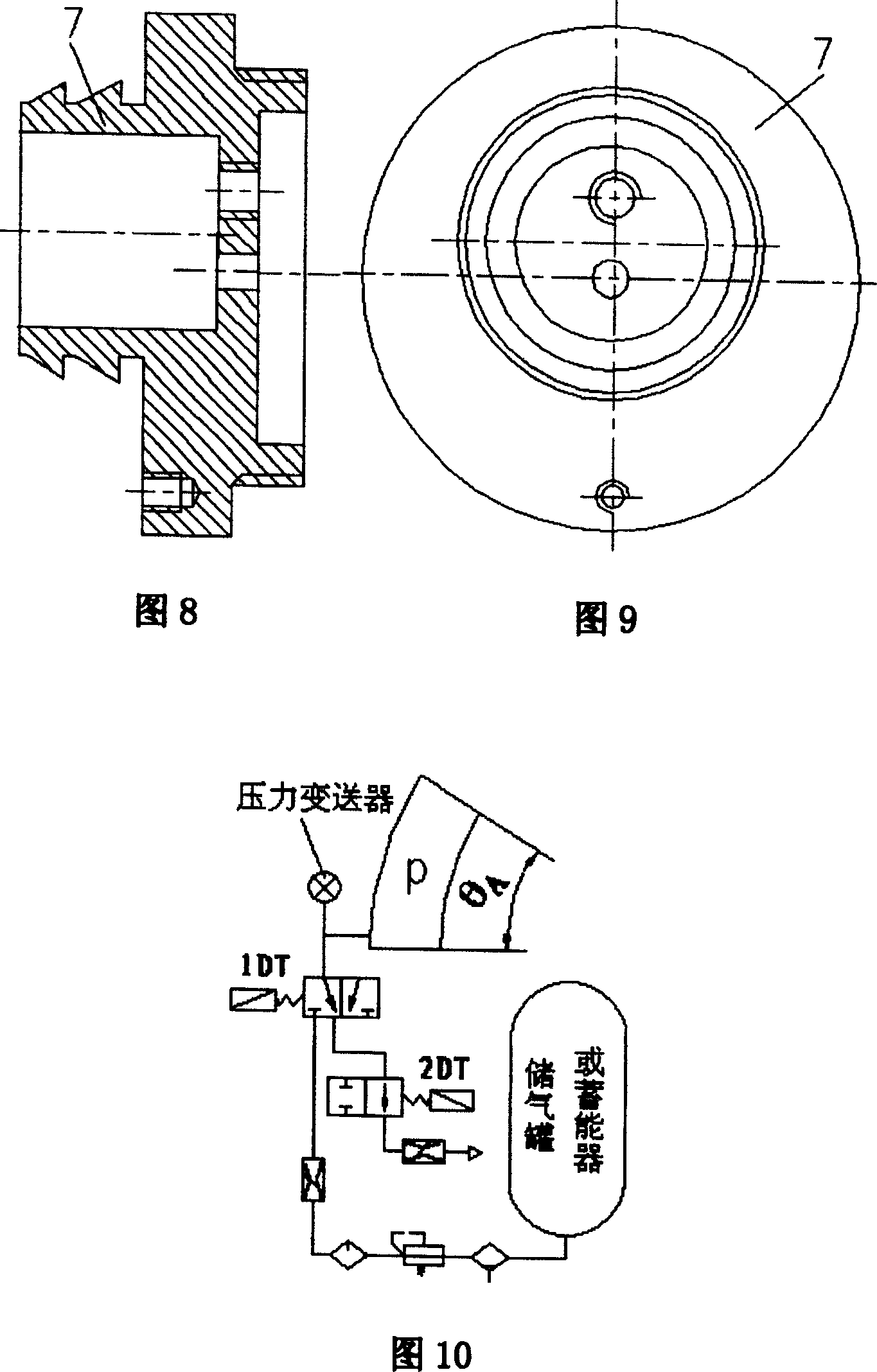

[0020] The present invention will be further described below in conjunction with the implementation of scheme 1 in the accompanying drawings:

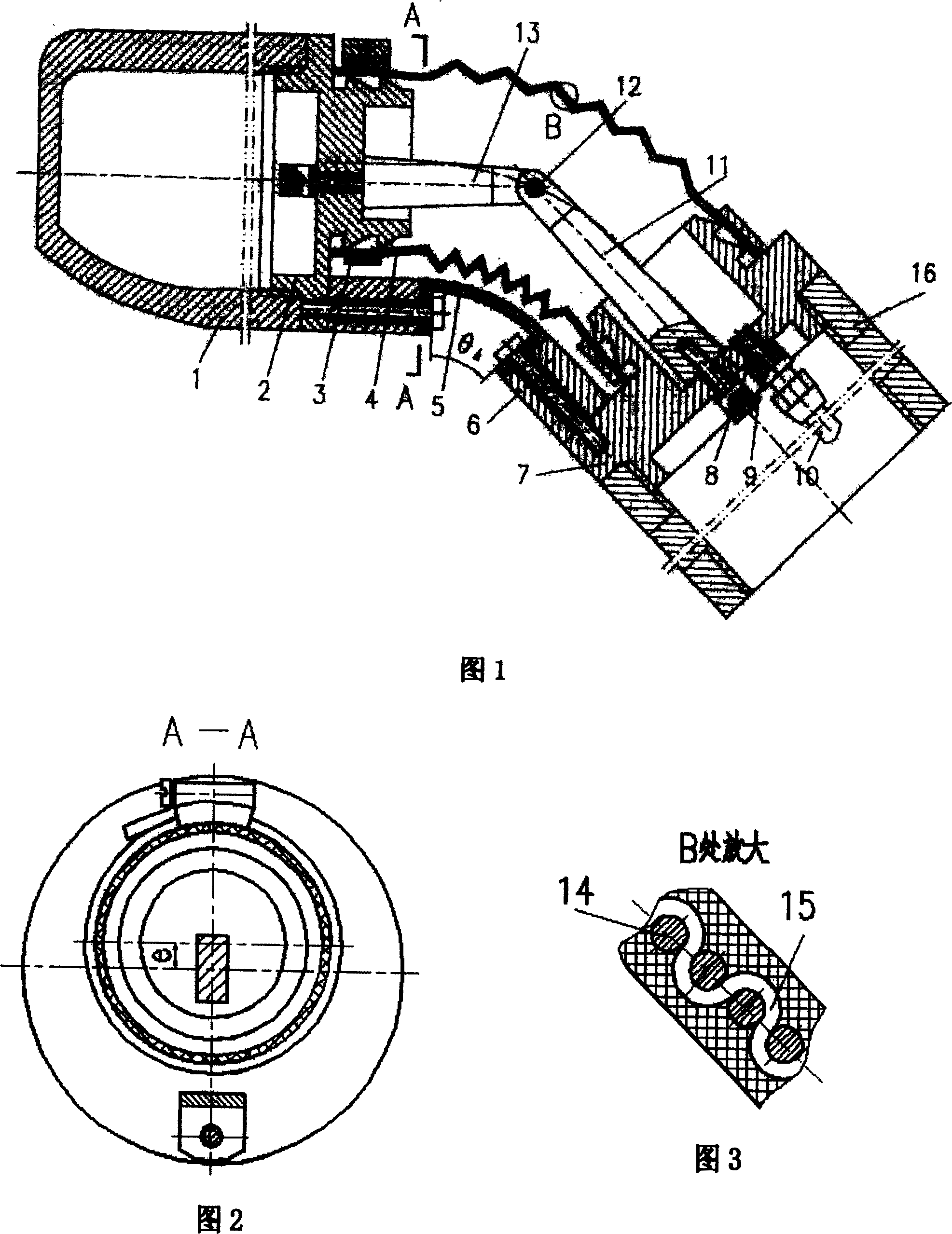

[0021] The joint of scheme I is mainly composed of head section 1, head seat 2, clamp 3, wave shell elastic body 4, leaf spring 5, spacer 6, tailstock 7, gasket 8, pipe joint 9, hose 10, long hinge seat 11. The hinge 12, the short hinge seat 13, the annular weft 14, the winding warp 15, the middle section 16, etc. are constituted.

[0022] The wave shell elastic body 4 is clamped on the bayonet of the headstock 2 and the tailstock 7 by the clamp 3, and the two ends of the leaf spring 5 are fixed on the headstock 2 and the tailstock 7 through the spacer 6; inside the joint, two The inner hexagon bolts pass through the gasket 8 to fix the long hinge seat 11 and the short hinge seat 13 on the tailstock 7 and the head seat 2 respectively. The long hinge seat 11 and the short hinge seat 13 are connected by the hinge 12; The head seat 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com