Comprehensive intelligent temperature control method for smelting furnace of glass kiln

A temperature control method and glass furnace technology, applied in glass furnace equipment, glass manufacturing equipment, program control and other directions, can solve the problems of temperature stability, lack of energy saving, effective control, etc., to achieve timely adjustment, ensure effective control, combustion stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

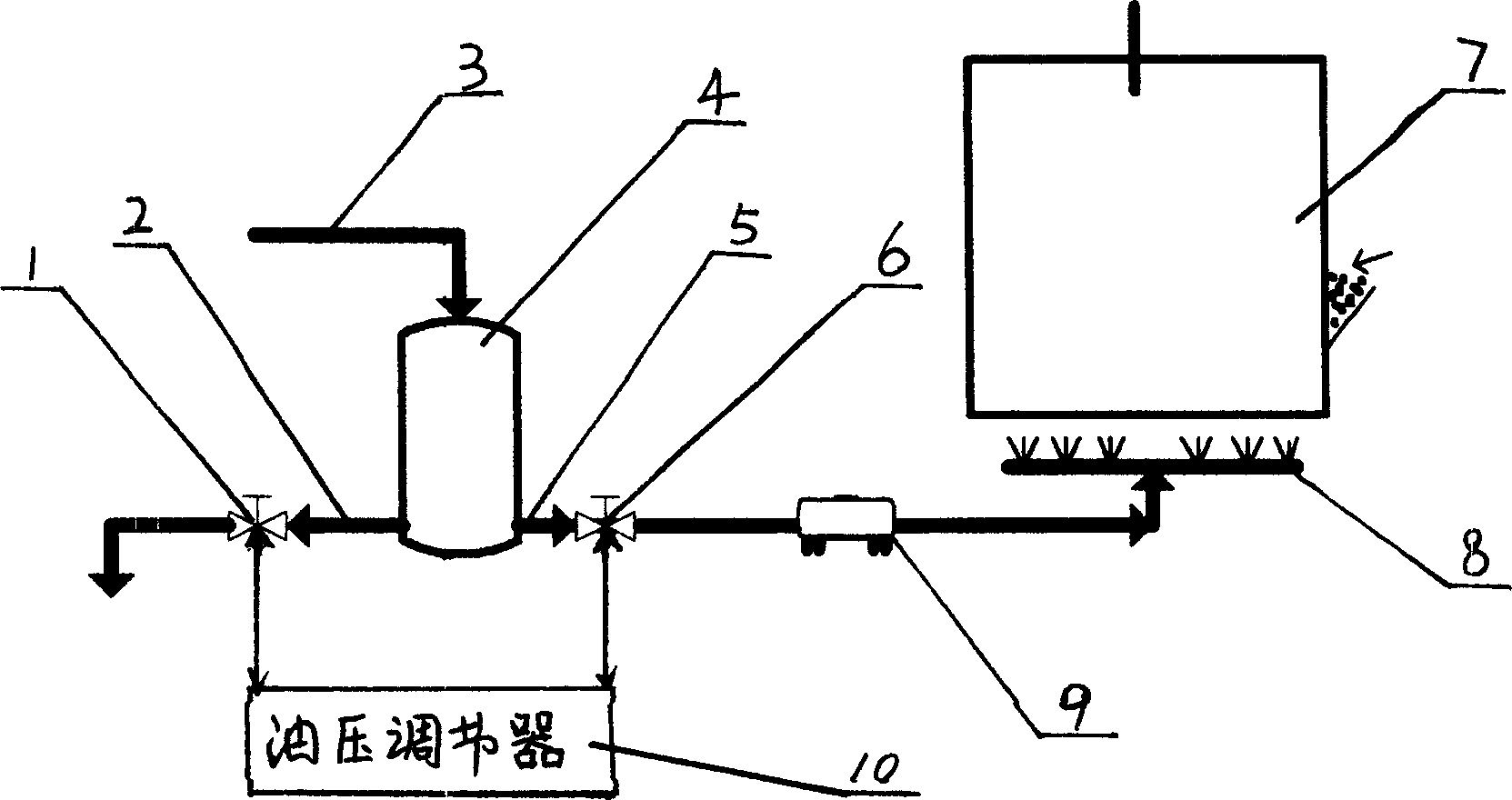

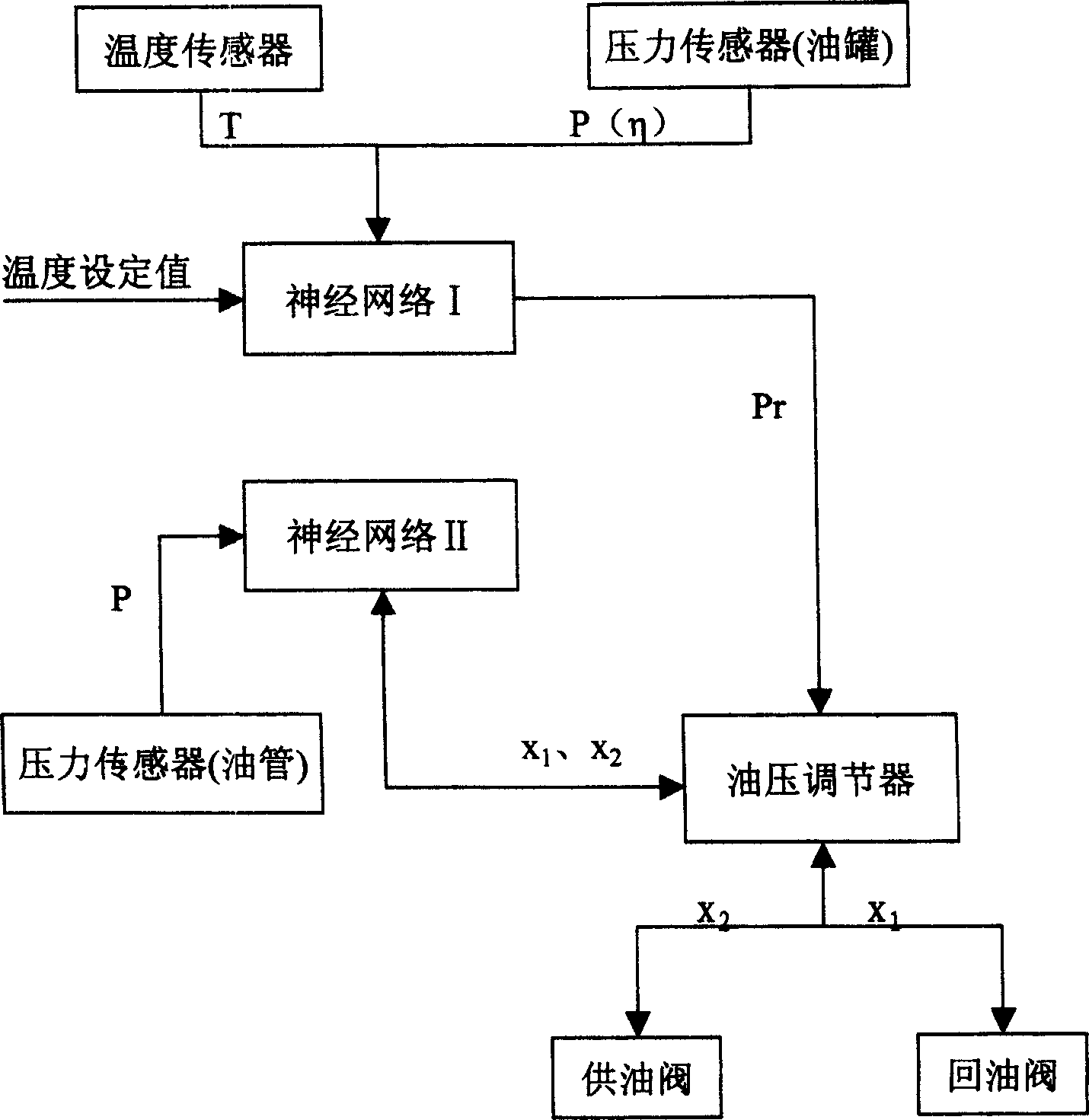

[0015] The comprehensive intelligent melting furnace temperature control method for glass furnaces of the present invention is used for glass melting furnaces that use heavy oil as fuel. The schematic diagram of the equipment structure is as follows figure 1 As shown, its equipment includes an oil tank 4, an oil pressure regulator 10, an oil supply valve 6, and an oil return valve 1. The oil inlet pipe 3 is connected to the top of the oil tank 4, and there is an oil return pipe 2 connected to the bottom of the oil tank 4. Valve 1, the oil supply pipe 5 connected to the bottom of the oil tank 4 has an oil supply valve 6, the oil supply pipe 5 is connected to the spray gun 8 through the heavy oil preheating facility 9, and the heavy oil with a certain oil pressure is sprayed out through the spray gun 8 for atomization and combustion , heating the glass furnace 7 . Furnace 7 is divided into left and right parts, and corresponding spray guns 8 are also divided into left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com