Electric dust collector

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction filters, cleaning filter devices, etc., can solve the problem of long distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

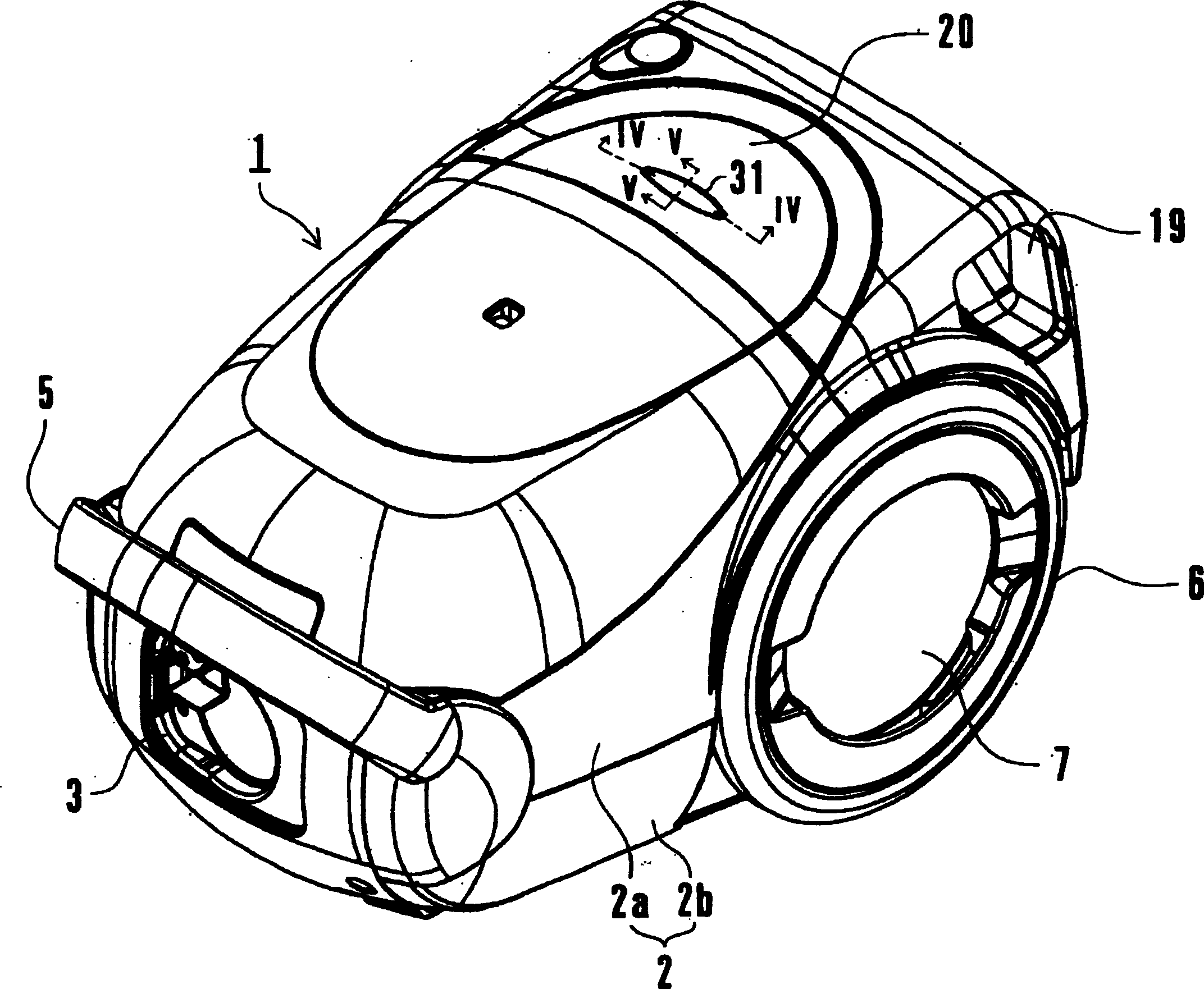

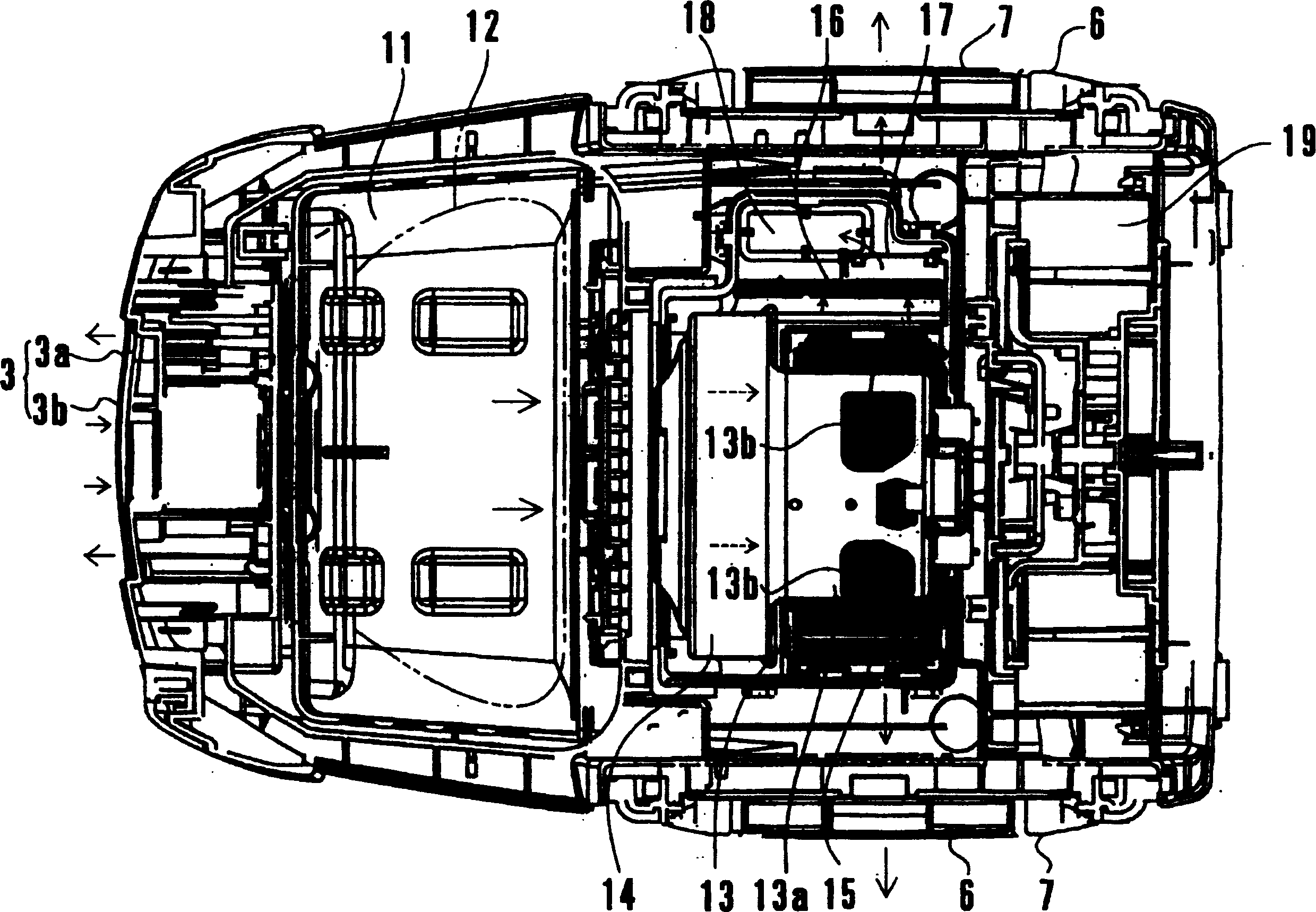

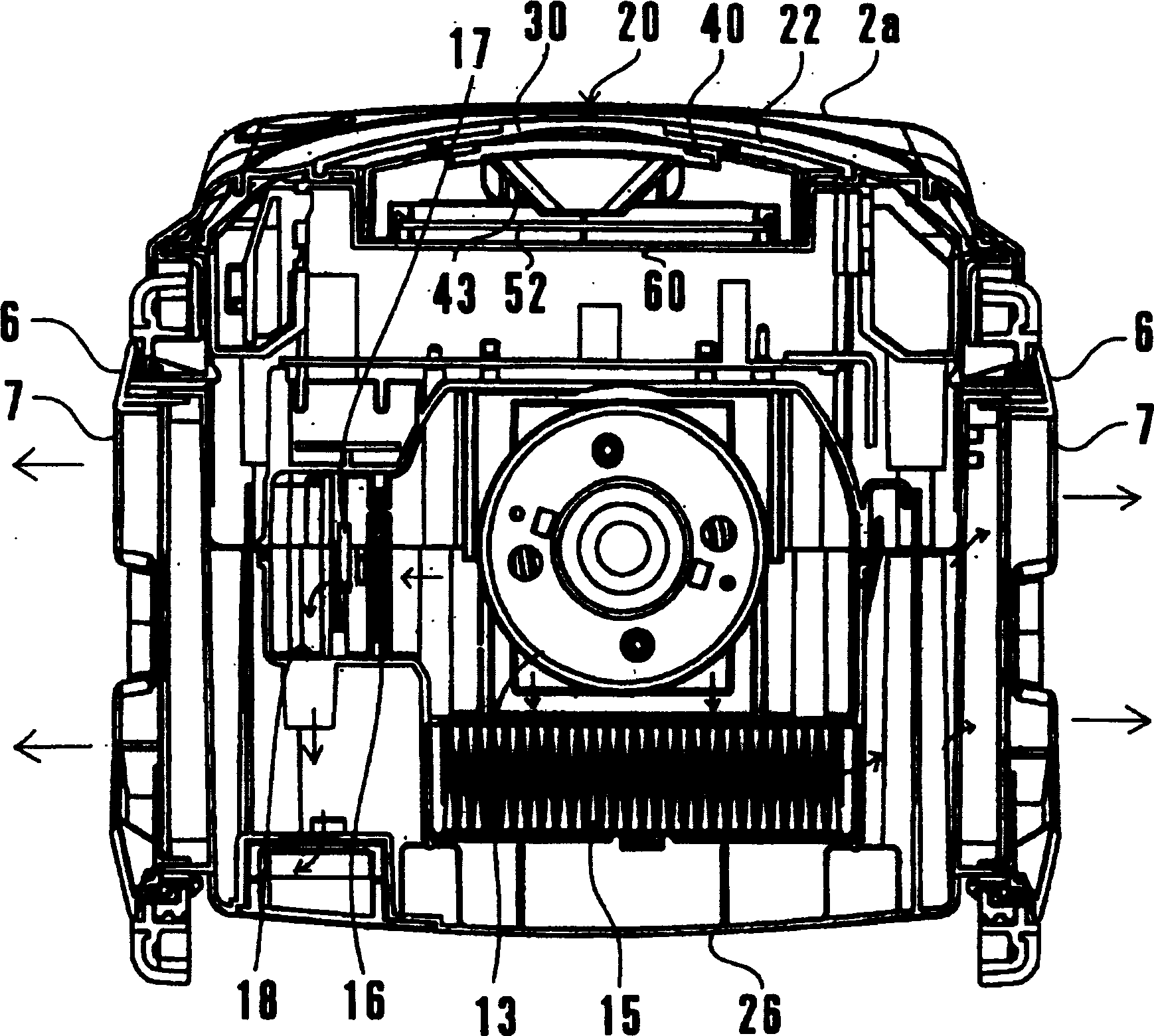

[0022] Below, according to Figure 1 to Figure 6 Examples of the present invention will be described. figure 1 It is an external perspective view of the vacuum cleaner body of the electric vacuum cleaner according to the embodiment of the present invention. figure 2 It is a top view of the state where the upper case of the vacuum cleaner main body was removed. image 3 It is a front sectional view of the vacuum cleaner body. Figure 4 yes figure 1 Sectional view of line IV-IV in the middle. Figure 5 In the state where no external force acts on the display lens, figure 1 The cross-sectional view of the V-V line in the middle. Figure 6 In a state where an external force acts on the display lens, figure 1 The cross-sectional view of the V-V line in the middle. and, figure 2 and image 3 In , solid or dashed arrows indicate the air flow direction.

[0023] The electric vacuum cleaner of embodiment, in figure 1 The hose connection port 3 of the shown vacuum cleaner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com