Pipe-cutting machine and cutting method

A cutting machine and pipe technology, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of pipe mouth deformation, poor finish, unusable, etc., and achieve the effect of novel structure design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

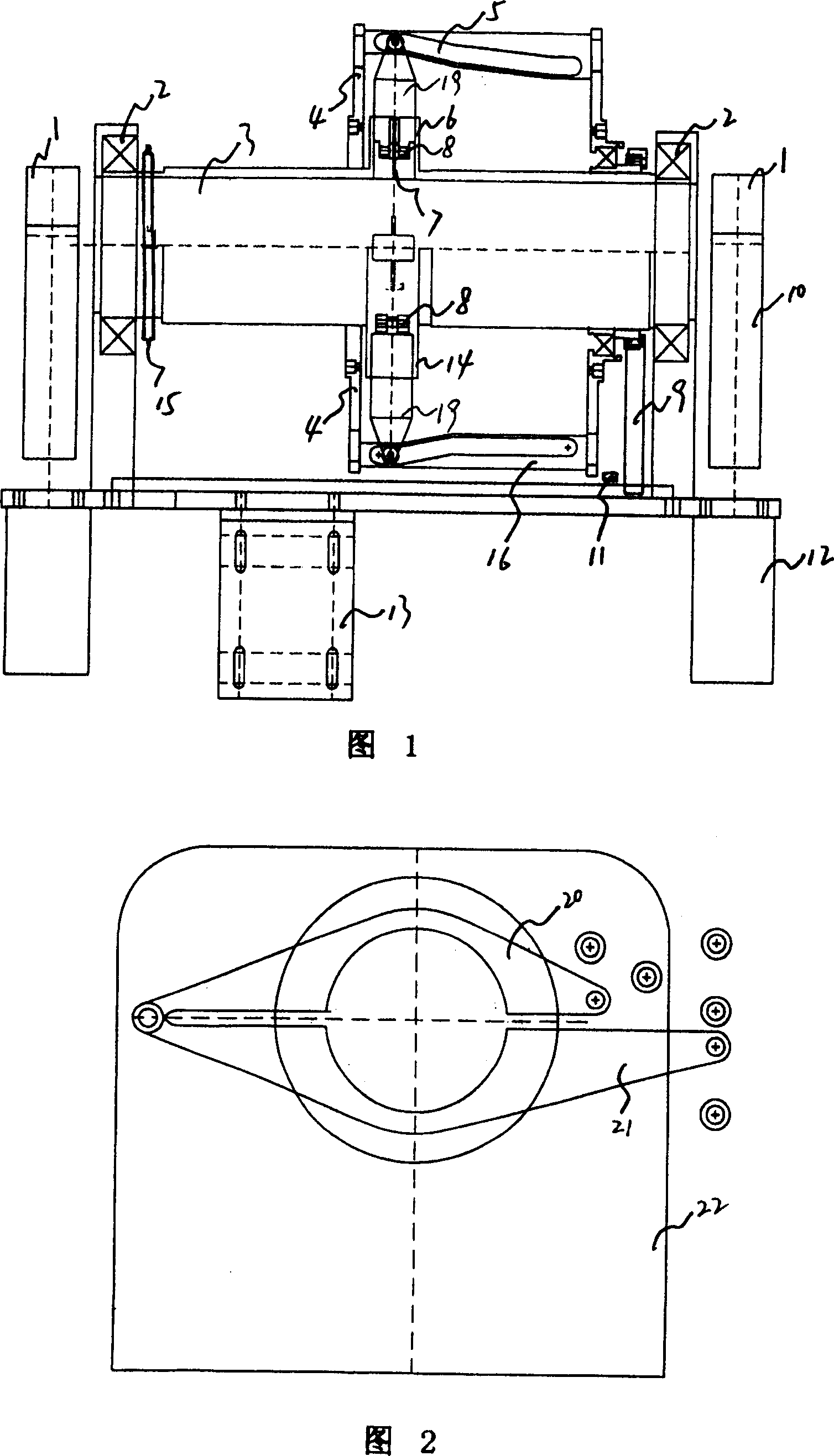

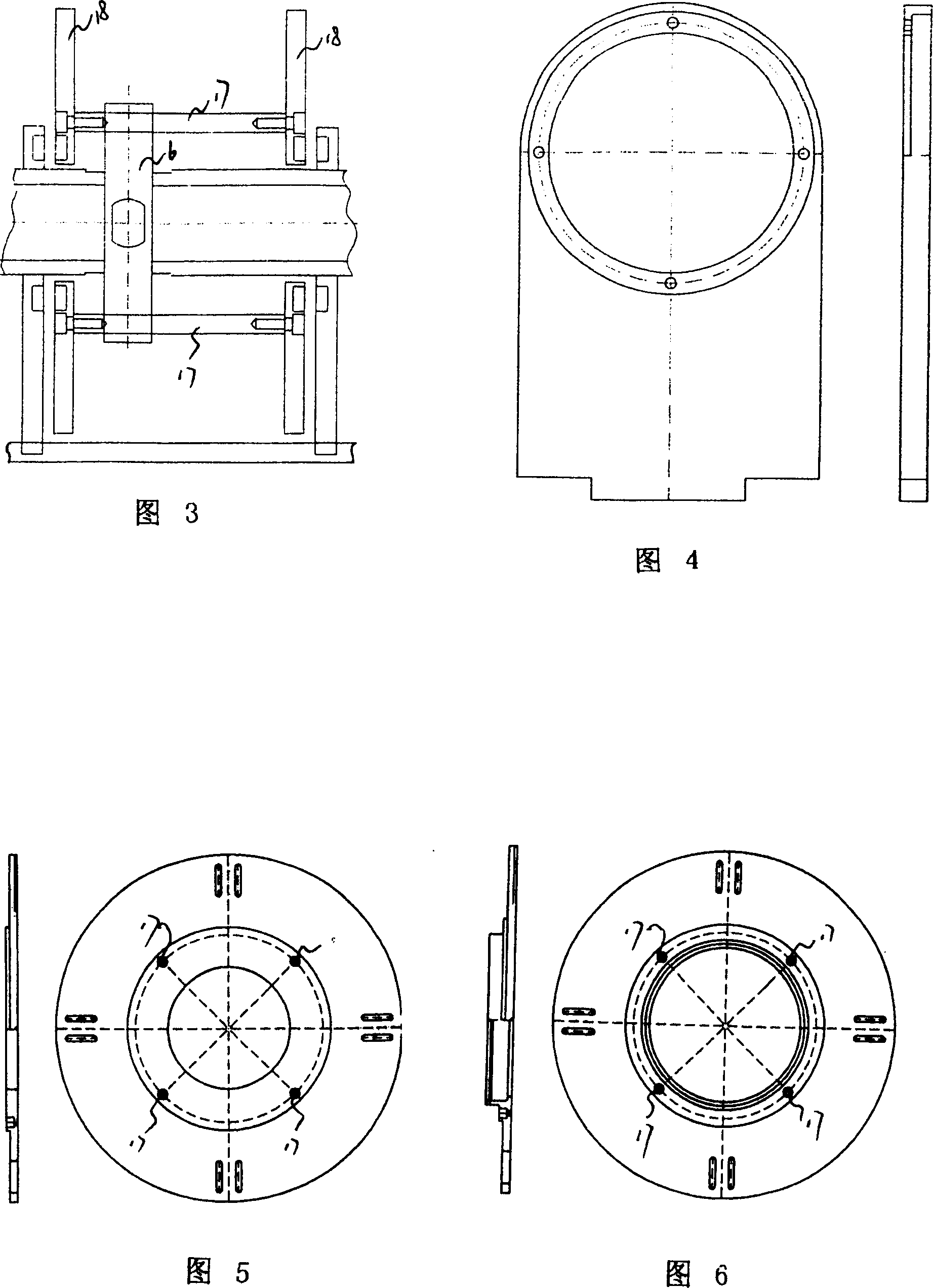

[0014] Embodiment 1: with reference to accompanying drawing 1~6. Pipe cutting machine, the two ends of the main shaft 3 with threaded thread are positioned on the frame through the bearing 2, the main shaft 3 is a hollow main shaft, and threaded thread or part of threaded thread is formed on it. The opposite place between the main shaft 3 and the blade 7 has a blade inlet. The two clamping devices 1 are respectively located on the racks at both ends of the main shaft and driven by the cylinder 12 to clamp or loosen the clamping devices. The clamping device 1 is composed of an arc-shaped upper splint 17, an arc-shaped lower splint 18 and a bracket 19. One end of the upper splint 17 and the arc-shaped lower splint 18 are hinged and positioned on the support 19, the other end of the arc-shaped upper splint is fixed on the frame, and the other end of the arc-shaped lower splint is connected with the cylinder 12 through the connecting rod 10 (see accompanying drawing 1 and 2). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com