Apparatus for producing coiling cloth roll

A technology of equipment and cloth rolls, which is applied in the field of equipment for producing winding cloth rolls, and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

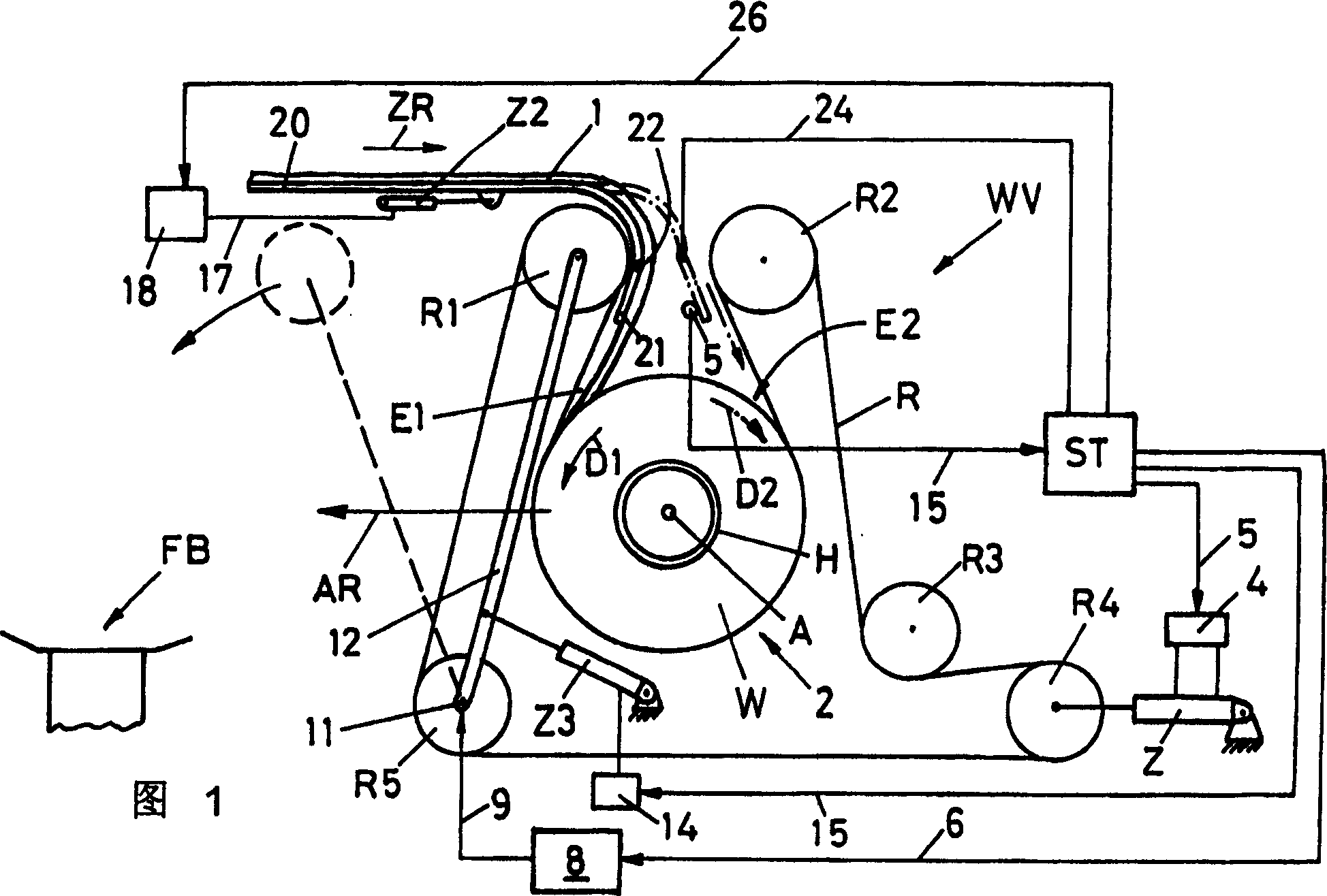

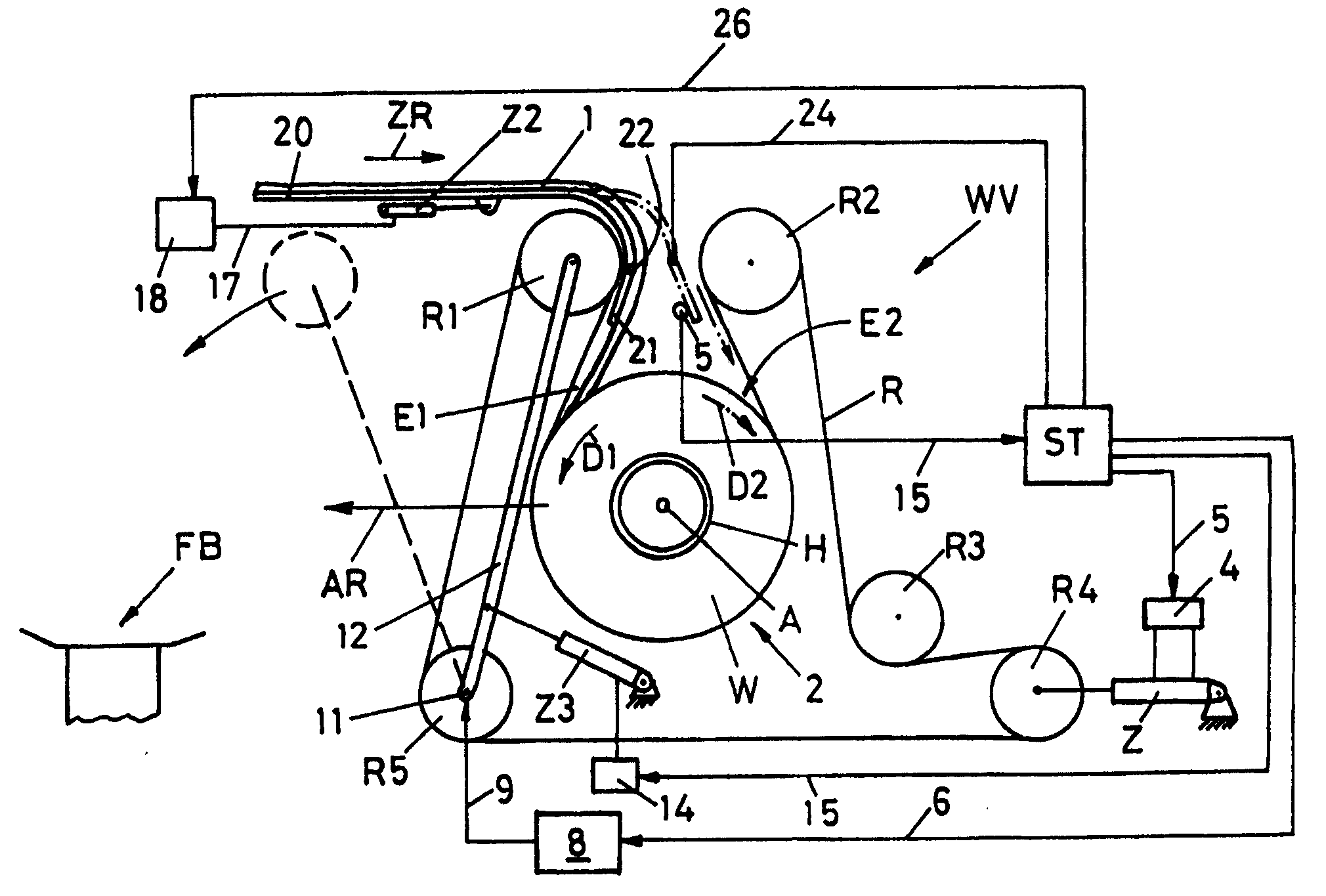

[0018] Figure 1 shows a winding device WV with a belt R guided by guide pulleys R1-R5. The belt forms a loop 2 between the guide pulleys R1, R2, in which the roll W of wound cloth is formed. The fabric 1 is guided between two guide rollers R1 and R2 and wound onto a bobbin H. As shown in FIG. The bobbin H is housed by a central disc (not shown) mounted transversely and fixedly and internally subjected to a subatmospheric pressure at least during the start of the winding process. Further details of this embodiment are described, for example, in EP-A1-799337.

[0019] As the diameter of the wound cloth roll W increases, so does the loop 2 . The belt R is under tension under the action of the rollers Z so that the wound cloth roll W is under pressure during winding by the belt R. The drum Z is controlled by a valve 4 which is controlled by means of a line 4 via a control device ST. Drive device 8 , which is activated via line 6 under the action of said control device ST, driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com