Field emission device and a method of forming such a device

A field emission and emission device technology, which is applied in the direction of electrical components, the manufacture of discharge tubes/lamps, and parts of discharge tubes/lamps, etc. Waste of time and other problems, to achieve the effect of reducing the number of steps, improving control, and easy conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

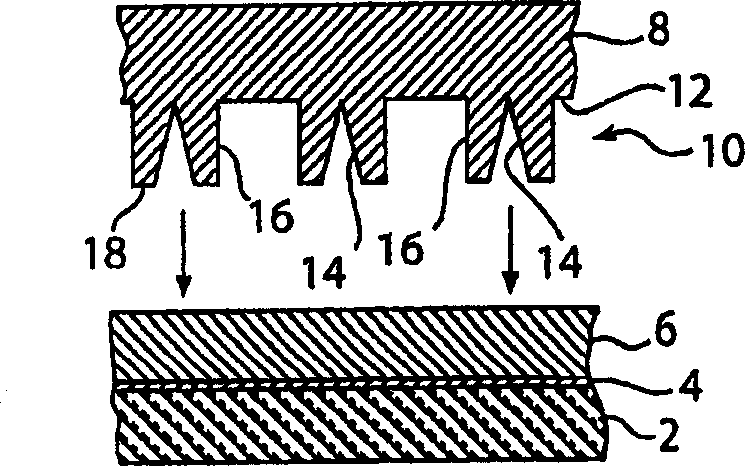

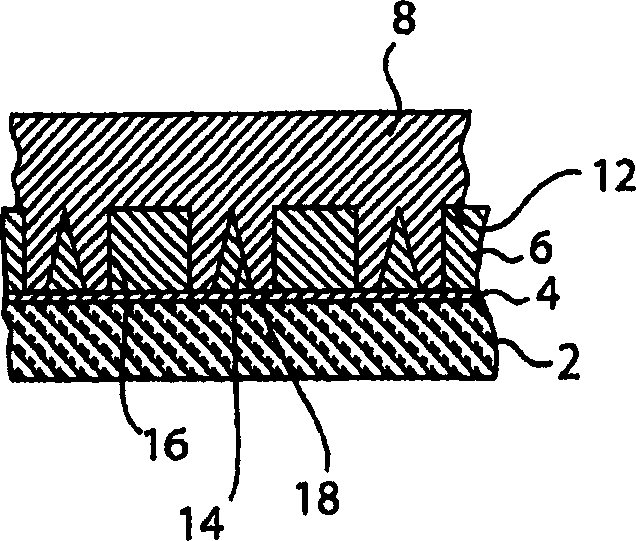

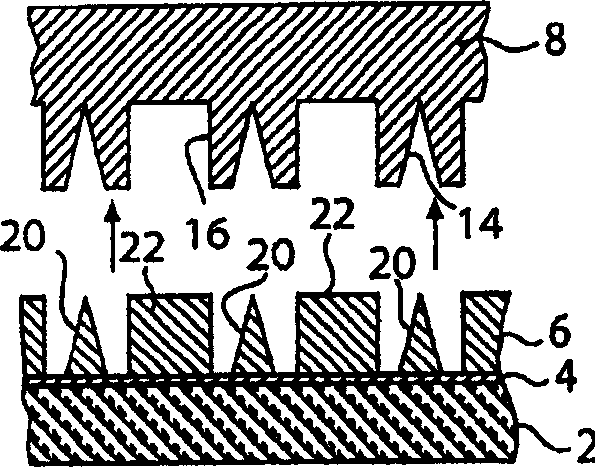

[0037] A gate structure (triode structure) for a field emission device is produced by means of an embodiment of the method according to the invention. In FIG. 1, the manufacture of a field emission device 1 having a triode structure is described.

[0038] A substrate 2 , for example a glass plate, firstly has an electrically conductive layer in the form of a patterned cathode 4 . The cathode 4 will form the first electrode in the triode structure. Such as Figure 1A As shown, a layer 6 of liquid material is disposed over the substrate 2 and the cathode 4 . Layer 6 preferably has a thickness between 1 and 10 micrometers and is deposited on substrate 2 by means of spin-coating processes, screen-printing techniques or dip-coating processes among others. The liquid material is preferably of the sol-gel type, such as suspensions of silica gel (Silica Sol TM50) and methyltrimethoxysilane (MTMS). Alternatively, the liquid material comprises polyimide with a photosensitive compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com