Pressure swing adsorption gas separation method, using adsorbents with high intrinsic diffusivity and low pressure ratios

A pressure swing adsorption, adsorbent technology, applied in specific gas purification/separation, separation method, dispersed particle separation, etc., can solve problems such as high energy consumption and pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] Example: VPSA performance comparison---oxygen production

[0078]A series of pilot plant tests were carried out with adsorbents Z-0 and Z-2 (as described in Table 1 above) to verify the benefits of the present invention for VPSA air separation. In all the tests, the adsorption pressure was maintained at about 1.5 bar, while the desorption pressure was changed so that the pressure ratio reached the requirements of 5.1, 3.3, and 2.6. Note that the term "pressure ratio" is defined as the pressure ratio of the adsorption to desorption process, and the measurement is carried out at the end of adsorption and desorption respectively.

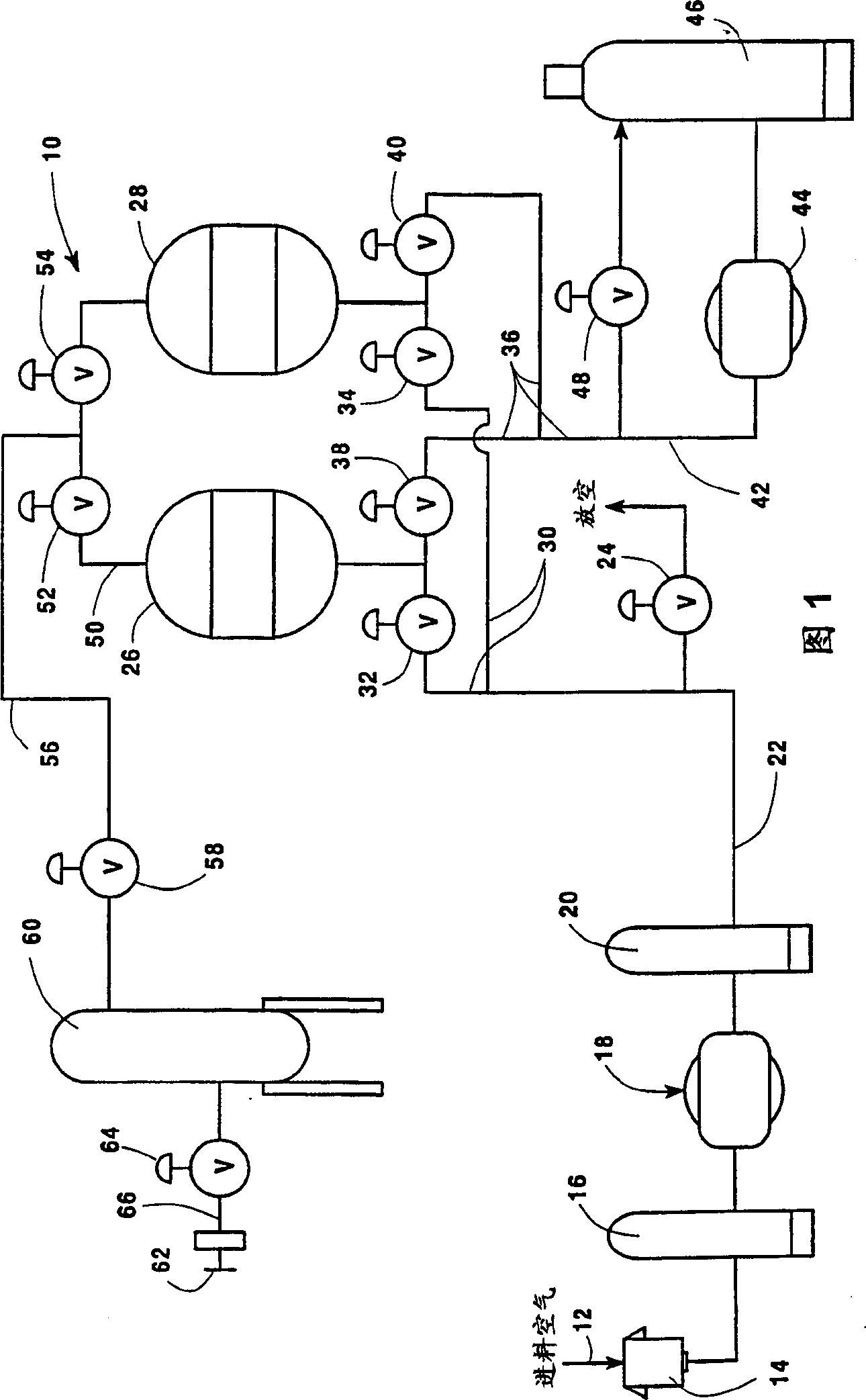

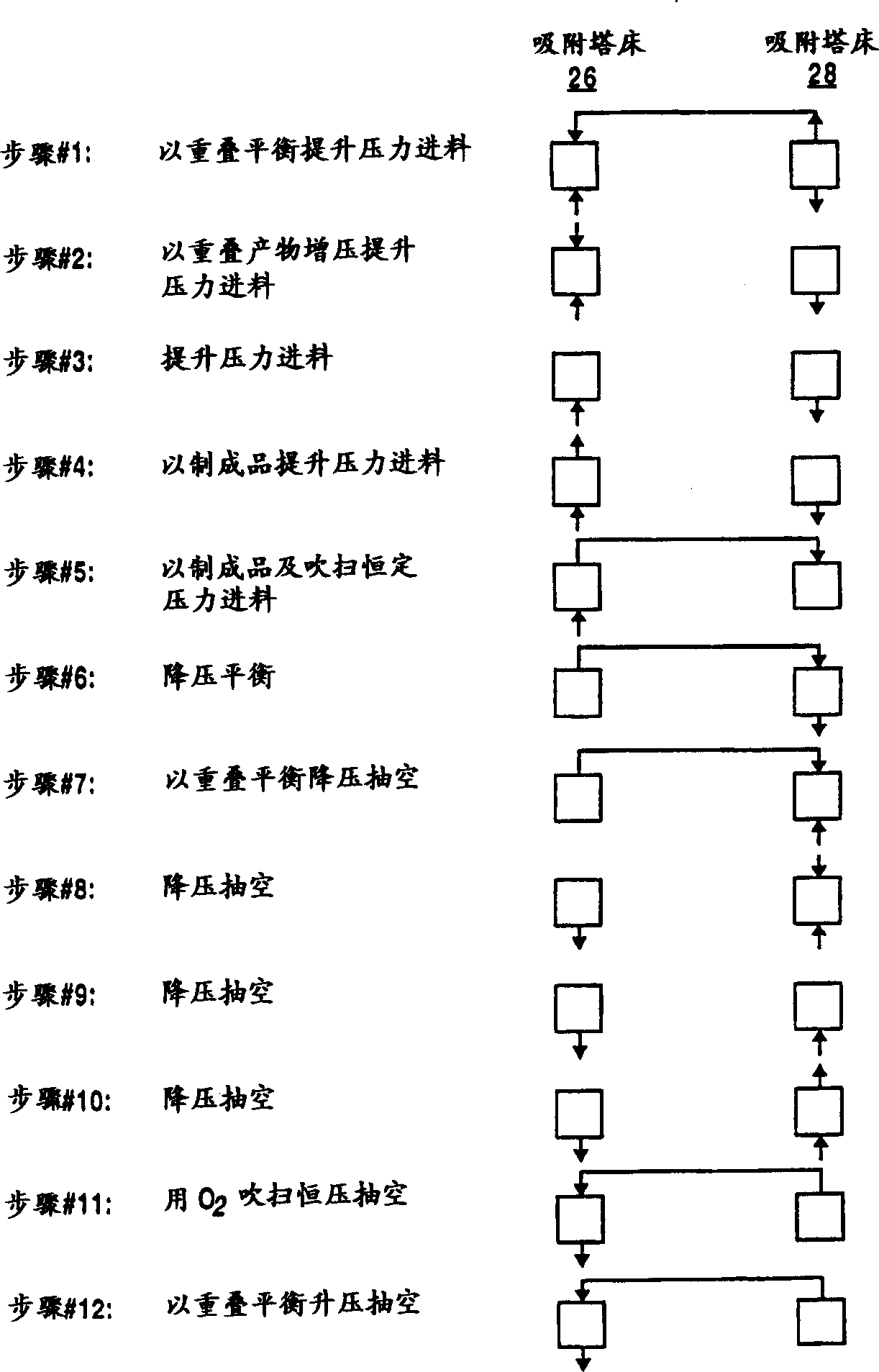

[0079] The intermediate plant is composed of two beds, the operation of which is out of phase, one cycle and several steps similar to those described by Bakshi et al. in US 5,518,526. The details are as follows. The performance results for producing 90% purity oxygen are summarized in Table 2 below.

[0080] Table 2

[0081] The performance improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com