Luminous reflective concrete floor tile and its producing method

A production method and concrete technology, which is applied in the field of floor tiles and its production, can solve the problems of non-reflective floor tiles, poor wear resistance and long-lasting luminous performance, and the luminescent layer of the floor tiles is easy to fall off and age, and the production method is simple. , coagulate firmly, improve the effect of lasting luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

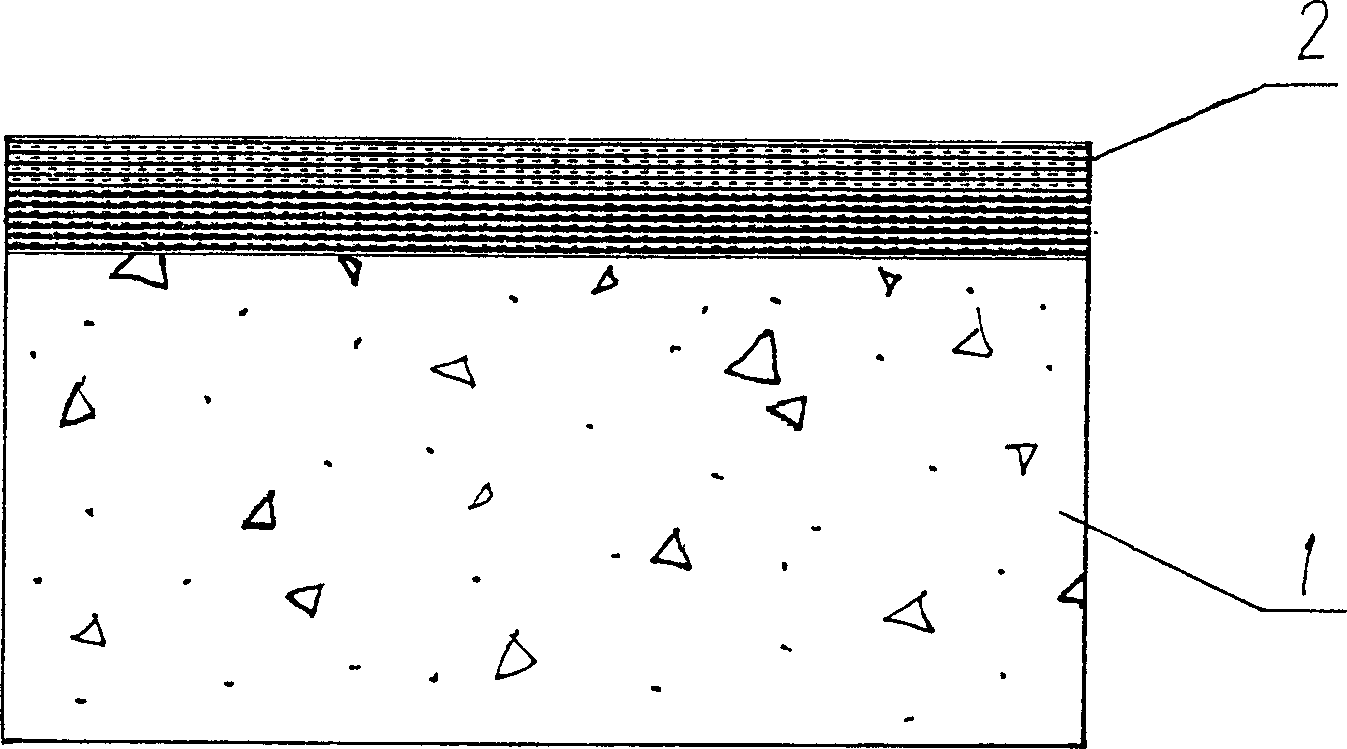

[0046] (1) Stir cement, sand, gravel, slag, toner, concrete admixture, and water according to the proportion of ordinary concrete, and pour it into the mold to vibrate and compact to form a base layer.

[0047] (2), then add 5-30% of cement, 60-85% of glass beads, 0-5% of luminous powder, 0-5% of toner, 0.1-6% of concrete admixture, reflective glass beads, and redispersible rubber powder , Add water and stir evenly, and pour it on the base layer freshly formed in the above step (1) to form a luminous reflective surface layer, and then form it through vibration compaction, so that the concrete base layer and the luminous reflective surface layer containing glass beads are coagulated as one .

[0048] (3) After demoulding, curing is carried out, and the finished product of prefabricated luminous reflective concrete floor tiles is produced in the factory.

[0049] (4) The surface of the finished product is washed, sandblasted and polished to obtain highly reflective and luminous...

Embodiment 2

[0051] (1) Stir cement, sand, gravel, slag, toner, concrete admixture, and water according to the proportion of ordinary concrete, and pour it into the mold to vibrate and compact to form a base layer.

[0052] (2), then add 5-30% of cement, 60-85% of graded glass beads, 0-5% of luminescent powder, 0-5% of toner, 0.1-6% of concrete admixture, reflective glass beads, Disperse the rubber powder, stir it evenly into a dry powder, sprinkle it on the surface of the concrete base layer in the bleeding period, and carry out calendering and compaction.

[0053] (3), after seven days of condensation, adopt the method of sandblasting and grinding to obtain the luminescent reflective concrete floor tiles made on site.

[0054] Cement, glass beads, toner, ZnS luminescent powder, reflective glass beads, concrete water reducer, concrete hardener, redispersible latex powder, and slag are all sold in the market as finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com