Covering material and moulded foams binded with covering material

A skin material, plastic foam technology, applied in the field of molded foam, can solve the problems of expensive, increased molded foam hardness, roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] [Formation of foam material protective layer]

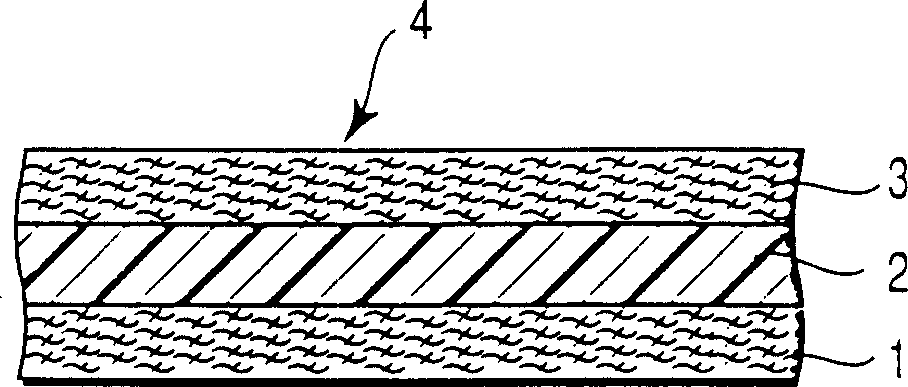

[0049] Such as figure 1 As shown, a raw material protection layer 4 comprising a first layer of nonwoven fabric 1, a plastic film 2 and a second layer of nonwoven fabric 3 is formed. Polyurethane spunbonded non-woven fabric (weight per unit area: 12g / m 2 , thickness 50 μm) was used as the above nonwoven fabrics 1 and 3. Furthermore, polyethylene film (weight per unit area: 13g / m 2 , thickness 40 μm) was used as the above plastic film 2, and the nonwoven fabrics 1 and 3 and the resin film 2 were bonded by embossing. At this time, although fine permeation was observed, the waterproof value of the obtained foam material protective layer was 130 mmaq. The peel strength between the plastic film 2 and the second layer of non-woven fabric 3 is 1.6N / 25mm.

[0050] [Formation of skin material]

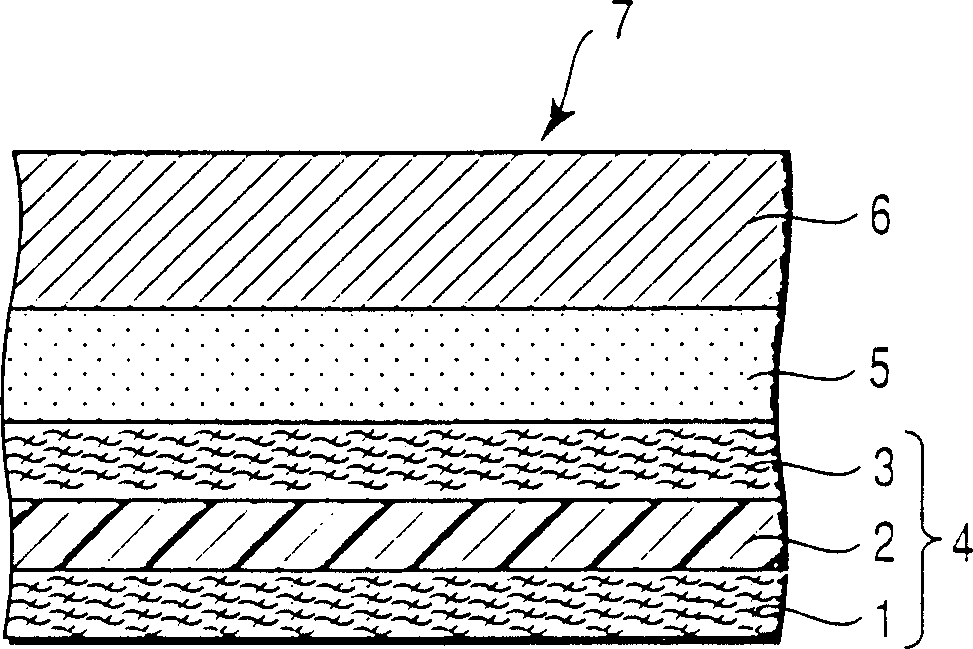

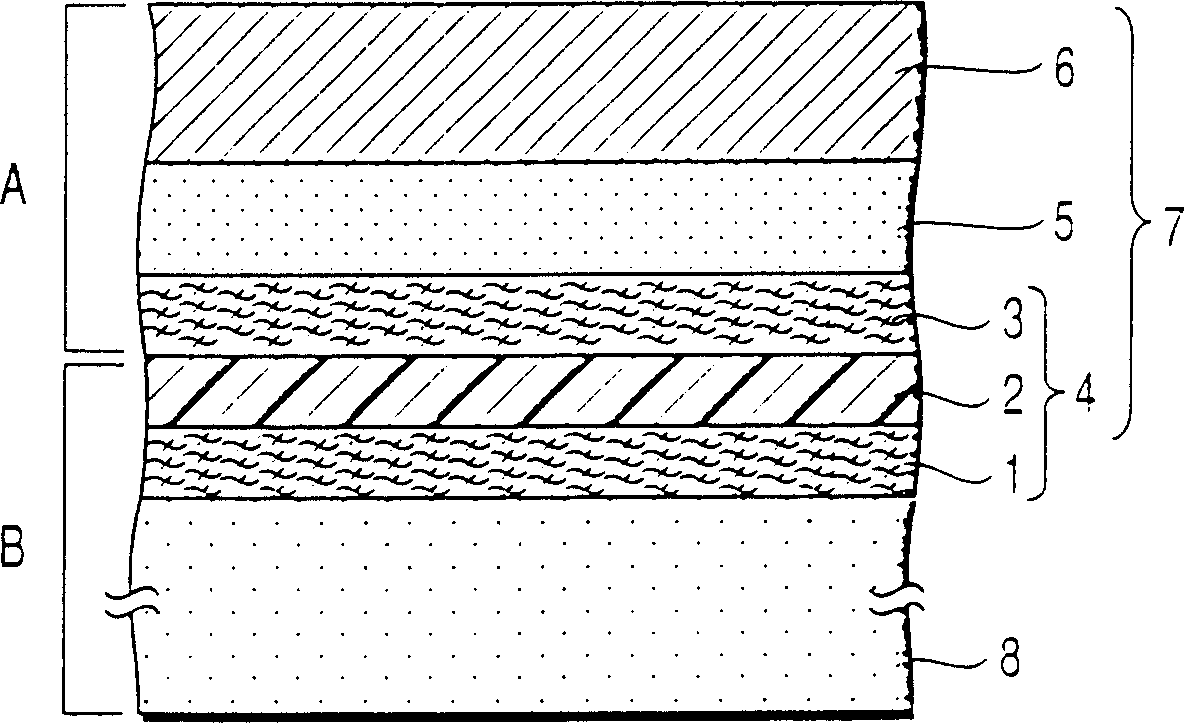

[0051] refer to figure 2 , firstly the skin (polyester jersey, product of FUKUSHURONSEN) 6 was laminated to one surface of the pla...

Embodiment 2

[0056] First, the skin material obtained in Example 1 was sewn into the target headrest form, and the skin material was arranged in a headrest mold not shown so that the skin of the skin material was in contact with the inner surface of the mold. Then, a frame is inserted, and deformable polyurethane foam raw material is injected through an inlet formed in the skin material, the foam is formed, and cured (for 30 seconds) to obtain a headrest as a molded foam bonded to the skin material.

[0057] The molded foam combined with the skin material obtained in Example 2 has the following effects:

[0058] 1) Since the plastic film 2 is sandwiched between the first non-woven fabric 1 and the second non-woven fabric 3, the molded foam combined with the skin material exhibits very little hardness. Also, since the adhesion between the second nonwoven fabric 3 and the polyurethane foam used as the pad 5 is good, there is no need to use polyethylene foam made of the same resin as the pad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com