Method of forming sub-micron-size structures over a substrate

A sub-micron and substrate technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of lack of nucleation position arrangement and arrangement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

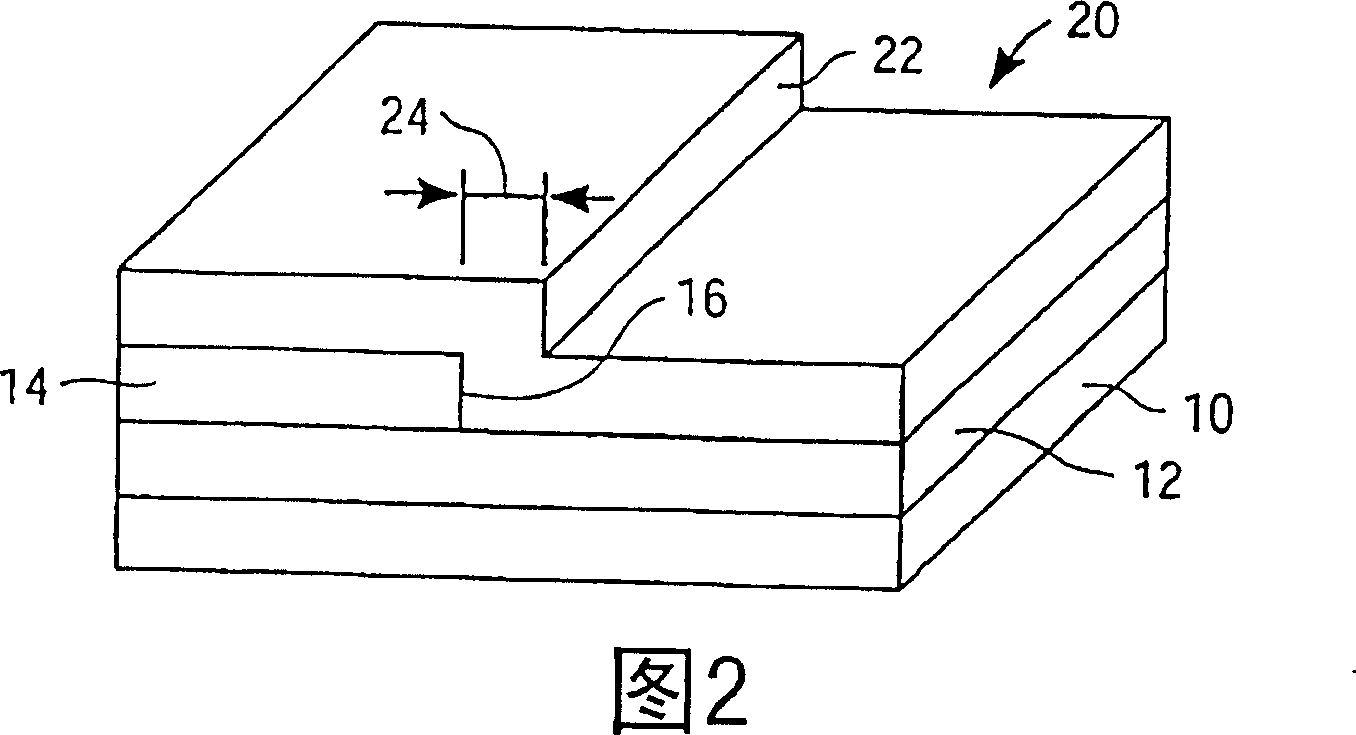

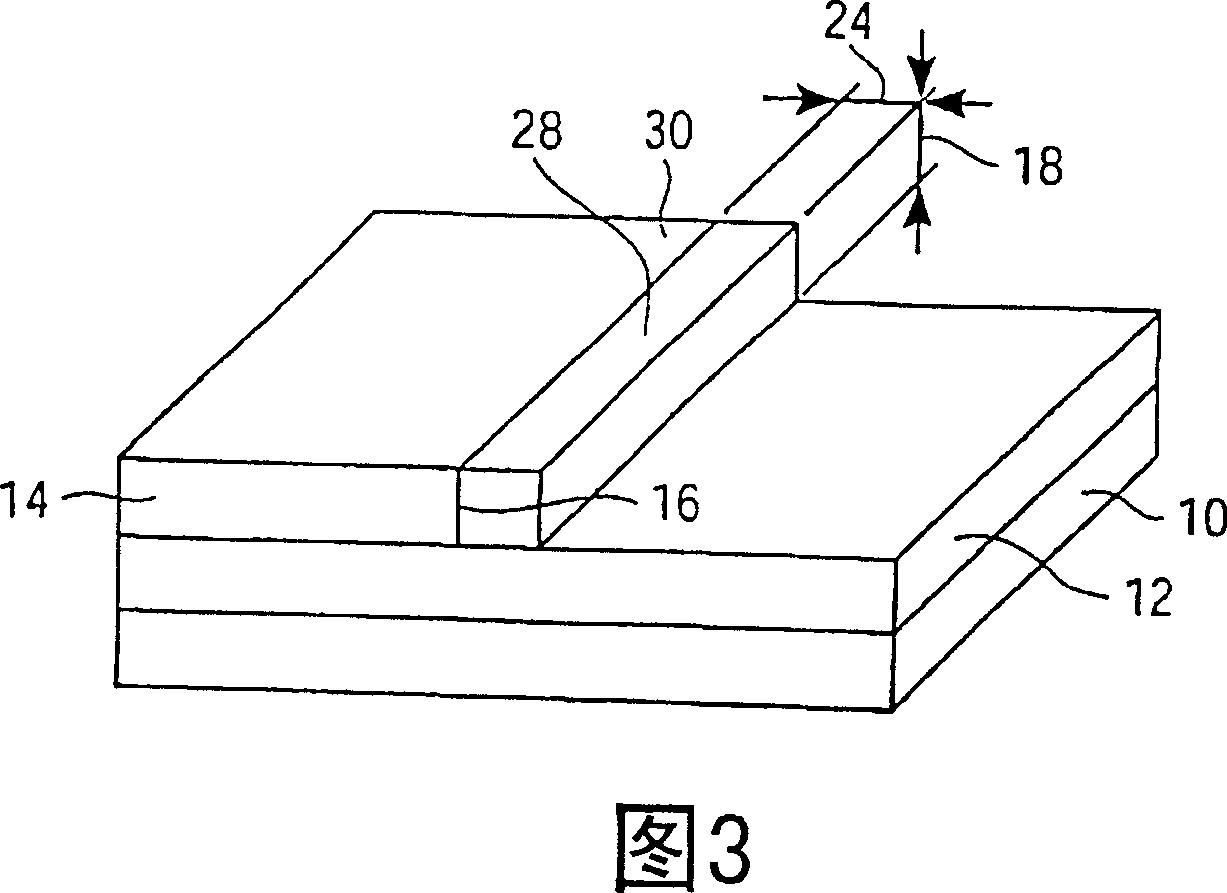

[0023] A method for forming submicron sized structures on a substrate is provided. A width-defining step is formed on the substrate. A width-defining layer is formed on an edge of the width-defining step. The width-defining layer is etched back to leave a spacer adjacent to the width-defining step. A length-defining step is formed on the substrate. A length-defining layer is formed on the edge of the length-defining step. The length-defining layer is etched back to leave a spacer proximate to the first edge of the length-defining step and spanning a first portion of the spacer left by the width-defining layer. Then remove the length-defining step. The spacers left by the width-defining layer are then etched using the spacers left by the length-defining layer as a mask to form the structure.

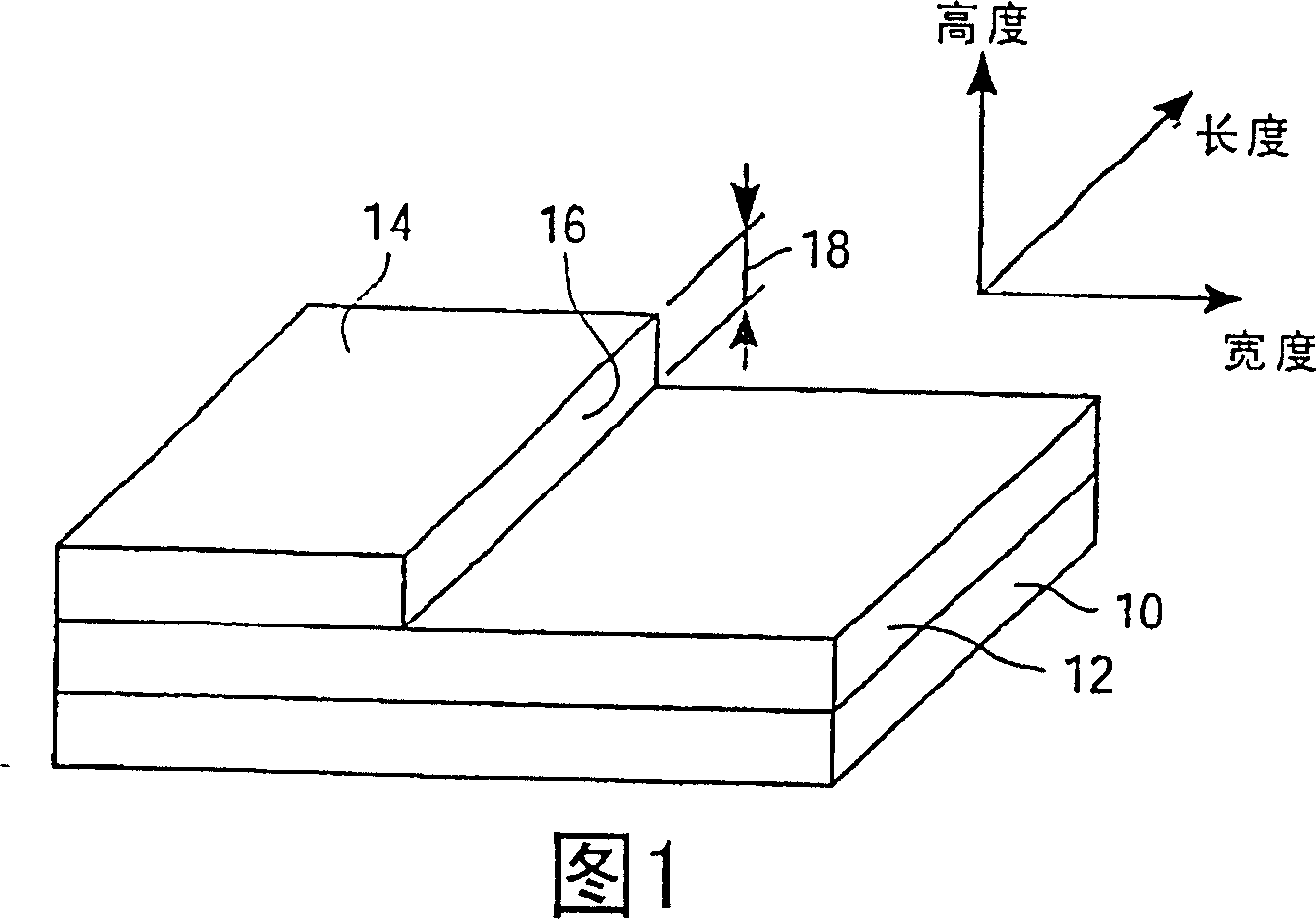

[0024] Figure 1 illustrates an initial process for forming a structure according to an embodiment of the invention. A substrate 10 is provided, and an insulating layer 12 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com