Method for producing liquid-phase solid film of film filtering tank for sewage treatment

A technology of sewage treatment and manufacturing method, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc. The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

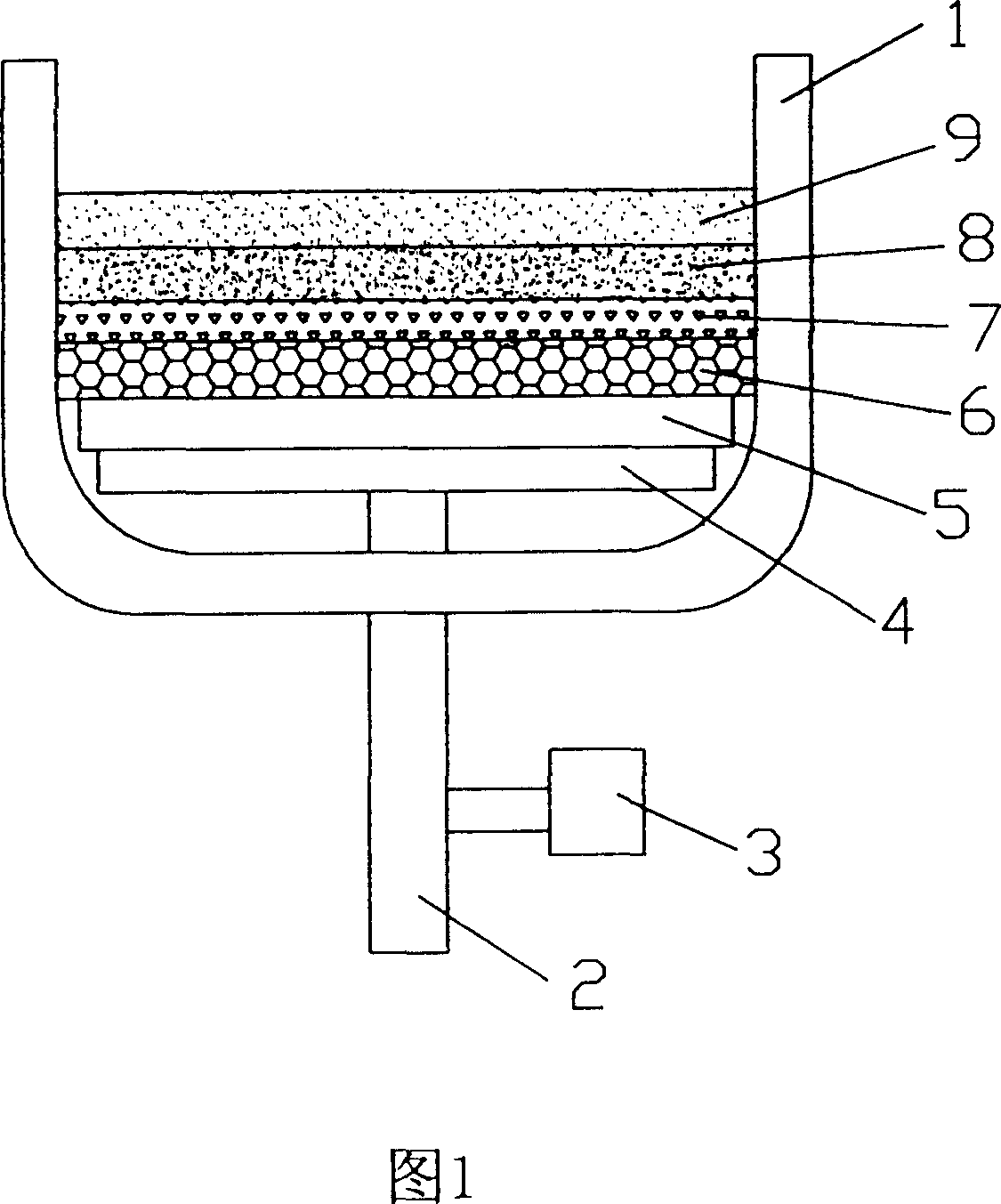

[0014] Please refer to the manufacturing device of the liquid-phase solid-state membrane of the membrane filter of Fig. 1 sewage treatment, the area of liquid-phase solid-state membrane filter 1 is 50m 2 ~300m 2 , the material is steel concrete frame, and the height of the vacuum chamber in the pool is greater than 60 cm.

[0015] The bottom of the pool is close to one end, passing through the bottom of the pool and vertically connected to the bottom of the pool with an airtight and watertight vertical steel pipe 2, parallel to the bottom of the liquid phase solid membrane filter 1 is a horizontal steel pipe 4, the vertical steel pipe 2 is connected with the horizontal steel pipe 4, There is a water pump 3 outside the pool, and the vertical steel pipe 2 is connected with the water pump 3 .

[0016] Arranged upwards at the bottom of the pool are: pipes 5 made of cement flower pipes, cobblestones 6 , stones 7 , sand 8 and liquid-phase solid film 9 for paving the pipes 5 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com