Paste coating machine and coating method

A coating machine and paste technology, applied in the field of paste coating machine, can solve the problems of increased weight of the door frame, vibration of the device, difficulty in coating the paste pattern, etc., to prevent the reduction of production takt time, The effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings.

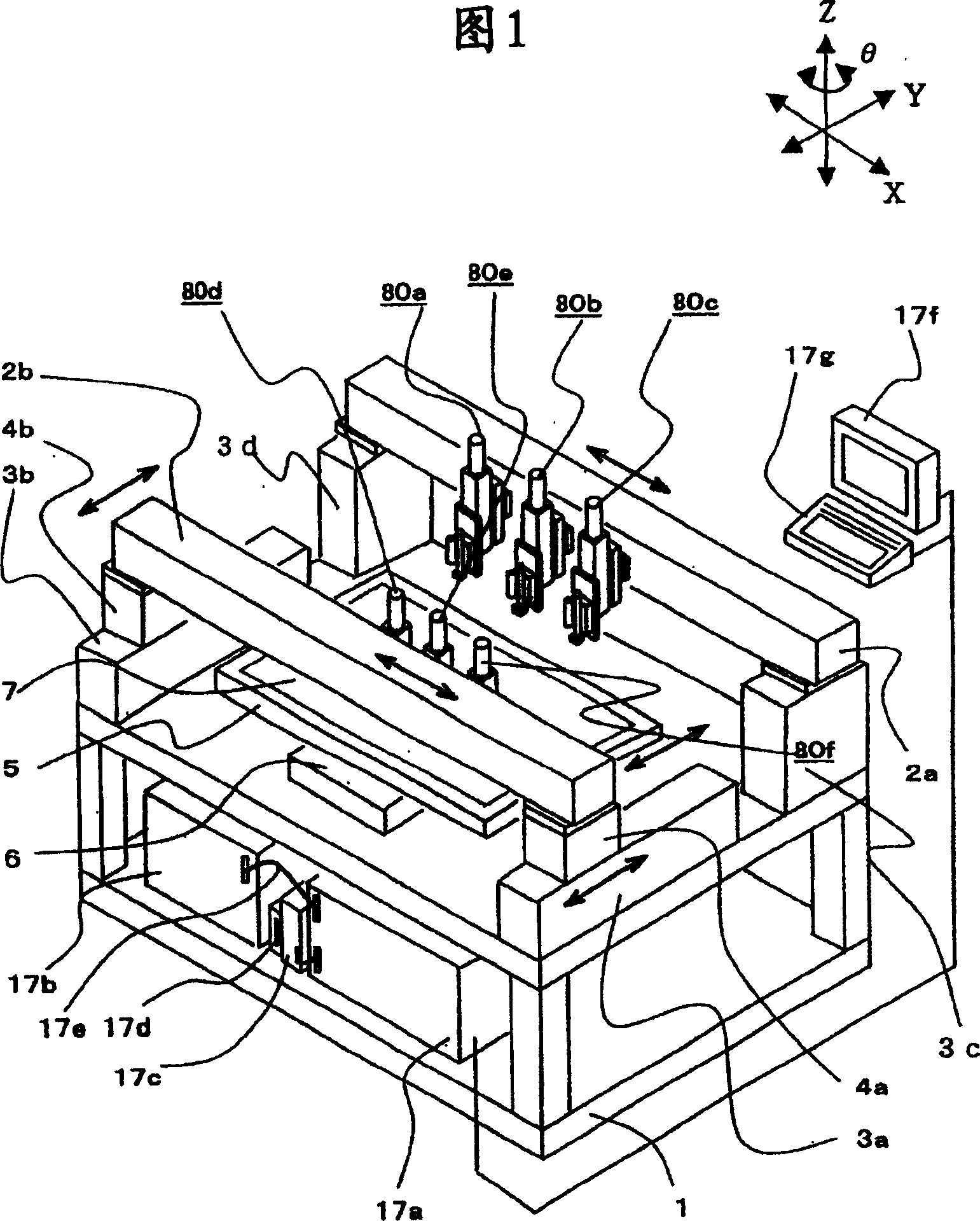

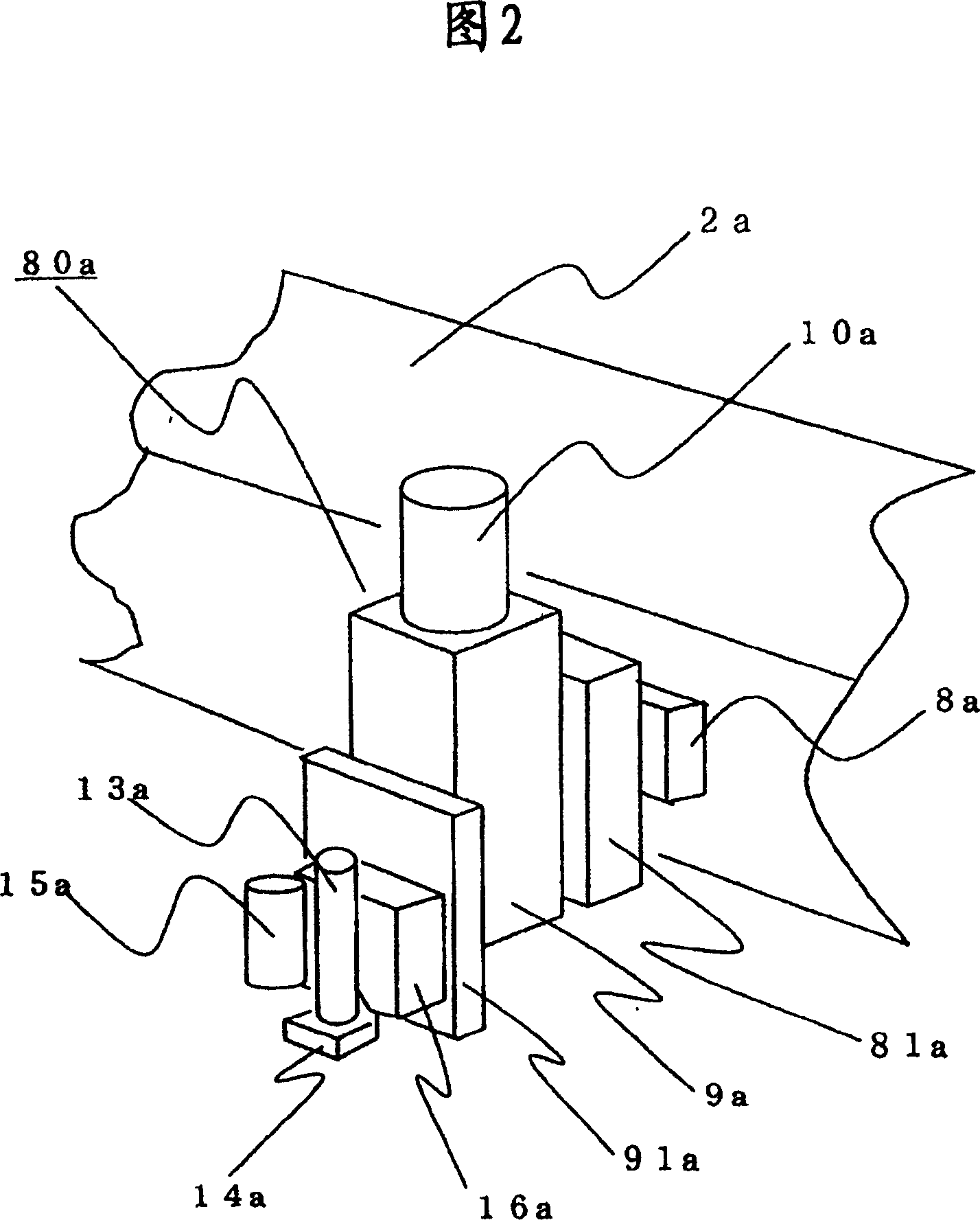

[0020] Fig. 1 is a perspective view showing one embodiment of a paste applicator according to the present invention. FIG. 2 is an enlarged view of the coating head 80a.

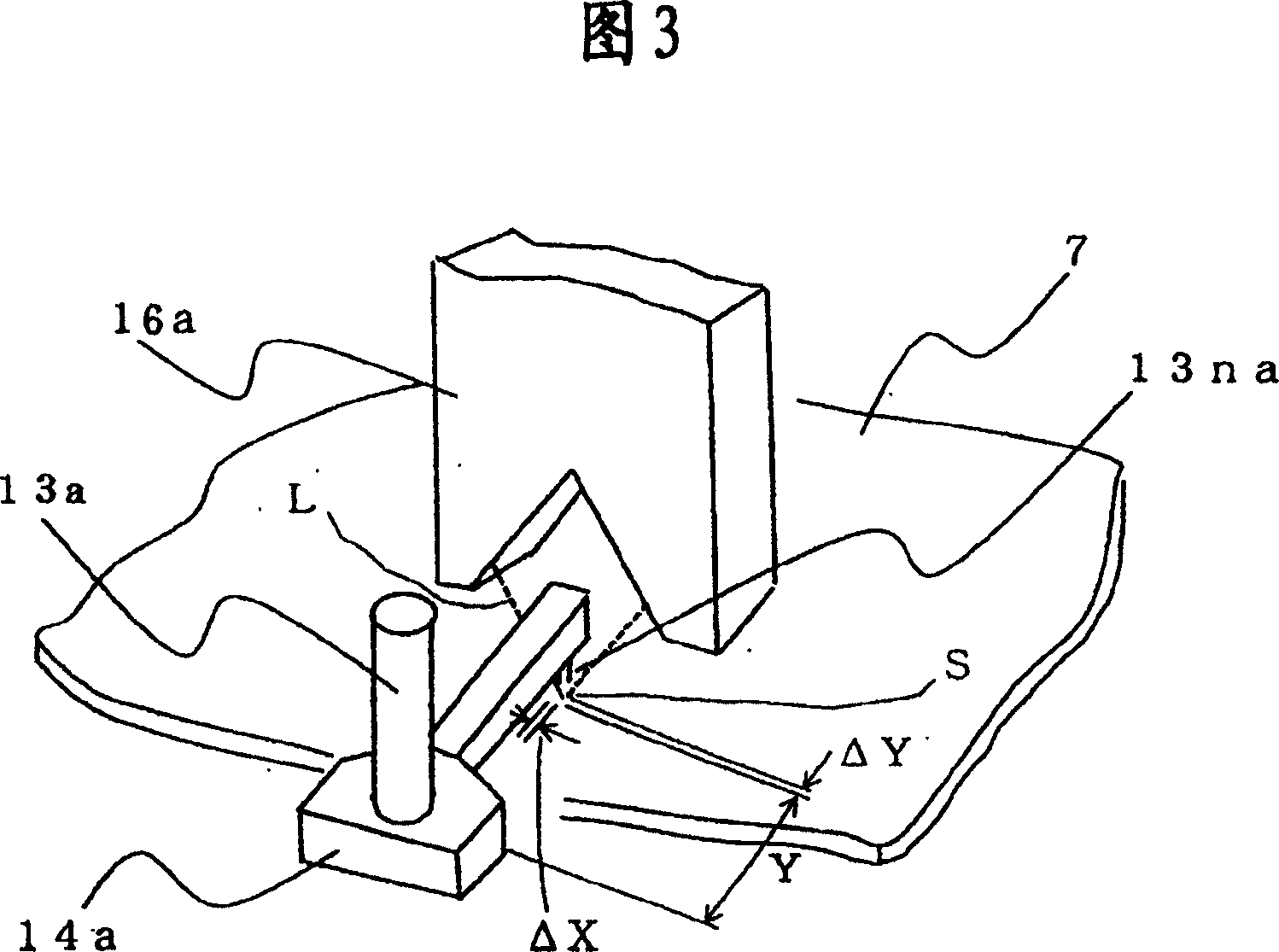

[0021] A plurality of beams 2a, 2b of coating heads 80a to 80f for coating paste are provided facing each other on the bracket 1, wherein one of the beams can change the interval between the brackets in the Y-axis direction. In addition, the beams 2a and 2b are equipped with a coating head X-axis moving mechanism (with the adjustment of the interval in the X-axis direction). That is, although not shown in figure specifically, linear motors 8a-8f are provided for each coating head on beams 2a, 2b so that each coating head can move. In the coating head 80a, as shown in FIG. 2, Z-axis moving table support brackets 81a-81f are provided on the linear motors 8a-8f. Z-axis moving tables 9a-9f and Z-axis servomoto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com