Full automatic on-line hydraulic bevel shearing machine for steel billet

A fully automatic, oblique shearing machine technology, which is applied in the direction of shearing machine equipment, shearing devices, and devices for shearing forming blanks, etc. It can solve the problems of unsuitable direct shear blades and inability to shear continuous casting billets, etc., and achieve production efficiency High, convenient billet rolling, and the effect of reducing the deformation of the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

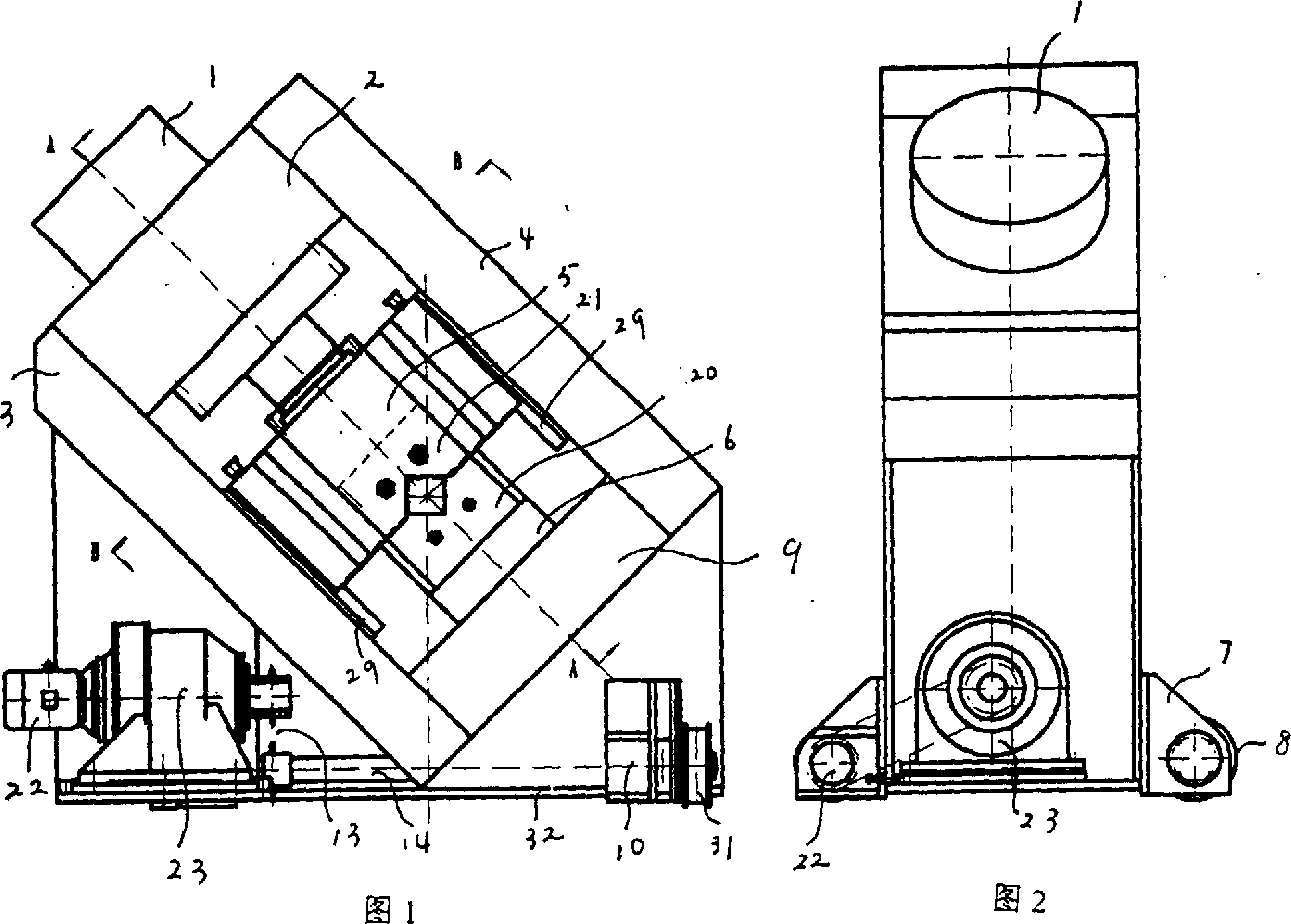

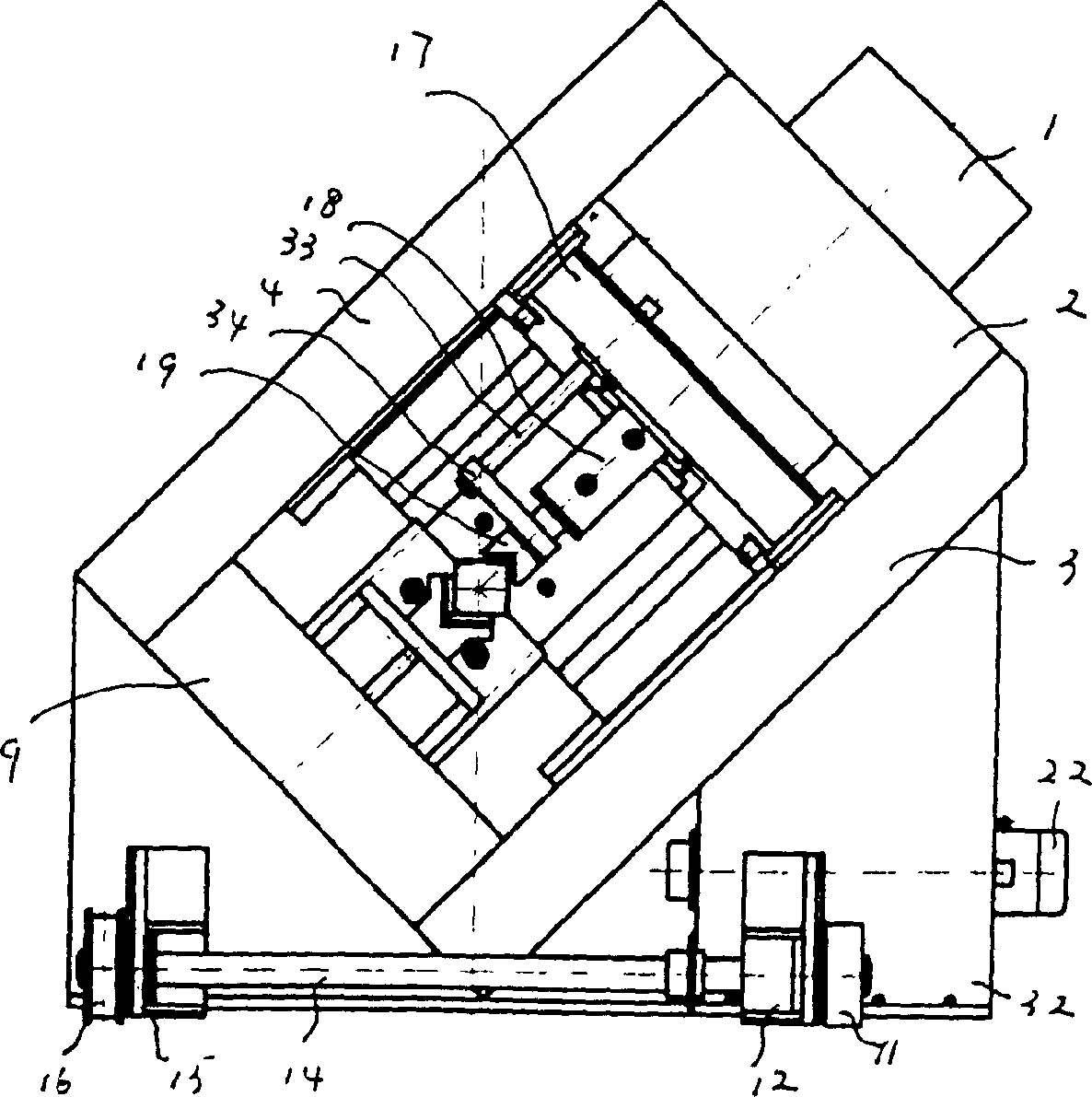

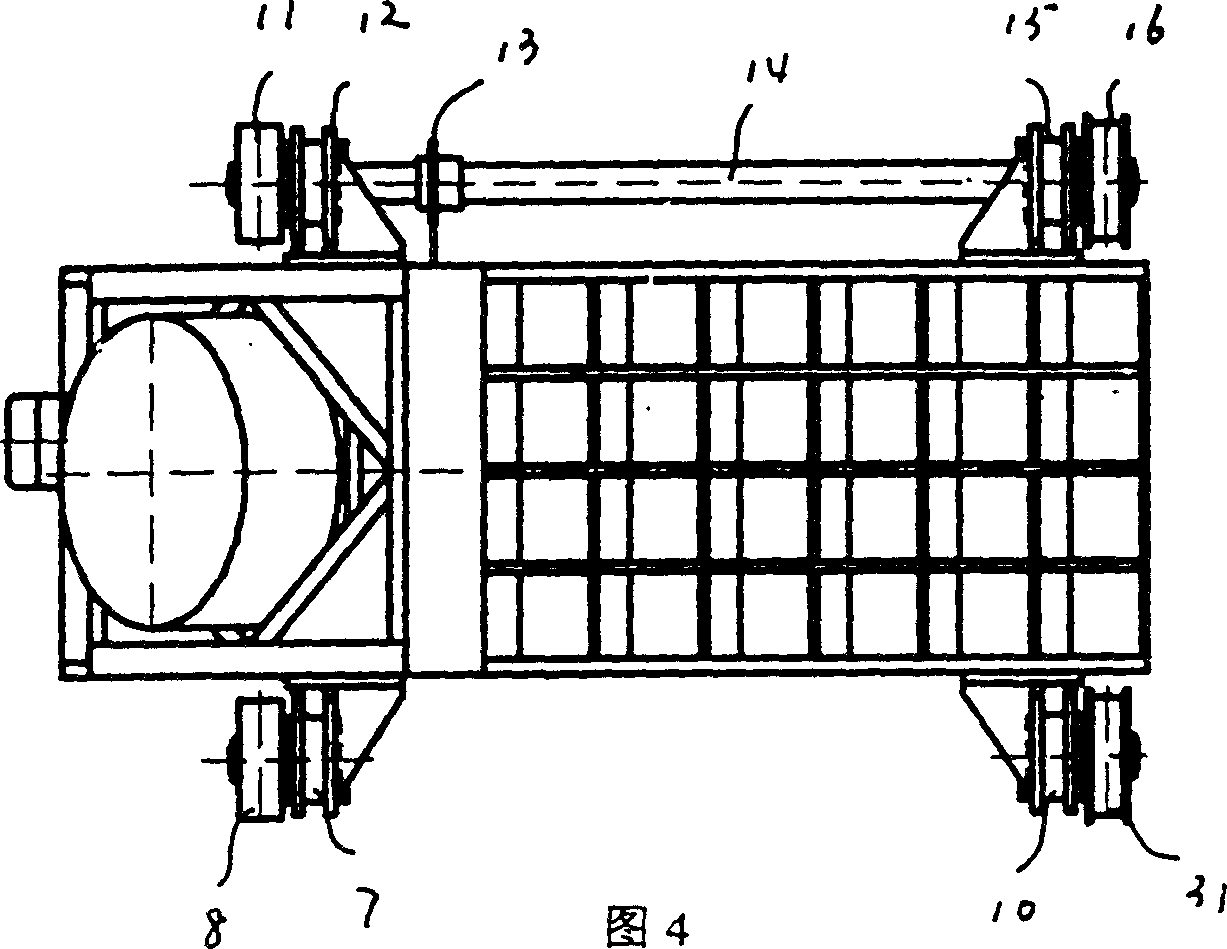

[0017] As shown in Figures 1 to 6, the present invention is a full-automatic online hydraulic billet shearing machine. It is mainly composed of base, frame, guide rail, shearing device, pressing device, traveling mechanism, hydraulic system and electrical control system.

[0018] The frame is inclined on the base 32. A square frame structure is surrounded by the left inclined side frame 3, the right inclined side frame 4, the upper inclined beam 2 and the lower inclined beam 9.

[0019] Guide rail 29 is fixed on the inner side of left inclined side frame 3 and right inclined side frame 4. A wear-resistant liner 28 is fixed on the surface of the guide rail 29 .

[0020] The shearing device is fixed by a shear cylinder 1, an upper knife seat 5, a V-shaped shear upper blade 21, a lower knife seat 6, a V-shaped shear lower blade 20, a wedge-shaped adjustment block 25, a wedge-shaped guide plate 27, and an adjustment block Screw 24, adjustment block adjustment screw 30 and guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com