Method for producing shattered preservative-free dried fruit pieces

A technology for fruit slices and fruits, which is applied in the fields of fruit and vegetable preservation, fruit/vegetable preservation by dehydration, fruit/vegetable preservation by freezing/refrigeration, etc. It can solve the problems of not being able to be used as snack food, loss of integrity, small fruit grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

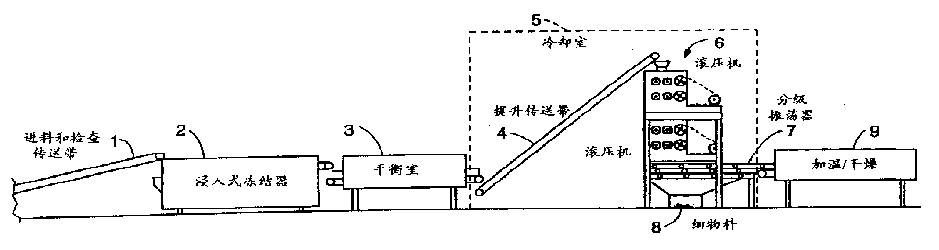

Image

Examples

Embodiment 1

[0022] Plums are harvested (typically about 80% moisture content). It is then dried in a dryer at 180°F to a moisture content of 16-17% to form low moisture, dry, whole dried plums. Since the moisture content of dried plums is usually so low that fungi and bacteria cannot grow, they can usually be stored for at least 24 months as long as they are not exposed to moisture and infection.

[0023] To pit the dried whole plums, the plums are first washed and steamed to soften them. When cooking the dried plums, the moisture content of the dried plums is increased to 28-29% to increase the efficiency of denucleation. The steamed hot plums are then pitted with an automatic plum pitter and sorted to remove any remaining pits. In all embodiments of the invention, it is necessary to remove all stones.

[0024] The pitted dried plums (28-29% moisture content) were covered with dry ice to reduce the temperature of the dried fruit to about -55 to -80°F. The frozen plums are sent to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com