Centrifugal method and apparatus for devolatilizing polymers

A technology for devolatilization and polymers, which is applied to remove volatile substances in thermoplastic polymers. From the thermoplastic field, it can solve the problems of unable to produce spherical devolatilization polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

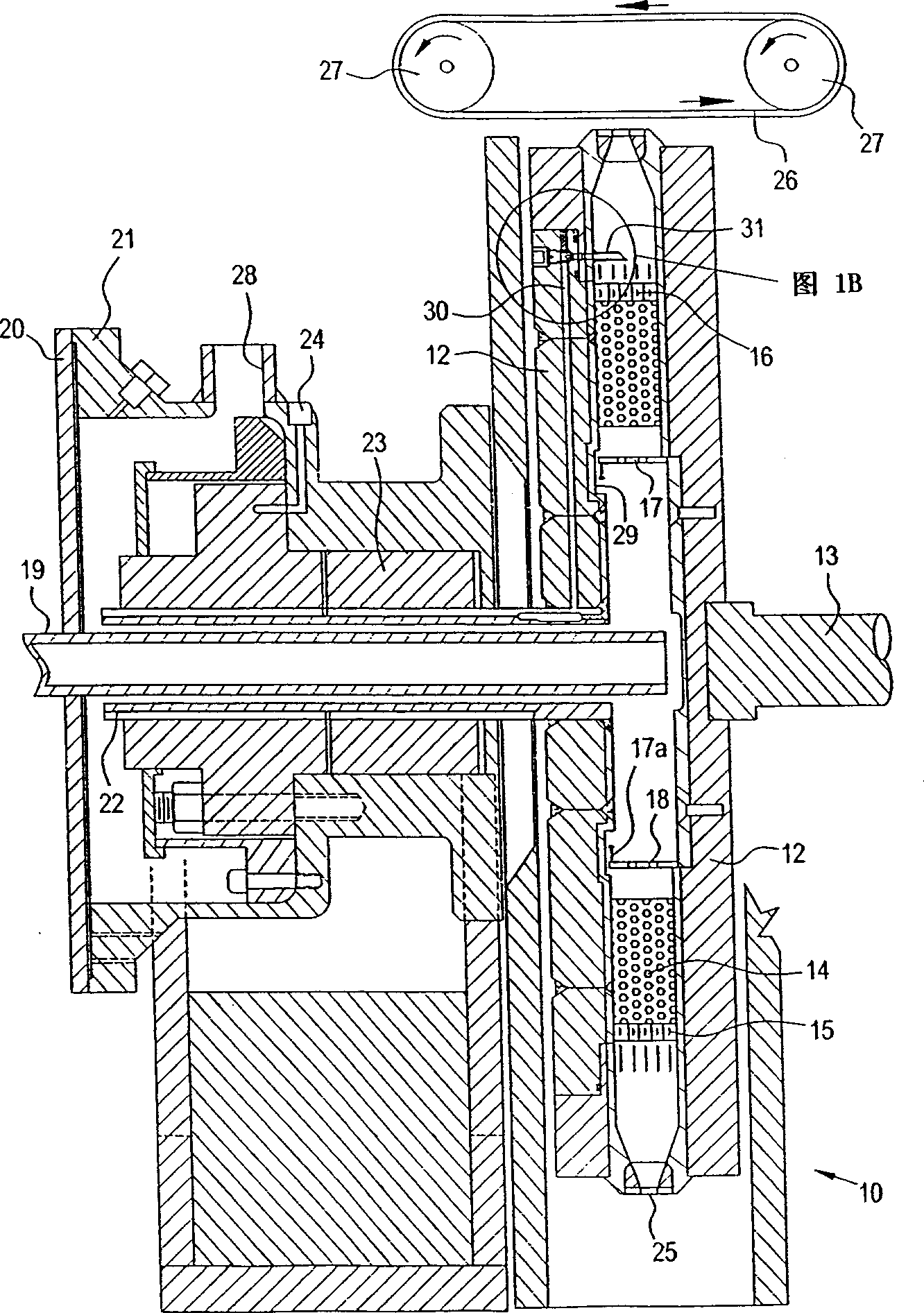

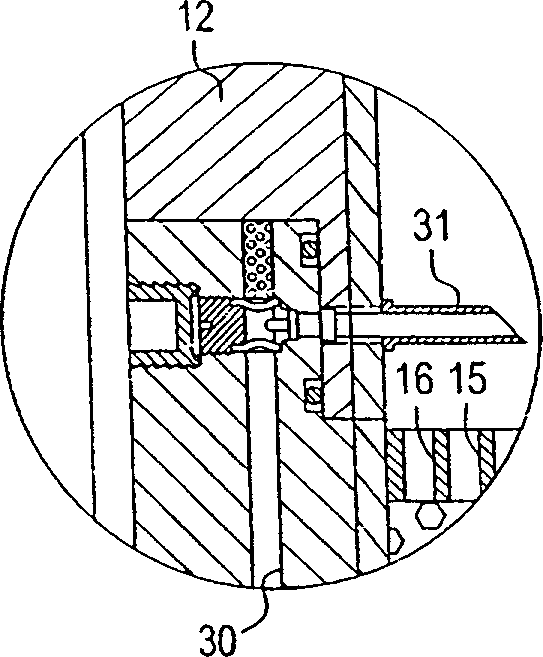

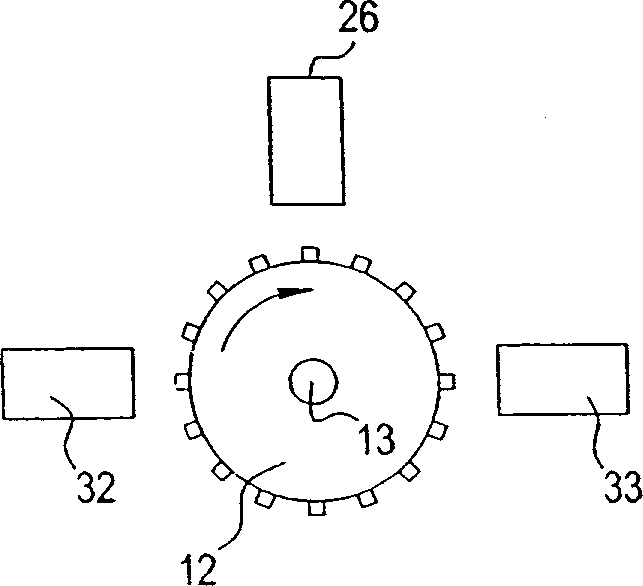

[0008] Referring now to FIG. 1, there is shown a side cross-sectional view of an embodiment of an apparatus 10 of the present invention. The device 10 comprises a disc-shaped chamber 12 which rotates by means of a shaft 13 about the longitudinal axis of said shaft 13 . The shaft 13 is driven to rotate by a motor (not shown). The chamber 12 comprises an annular ring of nickel-chromium metal open cell foam packing 14 cut from a large workpiece of material, preferably by an electrode discharge machining process. The filler 14 is Celmet Brand #1 material available from Sumitomo Electric USA, NY, NY. An annular support belt 15 surrounds said packing 14 . The support strip 15 is perforated with holes 16 . An annular distribution belt 17 is placed inside said packing 14 . The dispensing strip 17 is perforated with holes 18 .

[0009] A polymer conduit 19 extends into chamber 12 and terminates in the chamber. The polymer conduit 19 includes a flange 20 and a sealing mounting bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap