Multicutter technique for cutting inner circle and device

A multi-knife cutting and inner circle slicing technology, which is applied in the direction of shearing device, sawing device, manufacturing tools, etc., can solve the problem of high processing equipment and environmental conditions, high processing precision requirements, and low efficiency of single blade inner circle slicer And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

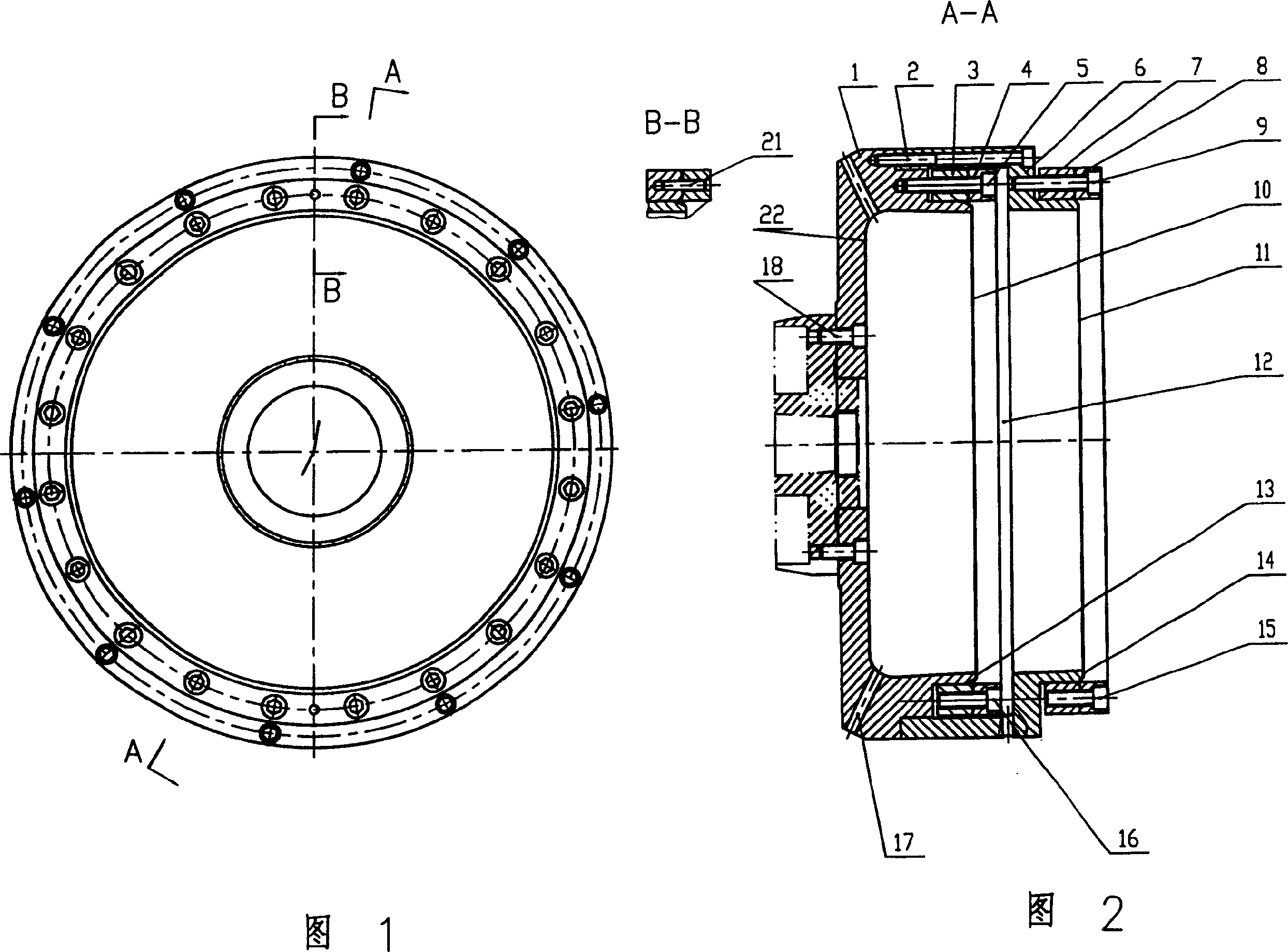

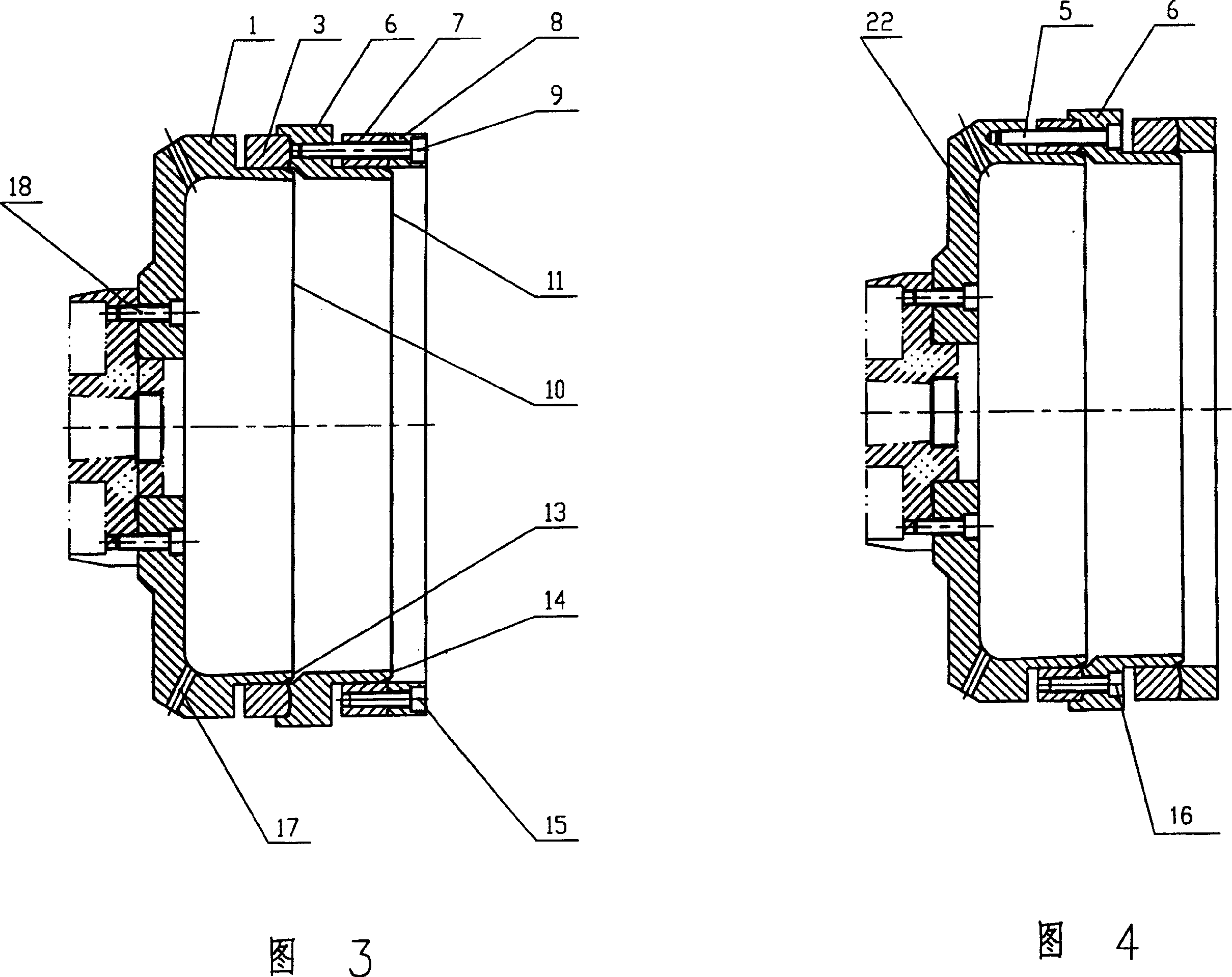

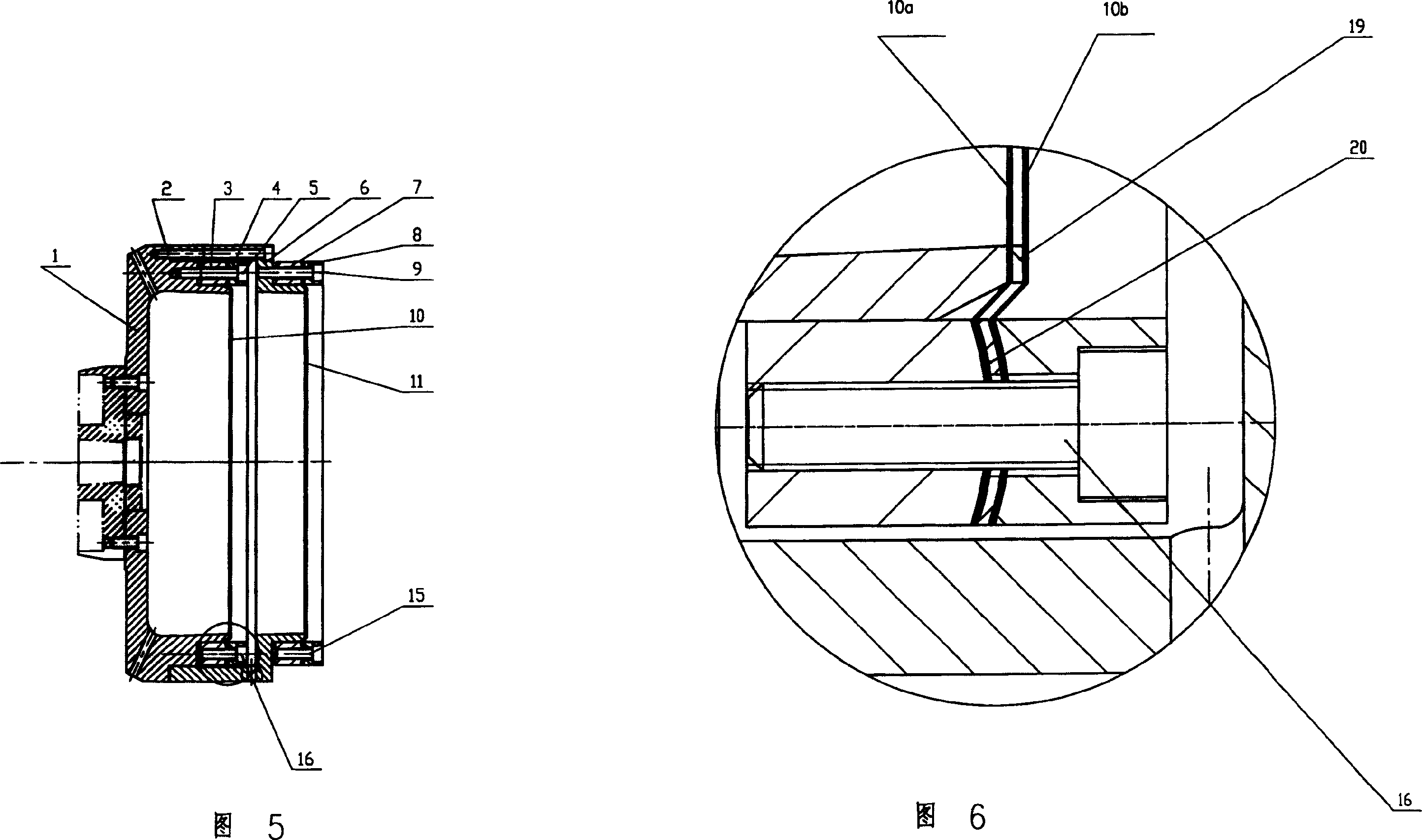

[0017] As shown in Fig. 2, Fig. 3 and Fig. 5, the cutter assembly of the multi-knife internal circle slicer is fitted with an intermediate ring 6 on the outer surface of the cutter disc 1. The large end surface of one end of the intermediate ring is covered outside, and the other end is a small end surface. Be enclosed within the inside of outer left knife holder ring 7. Between the cutter head 1 and the middle ring 6, an inner left cutter ring 3 and an inner right cutter ring 4 are set to clamp and fasten the first inner circle slicer, and the blade tension is adjusted by the inner cutter ring screw 5 And fasten it with the cutter head. After loading onto the middle ring 6, the middle ring 6 is fixed with the dress cutter head by the fastening screw 2 of the middle ring of the cutter head. The second inner circle slicing knife is installed between the outer left clamping ring 7 and the outer right clamping ring 8 and is tensioned by the small end face of the middle ring 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com