Piston engine

A piston-type, mechanical technology, applied in the direction of pistons, reciprocating piston engines, mechanical equipment, etc., can solve the problems of inability to prevent wear and reduce inertial force, and achieve the effects of wear and efficiency improvement, large inertial force and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

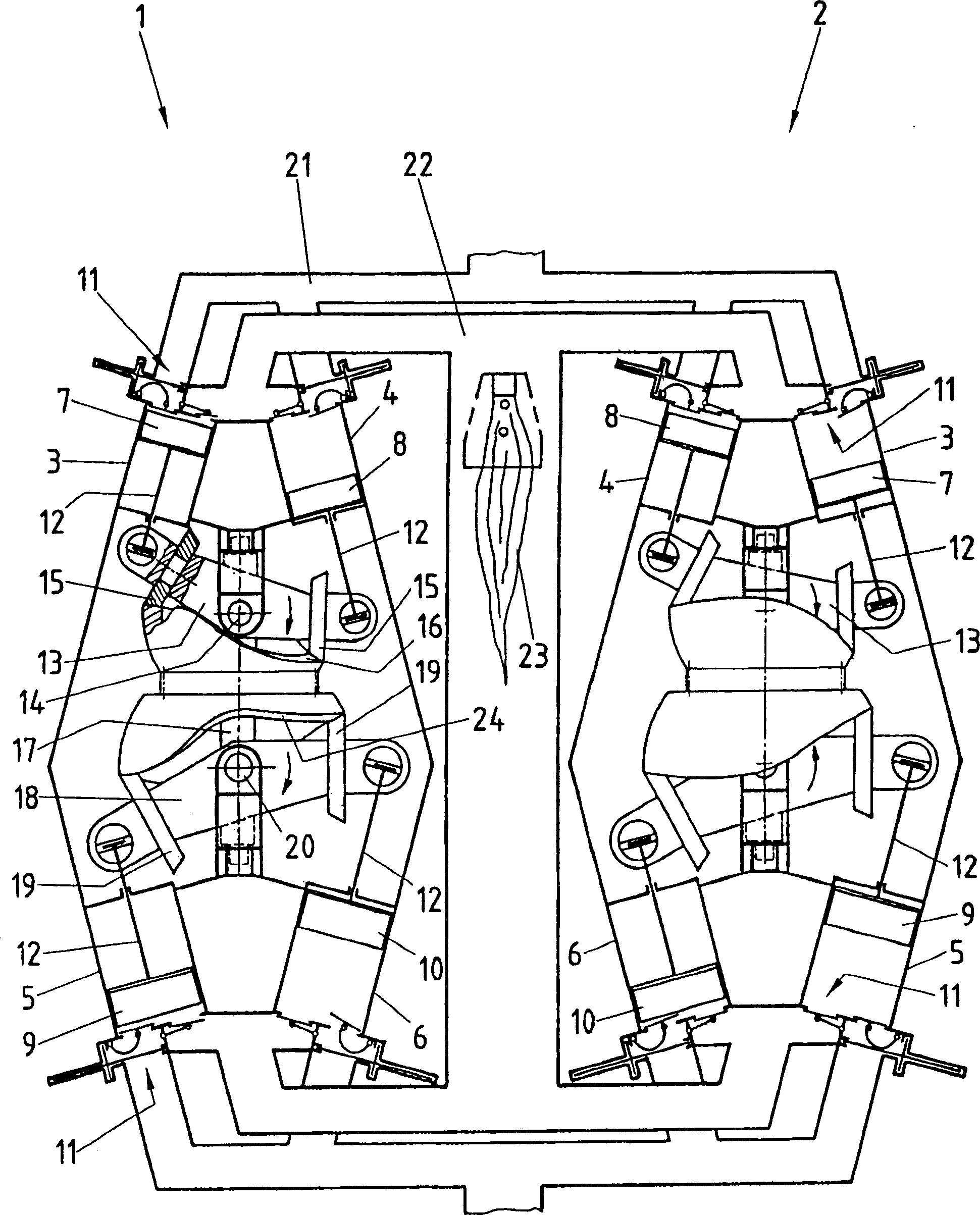

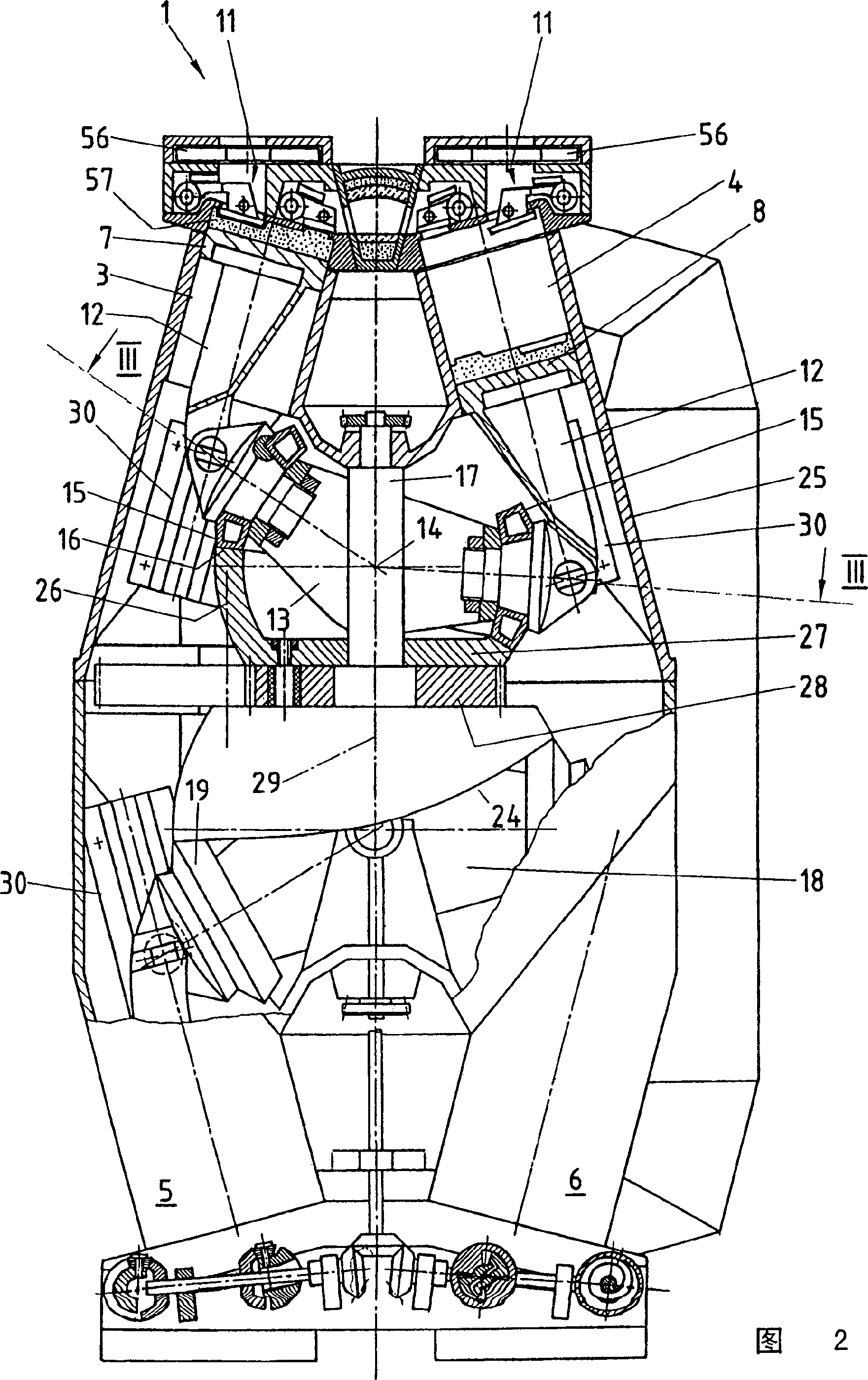

[0031] Such as figure 1 As shown, the piston machine designed as a heat engine comprises two banks 1 and 2 with four cylinders 3, 4, 5 and 6 each. Arranged in each cylinder 3, 4, 5 and 6 is a piston 7, 8, 9 or 10, which can move linearly. Each cylinder 3 to 6 is provided with a valve device 11, with this device just can open and close the air inlet or exhaust hole of each gas 3 to 6, and these valve devices 11 also hereinafter described in detail.

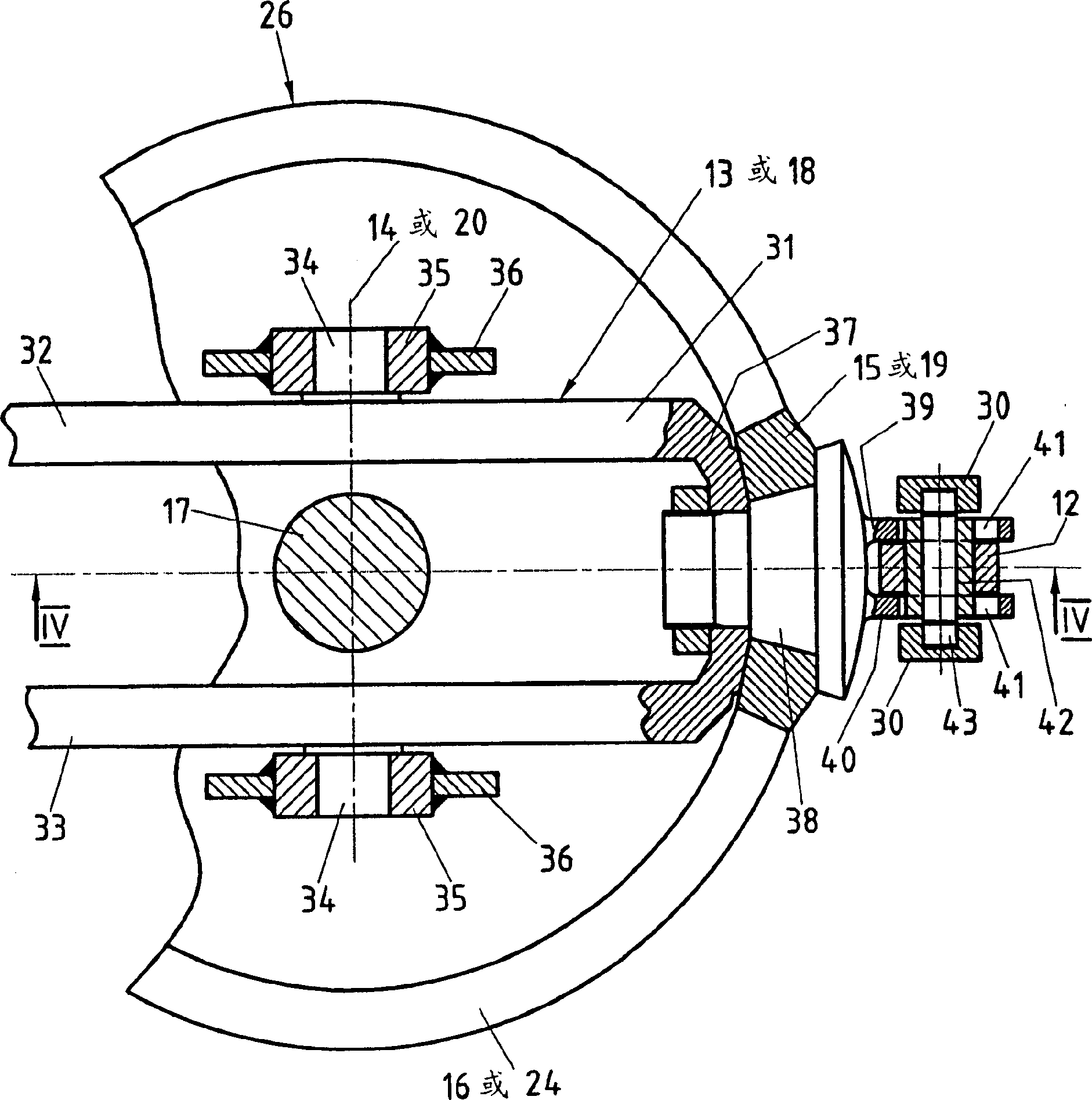

[0032] A connecting rod 12 is fixedly connected to each of the pistons 7, 8, 9 and 10. The connecting rod 12 connected with the piston 7 moving in the cylinder 3 is hinged on one end of the rocker 13 . The connecting rod 12 of the movable piston 8 in the cylinder 4 is articulated on the other end of the rocker 13 . The rocker 13 can pivot centrally around a pivot axis 14 which is fixed on the housing of the piston mechanism, as will be described in more detail below.

[0033] Similarly, a roller 15 is respectively arranged at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com