Air-discharging and air-filling device and production technology thereof for molding sulfuration molds of rubber injection hollow products

A vulcanization mold and rubber injection technology, applied in the field of rubber product technology, can solve the problems of increasing equipment cost, high energy consumption, energy waste, etc., and achieve the effect of convenient operation and guarantee of sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

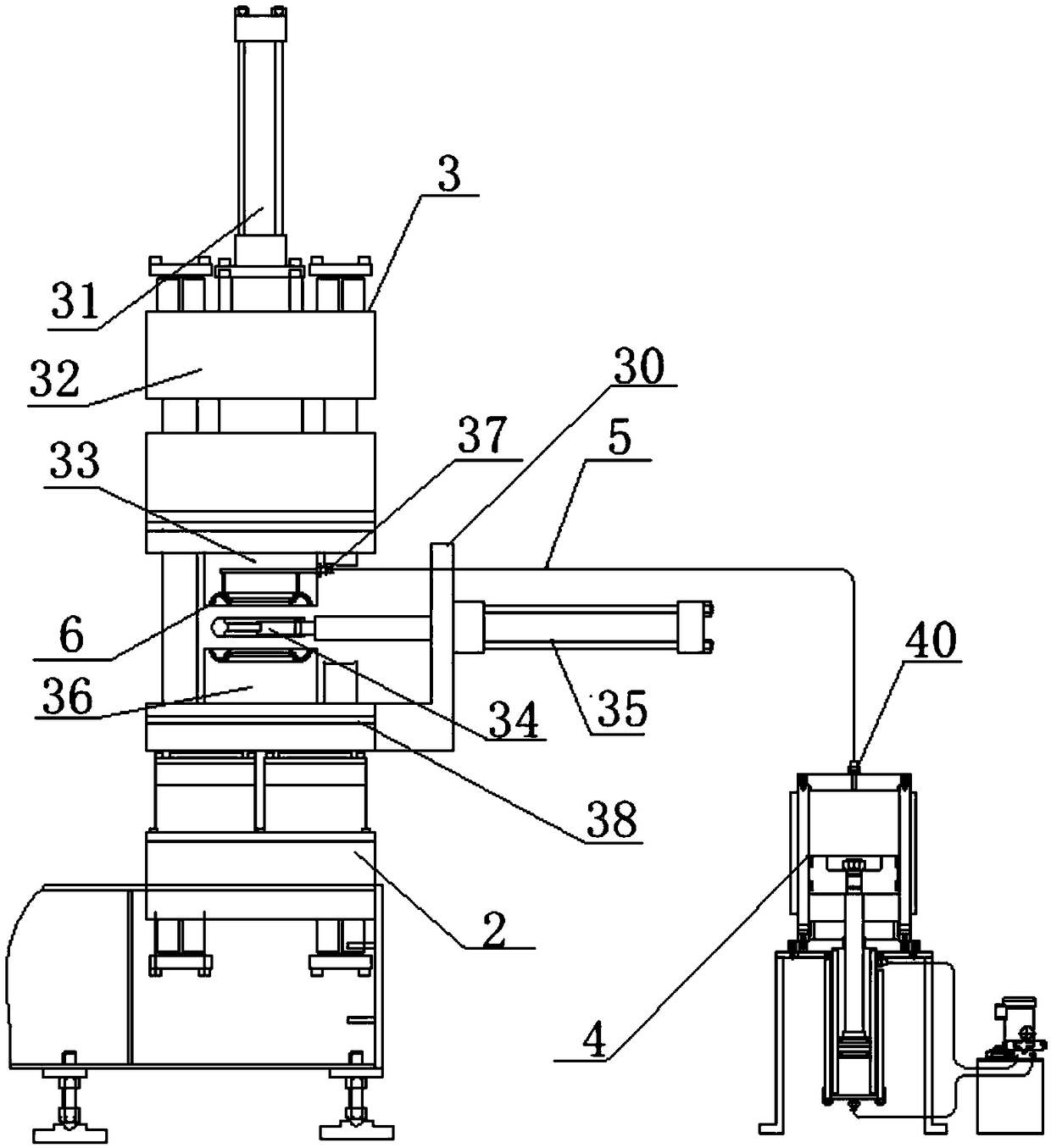

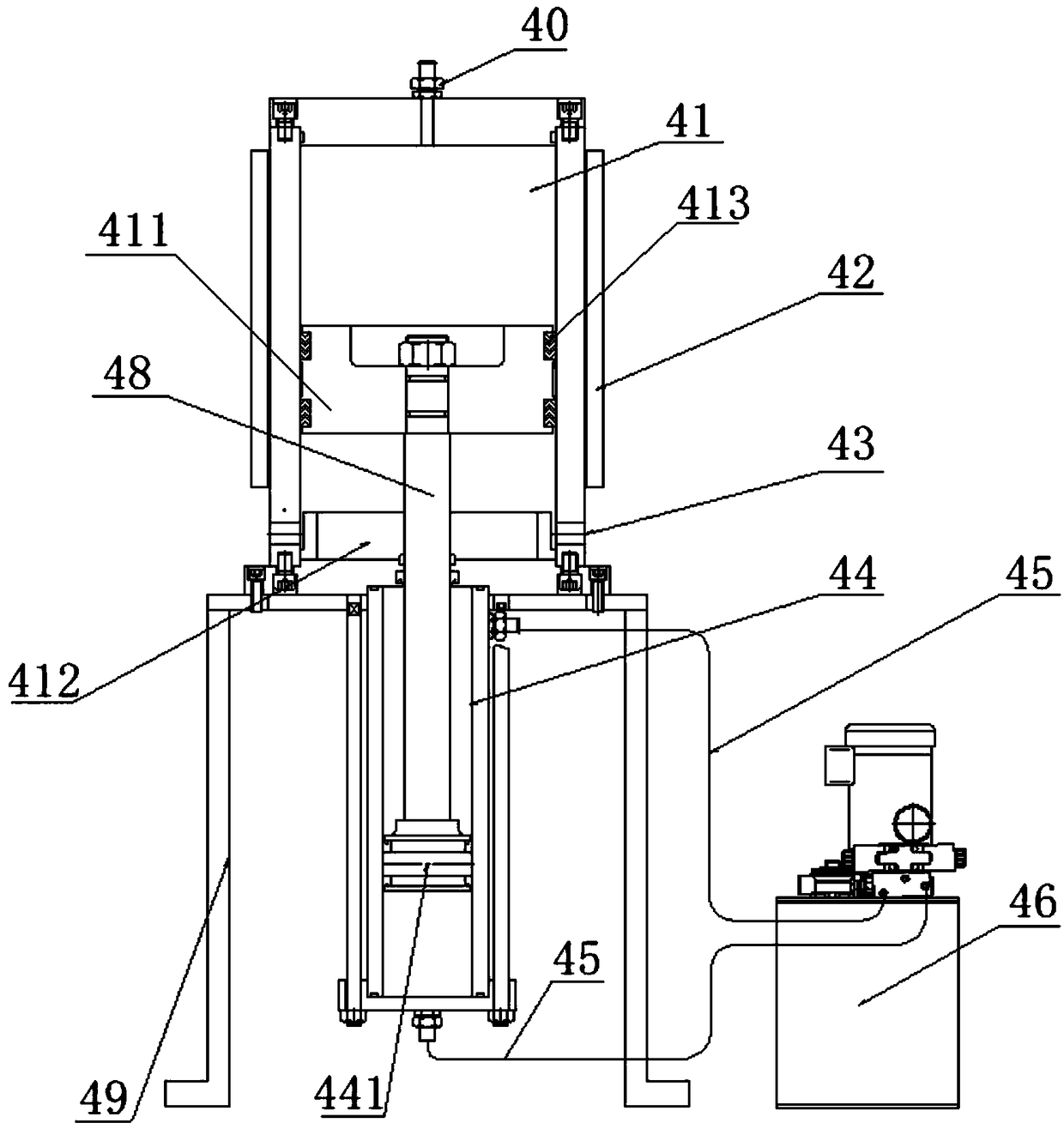

[0041] The air discharge device for the rubber injection hollow product molding vulcanization mold of the present embodiment, such as figure 1 , 2 As shown, it includes a mold vulcanization mechanism 3 and a mold exhaust and hollow inflation mechanism 4, wherein: the mold exhaust and hollow inflation mechanism 4 includes a bracket 49, a cylinder 41, an oil cylinder block 44 and a hydraulic station 46; the bracket 49 is the annular stand that has through hole in the middle, and described cylinder 41 is fixed on the annular table top of support 49, and described oil cylinder block 44 is fixed on the bottom of the annular table top of support 49, and described air cylinder 41 and oil cylinder block 44 are respectively Built-in cylinder piston 411 and oil cylinder piston 441 connected to the same piston rod 48, the top of the cylinder 41 communicates with the mold cavity of the die vulcanization mechanism 3 through the air pipe 5; the cylinder body 44 is divided into an upper cavi...

Embodiment 2

[0044] The basic structure of the exhaust and inflation device for rubber injection hollow product molding vulcanization mold of this embodiment is the same as that of Embodiment 1, and the improvements are as follows: figure 1 As shown, the compression mold vulcanization mechanism 3 includes a mold clamping cylinder 31, an upper half mold 33, a mold inner core 34, a mold core extraction cylinder 35 and a lower half mold 36; the upper half mold 33, the mold inner core 34 and the lower half mold 36 forms an annular cavity after closing the mold; the lower half-mold 36 is fixed on the press molding vulcanization table 2, and an upper half-mold 33 is arranged directly above the lower half-mold 36, and the upper half-mold 33 and the clamping oil cylinder 31 Removable connection; the mold clamping cylinder 31 is fixed by a fixed frame; the mold inner core 34 is detachably connected with the telescopic rod of the mold core extraction cylinder 35, and passes the mold core between the ...

Embodiment 3

[0046] The basic structure of the inflation device for rubber injection hollow product molding vulcanization mold of this embodiment is the same as that of Embodiment 2, and the improvement is that the mold vulcanization mechanism 3 also includes a mold clamping beam 32, and the hydraulic rod of the mold clamping cylinder 31 After passing through the guide hole of the mold clamping beam 32, it is fixedly connected with the upper half mold 33; the mold clamping beam 32 is fixed on the fixing frame of the compression molding vulcanization device 3, and the mold clamping beam plays a role in positioning, guiding and stabilizing the opening and closing of the mold The triple action effect, and thus ensure the stability of sealing and vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com