Method for preparing low cis-polybutadiene by stepwise excitation

A butadiene and low-cis technology, applied in 1 field, can solve problems such as difficult control, complicated polymerization operation, difficult reaction control, etc., to reduce the amount of initiator and coupling agent, increase molecular weight distribution, and improve gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

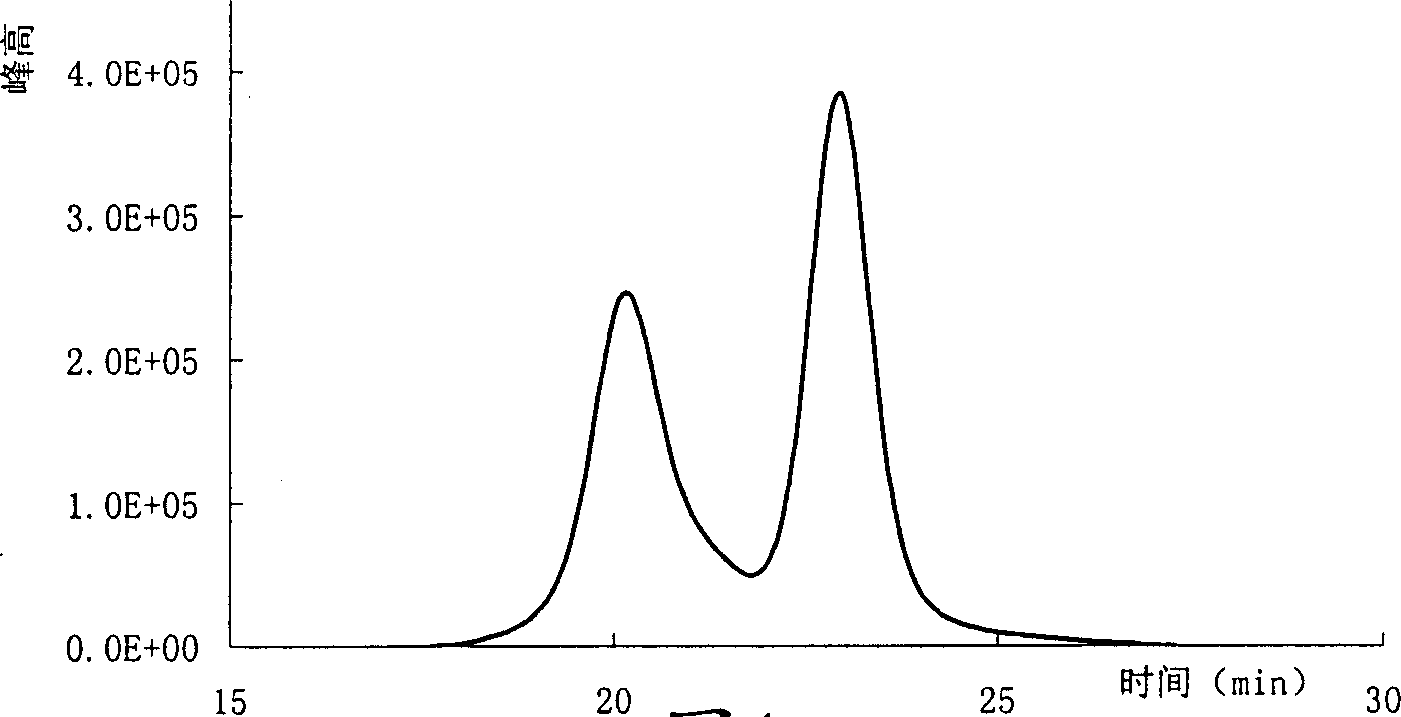

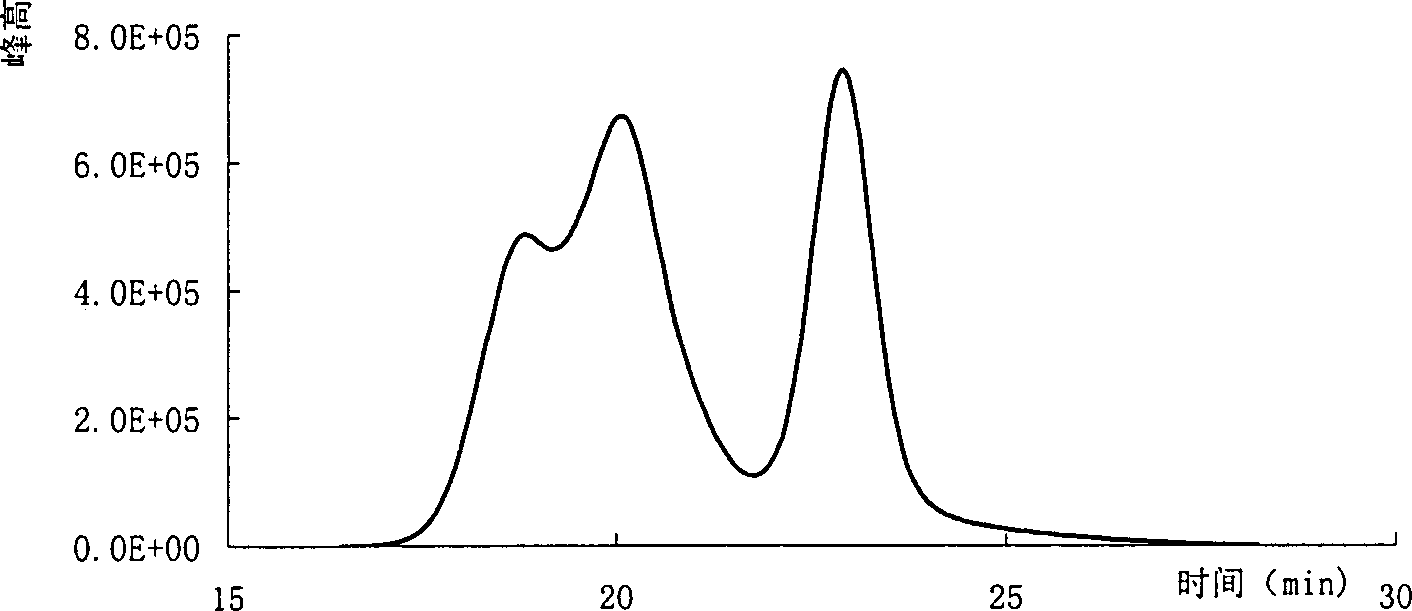

Image

Examples

Embodiment 1A

[0040] The raffinated oil is soaked with activated molecular sieves before use, so that the water content in the solvent is lower than 5ppm, deoxidized with high-purity nitrogen, and left standing for later use.

[0041] Before n-butyllithium is used, it is titrated by a double titration method, and the concentration is calibrated, and the impurity content is controlled below 5%.

[0042] Tetrahydrofuran is soaked with previously activated molecular sieves, diluted with a polymerization solvent, and deoxidized with high-purity nitrogen.

[0043] Batch polymerization was carried out in a 10-liter polymerization tank. Firstly, 4200 g of refined raffinate, 572 g of butadiene monomer and 2.36 mmol of tetrahydrofuran were sequentially added into the tank with high-purity nitrogen. When preheating to 50°C, the number average molecular weight is 660,000 for the first initiation at 0.1 MPa, and 0.87 mmol of n-butyllithium is added to initiate polymerization. When the conversion rate r...

Embodiment 1B

[0045] Cyclohexane was used as the solvent, dioxane was used as the polar regulator, and it was added according to DOX / RuLi=1.5:1; the number average molecular weight was designed to be 660,000 for the first initiation, and 0.87 mmoles of n-butyllithium was added to initiate polymerization, and the conversion rate reached 23 % by adding the secondary initiator in a mol ratio of 4: 1 with the initial initiation amount, other conditions and operations are the same as in Example 1A, and the analysis results are as shown in Table 1.

Embodiment 1C

[0047] The solvent is hexane, the polarity regulator is trichlorobenzenebicyclo[2,2,2]octane, added according to DSBCO / RuLi=0.3:1, the number average molecular weight of the first initiation design is 570000, and 1.05 mmoles of n-butyl Lithium initiates polymerization, and when conversion ratio reaches 23%, add secondary initiator with the molar ratio of 3.3: 1 with the initial initiation amount, other conditions and operation are with embodiment 1A, and analysis result is as shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com