Adhesive and pressure-sensitive adhesive band using the adhesive

An adhesive and adhesive tape technology, which is applied in the direction of film/sheet adhesives, adhesives, adhesive additives, etc., can solve problems such as penetration at the attachment point, and achieve effective bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

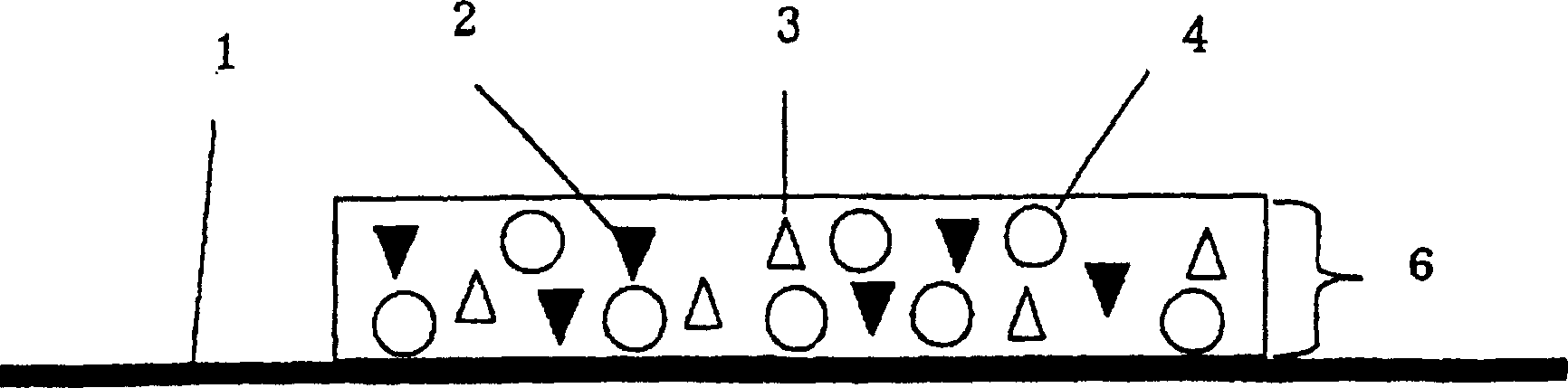

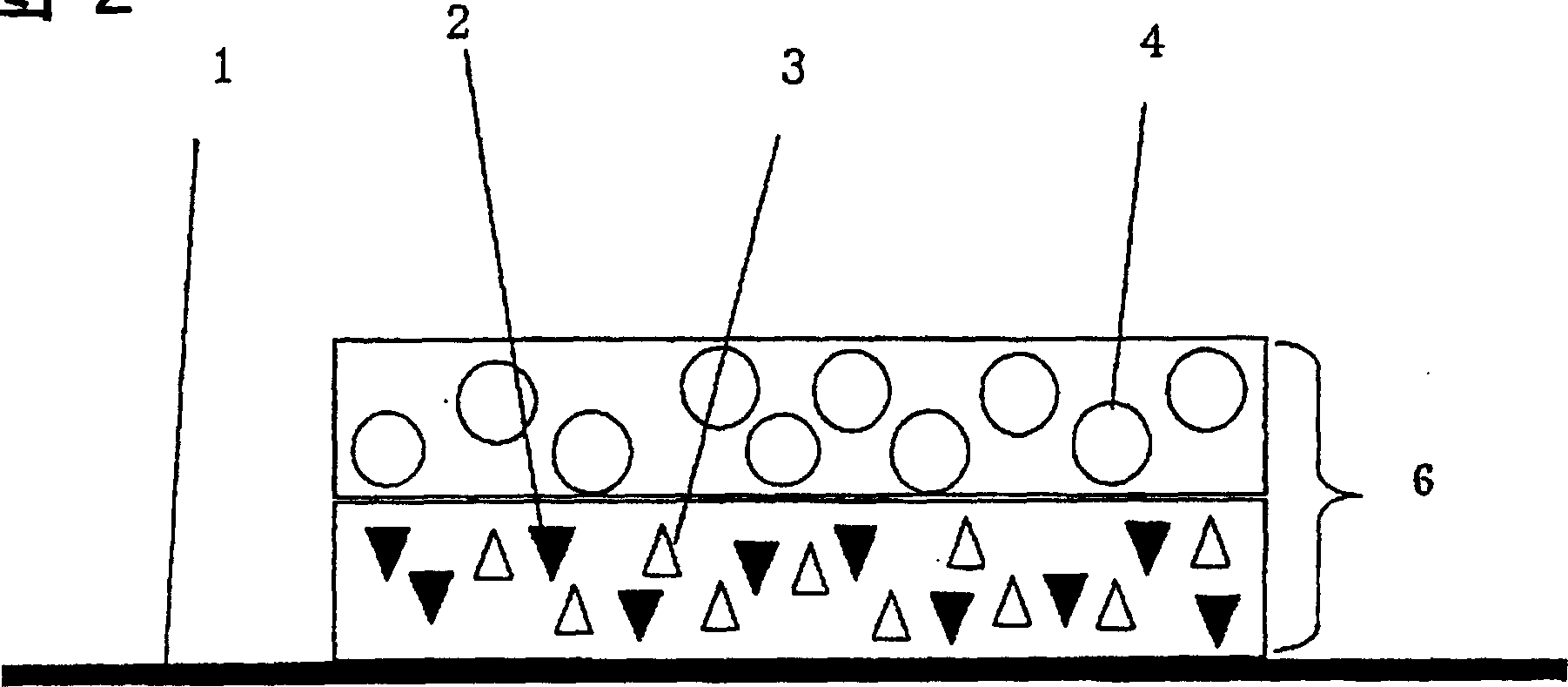

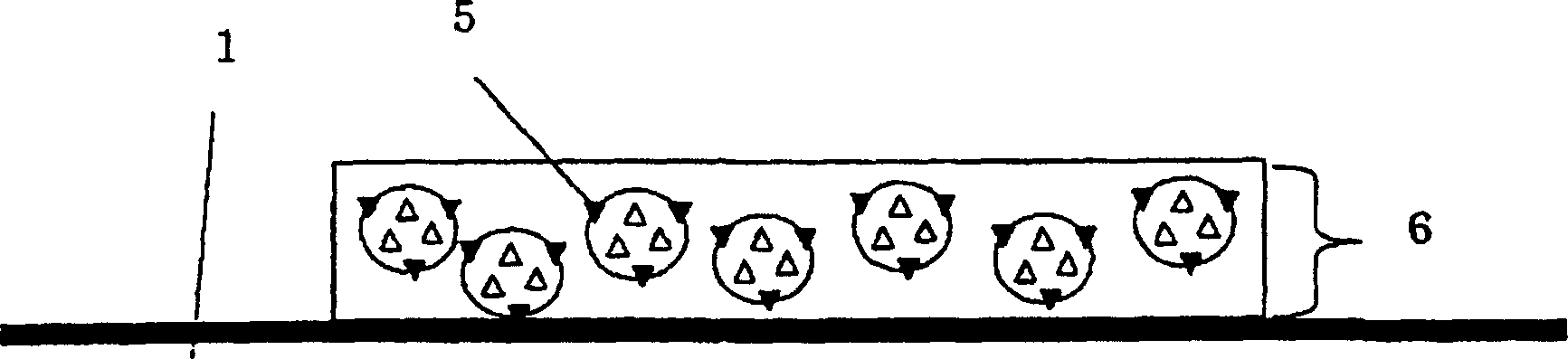

Image

Examples

Embodiment 1

[0044] By heating 10 parts by weight of crystal violet lactone (manufactured by Tokyo Chemical Industry Co., Ltd.) as a leuco dye, and 4 parts by weight of TG-SA (manufactured by Nippon Kayaku Co., Ltd.) as a developer Dissolve and stir, the color turns blue, and after cooling, it is pulverized to obtain colorant A.

[0045] Disperse the microcapsules coated with the decolorizing material dimethylaminopyridine, which can decolorize the color material A, and the isopropyl naphthalene obtained by the coacervation method, in an appropriate amount on the acrylic adhesive agent, and applied to the release-treated substrate to obtain a pressure-sensitive transfer adhesive tape.

[0046] A pressure of 1500 kPa was applied to the tape portion to transfer it to paper, and since it had a recognizable blue color at this point in time, it was possible to distinguish where it was transferred.

[0047] After one day of reposting, the blue color of the reposting position will disappear, mak...

Embodiment 2

[0049] Dissolve by heating 10 parts by weight of Blue-63 (manufactured by Yamamoto Chemical Industry Co., Ltd.) as a leuco dye, and 3.5 parts by weight of TG-SA (manufactured by Nippon Kayaku Co., Ltd.) as a color developer. After stirring, the color turns blue, and after cooling, it is pulverized to obtain colorant B.

[0050] In an acrylic-based adhesive with toluene and ethyl acetate as the main solvent, an appropriate amount of the colorant B and dimethylaminopyridine is contained, and it is coated on a substrate that has been peeled off, and the solvent is dried to obtain Blue adhesive layer X. Next, using the coacervation method, microcapsules coated with isopropylnaphthalene can be obtained, and the microcapsules can be dispersed in an appropriate amount of acrylic adhesive and stacked on the adhesive layer X to obtain pressure-sensitive Transfer adhesive tape.

[0051] A pressure of 1500 kPa was applied to the tape portion to transfer it to paper. At this point in ti...

Embodiment 3

[0054] By dissolving 10 parts by weight of crystal violet lactone (manufactured by Tokyo Chemical Industry Co., Ltd.) as a leuco dye, and 3.5 parts by weight of TG-SA (manufactured by Nippon Kayaku Co., Ltd.) as a developer Colorant liquid C was obtained in a mixed solvent of 10 parts by weight of Solmix AP-1 (manufactured by Nippon Alcohol Sales Co., Ltd.) and 15 parts by weight of toluene.

[0055] And by the interfacial polymerization method, the microcapsules coated with the decolorizing material castor oil can be obtained.

[0056] Then, 5 parts by weight of the microcapsules coated with castor oil were added to 50 parts by weight of the colorant liquid C, heated to 50° C. and stirred. After five minutes, the microcapsules are separated from the colorant solution C to obtain microcapsules whose walls are colored with the colorant composed of the leuco dye crystal violet lactone and the color developer TG-SA.

[0057] A suitable amount of colored microcapsules is disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com