Electrical insulating resin material, electrical insulating material, and electric wire and cable using same

A technology of electrical insulating materials and resin materials, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as insufficient product dispersion, melt fracture, and reduced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

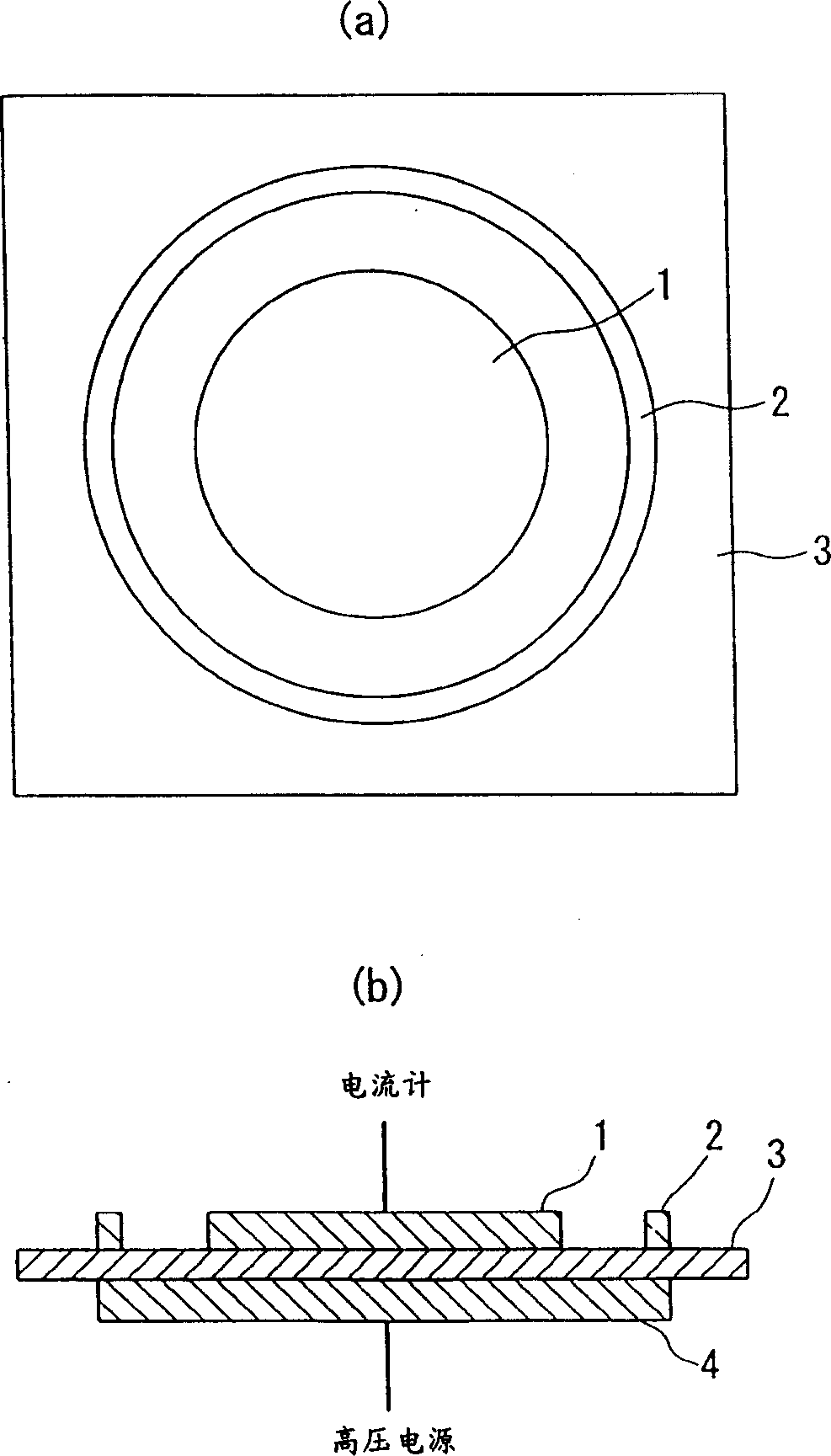

Image

Examples

example 1

[0232] A graft copolymer (C11) obtained by modifying an ethylene copolymer (A) with a functional group-containing monomer (M1). Specific examples thereof include maleic anhydride-modified ethylene copolymers (A).

example 2

[0233] Ethylene copolymer (A) and graft copolymer (C11) obtained by modifying ethylene copolymer (A) with functional group-containing monomer (M1), and / or using functional group-containing monomer (M1) A composition of a graft copolymer (C21) obtained by modifying another polyolefin (A'). Specific examples thereof include compositions of ethylene copolymer (A); maleic anhydride-modified ethylene copolymer (A), and / or maleic anhydride-modified low-density polyethylene.

[0234] A composition of another polyolefin (A') and a graft copolymer (C11) obtained by modifying an ethylene copolymer (A) with a functional group-containing monomer (M1). Specific examples thereof include compositions of low-density polyethylene and maleic anhydride-modified ethylene copolymer (A).

example 4

[0235] Ethylene copolymer (A) and other polyolefins (A'); and graft copolymer (C11) obtained by modifying ethylene copolymer (A) with functional group-containing monomer (M1) , and / or a composition of a graft copolymer (C21) obtained by modifying other polyolefin (A') with a functional group-containing monomer (M1). Specific examples thereof include ethylene copolymer (A); low-density polyethylene; maleic anhydride-modified ethylene copolymer (A), and / or compositions of maleic anhydride-modified low-density polyethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com