Flexible polyurethane material

A polyurethane and polyester technology, applied in the field of flexible polyurethane materials, can solve the problems of degradation, yellowing, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

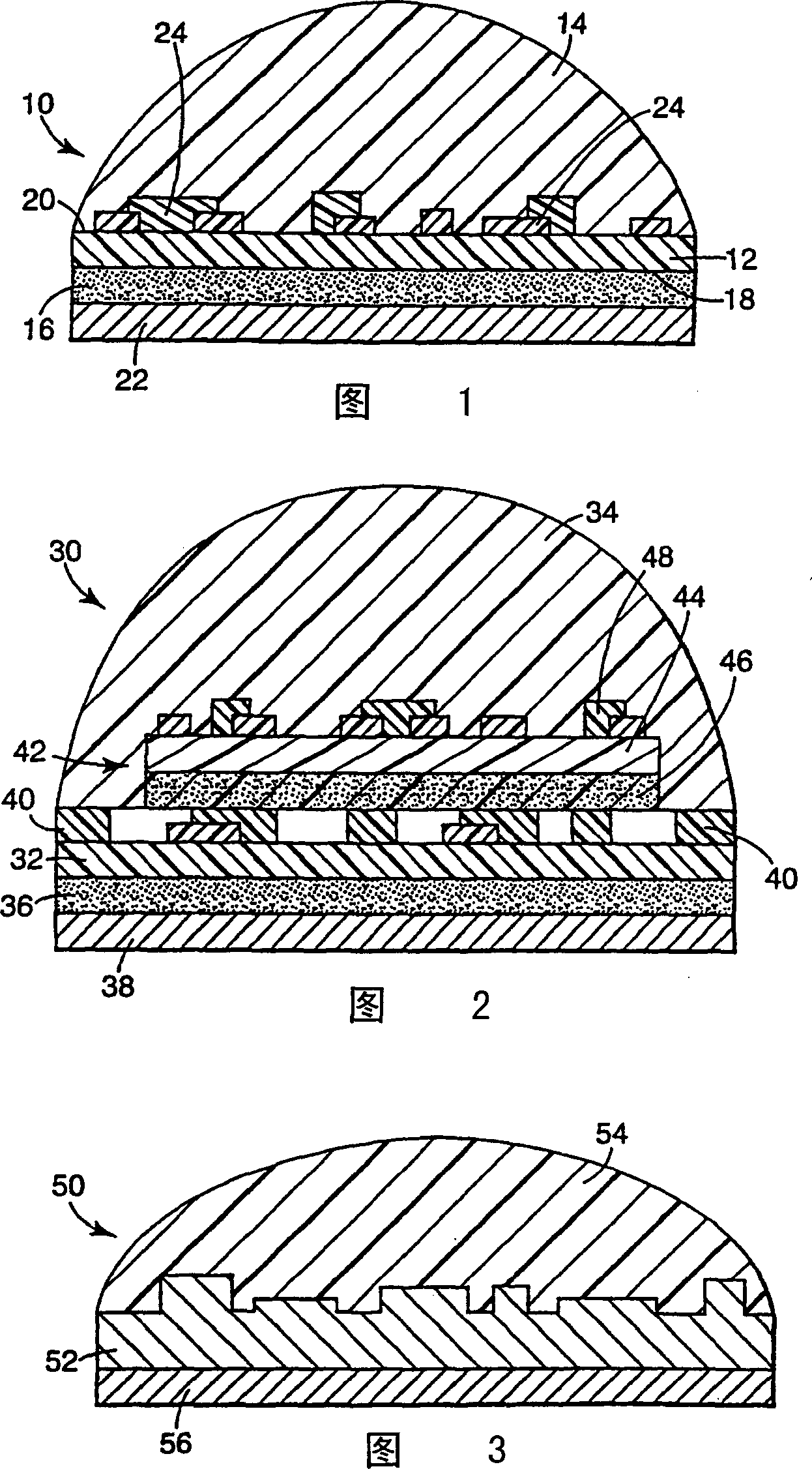

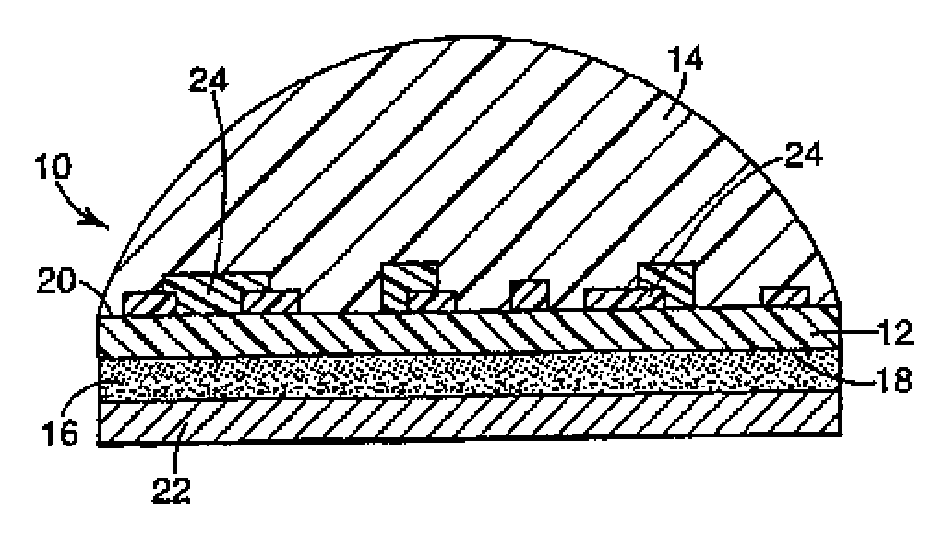

Image

Examples

Embodiment 1

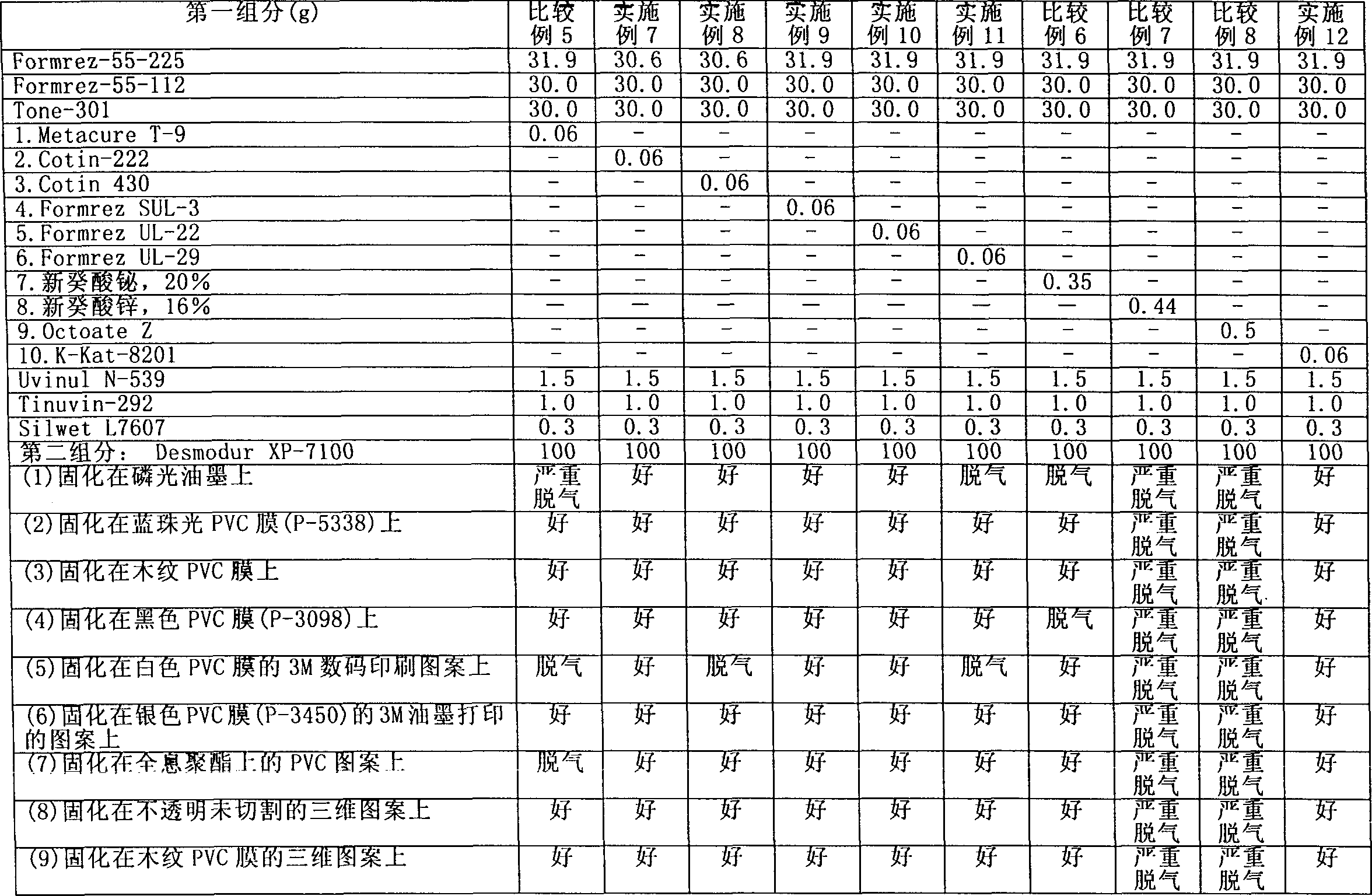

[0068] The polyester polyol / diol-based first component was prepared as follows: 31.9 g Formrez-55-225, 30 g Formrez-55-112, and 30 g Tone-301 were mixed together in a round bottom flask and heated to 70°C. The mixture was stirred and degassed under vacuum (approximately less than 30 inches of mercury) for 4 hours until no bubbles escaped. The temperature of the mixture was cooled to about 50°C and 0.06 g T-12, 0.2 g Silwet L-7607, 1.5 g Uvinul N-539, and 1 g Tinuvin-292 were added to the mixture. The mixture was stirred for 15 minutes. The formula (weight percentage) of the first reaction component is listed in Table 2.

[0069] The second reaction component includes 100 g of polyisocyanate (Desmodur XP-7100). The first and second reaction components were mixed together in a volume ratio of 1:1 and poured on the 11 substrates. The polyurethane was cured in a convection oven at 52°C for 10 hours. The cured polyurethane has no outgassing phenomenon on all substrates, and has excelle...

Embodiment 2-6

[0075] The first component used in Examples 2-6 was prepared in the same manner as in Example 1. The composition of the first component of each example is listed in Table 1.

[0076] The second component used in Example 2 was prepared by reacting 30g Pluracol-538 and 70g Vestanat IPDI at 80°C for 4 hours. The second component formed includes a mixture of polyisocyanate with primary and secondary isocyanate groups and monomer Vestanat IPDI. The second component used in Example 3 was the same as that used in Comparative Example 1. The second component used in Example 3 includes a mixture of secondary polyisocyanate and the monomer Desmodur W. The second component used in Example 4 was prepared by mixing 70 g of polyisocyanate and 30 g of Desmodur H. The second component used in Example 5 was prepared by mixing 50 g of polyisocyanate and 50 g of Desmodur H.

[0077] The first and second components were mixed together in a volume ratio of 1:1 to prepare polyurethane and poured on the ...

Embodiment 13-18

[0082] The first component used in Examples 13-17 was prepared in the same manner as in Example 1. Different components are used to illustrate the effect of different polyether content on cured polyurethane. The components and contents used are listed in Table 5. In addition, Example 18 includes a black pigment added to the first reaction component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com