Tyre bead with protective rib

A technology for protecting ribs and tires, applied to tire parts, tire edges, wheels, etc., can solve problems such as damage to carcass reinforcement materials, dissatisfaction, and incompatibility with aesthetics, and achieve long-lasting protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

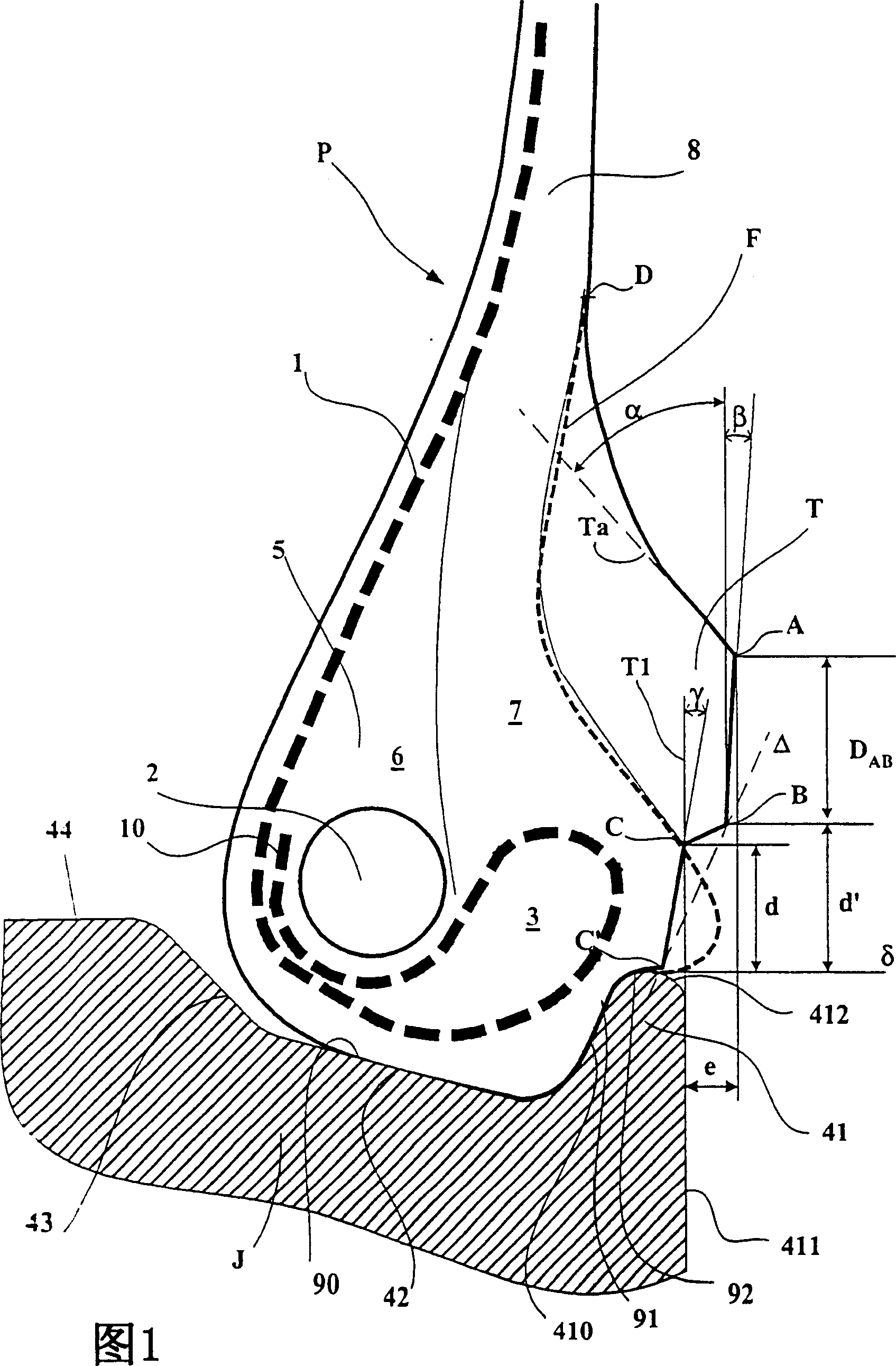

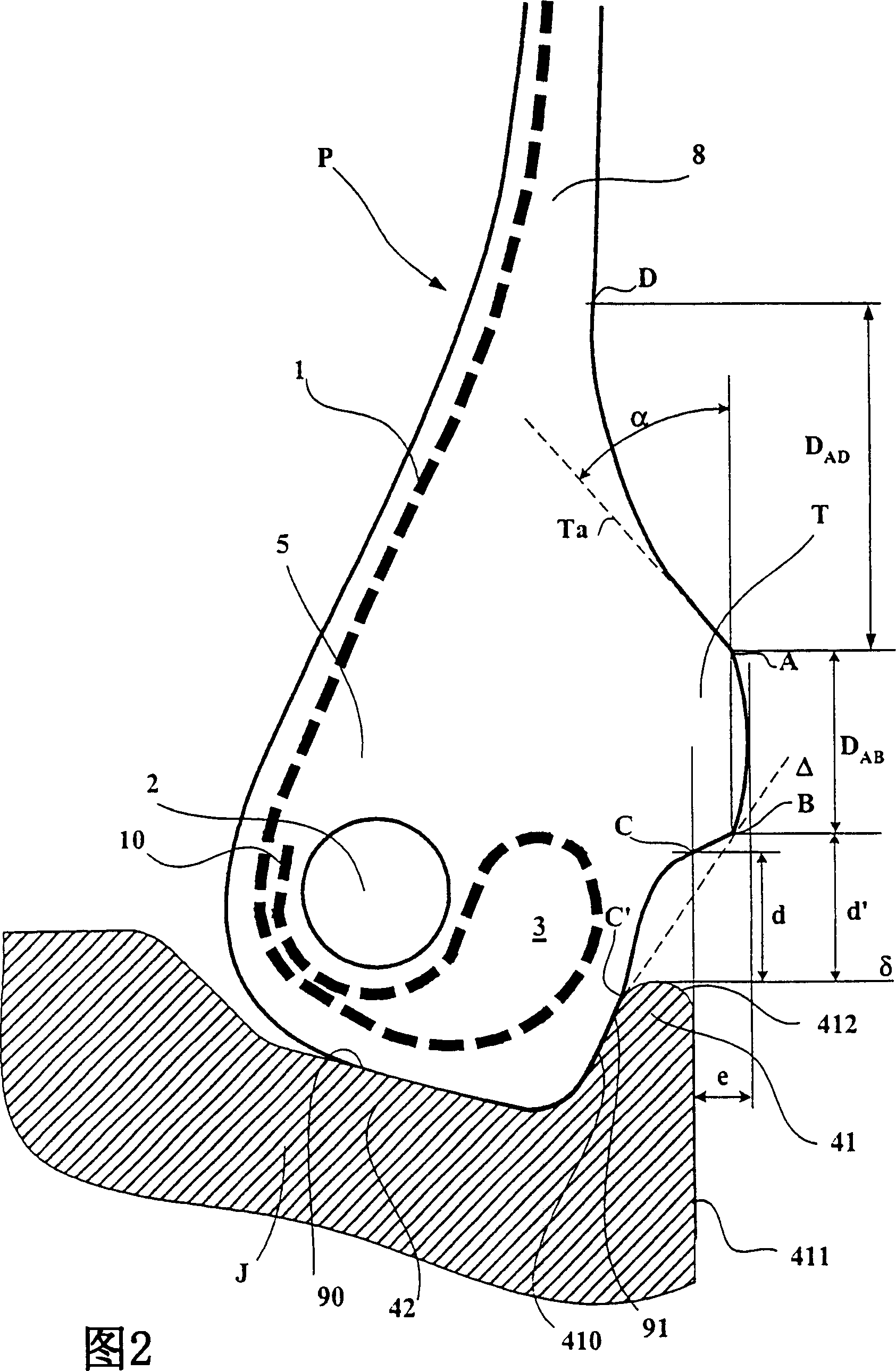

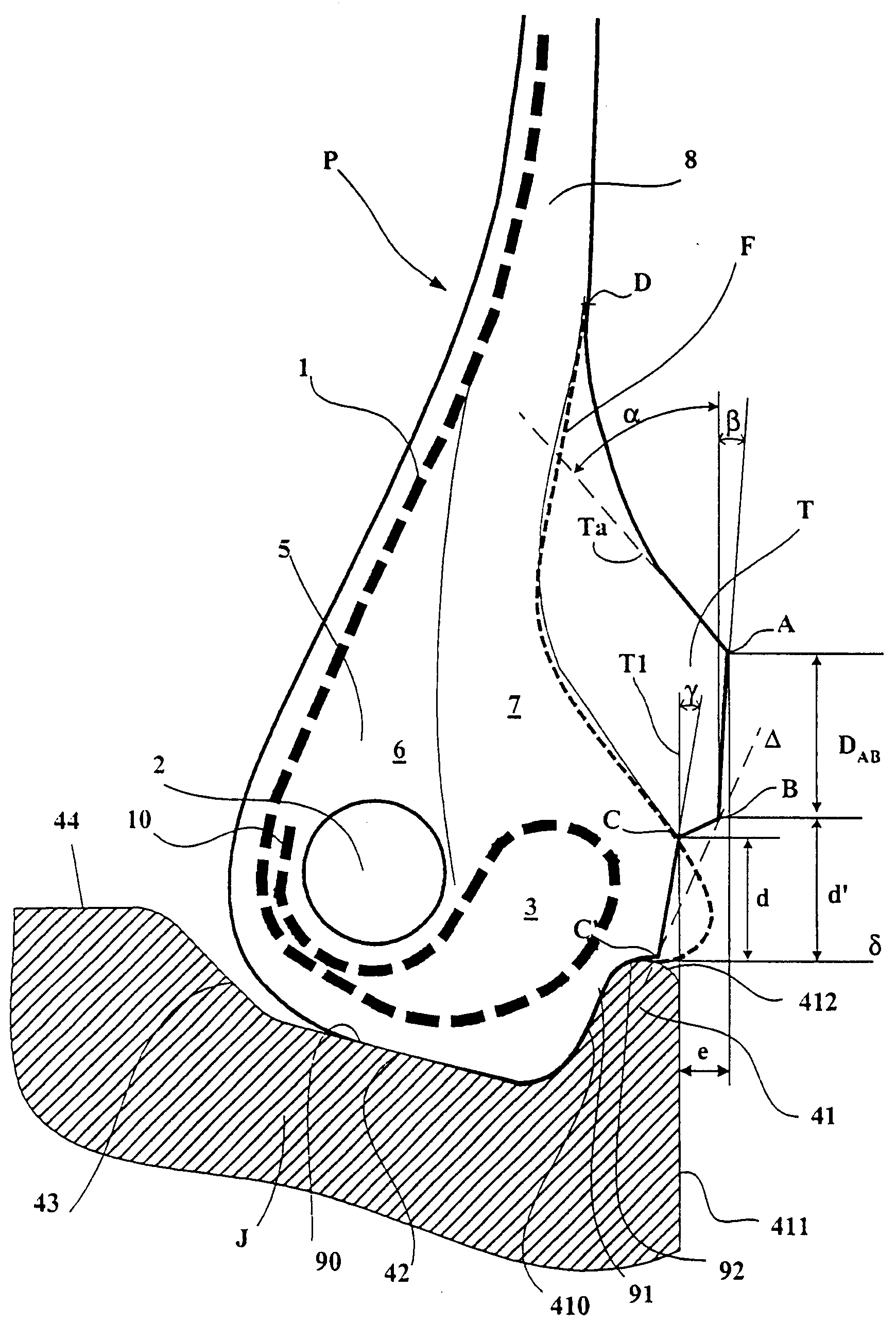

[0025] FIG. 1 shows a partial schematic meridian view of a tire P according to the invention fitted to a mounting rim J. As shown in FIG.

[0026] Figure 1 shows the sidewall 8 and bead 5 of a passenger car tire P with a specification of 205-650 R 440 A, including carcass reinforcement material 1, which passes around the bead wire 2 and extends axially from the inside of the tire. An upturned portion 10 is formed to the outside to be anchored in the bead 5 . The upturned portion 10 is arranged axially outside the bead wire 2 and completely surrounds the special-shaped unit 3 , and the bead wire 2 fixes the carcass reinforcing material 1 . Viewed from the cross section, the shape of the above-mentioned special-shaped unit 3 is roughly a triangular oblique section, and its apex is approximately below the radial direction of the bead wire 2, that is, between the rotating shaft and the bead wire, and its two sides extend from the apex. out and the third side is opposite the apex....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com