Radiant flux fiber filter

A fiber filter, radiation flow technology, applied in the direction of gravity filter, filtration separation, loose filter material filter, etc., can solve the problems of increased packing density and filtration resistance, insufficient protection of water quality, and unfavorable protection of water quality. , to achieve the effect of reducing cleaning cost, reducing water filtration cost and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

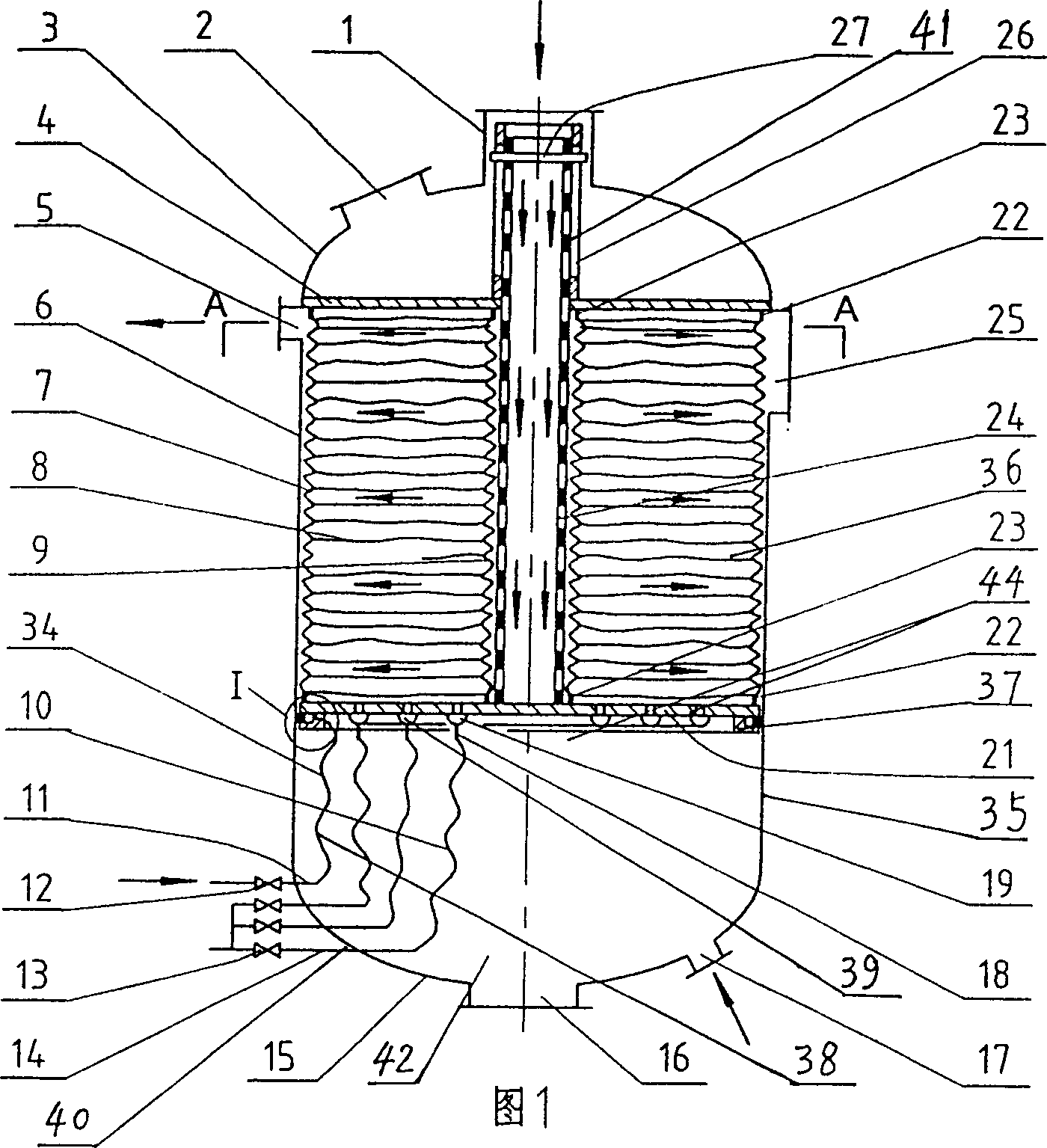

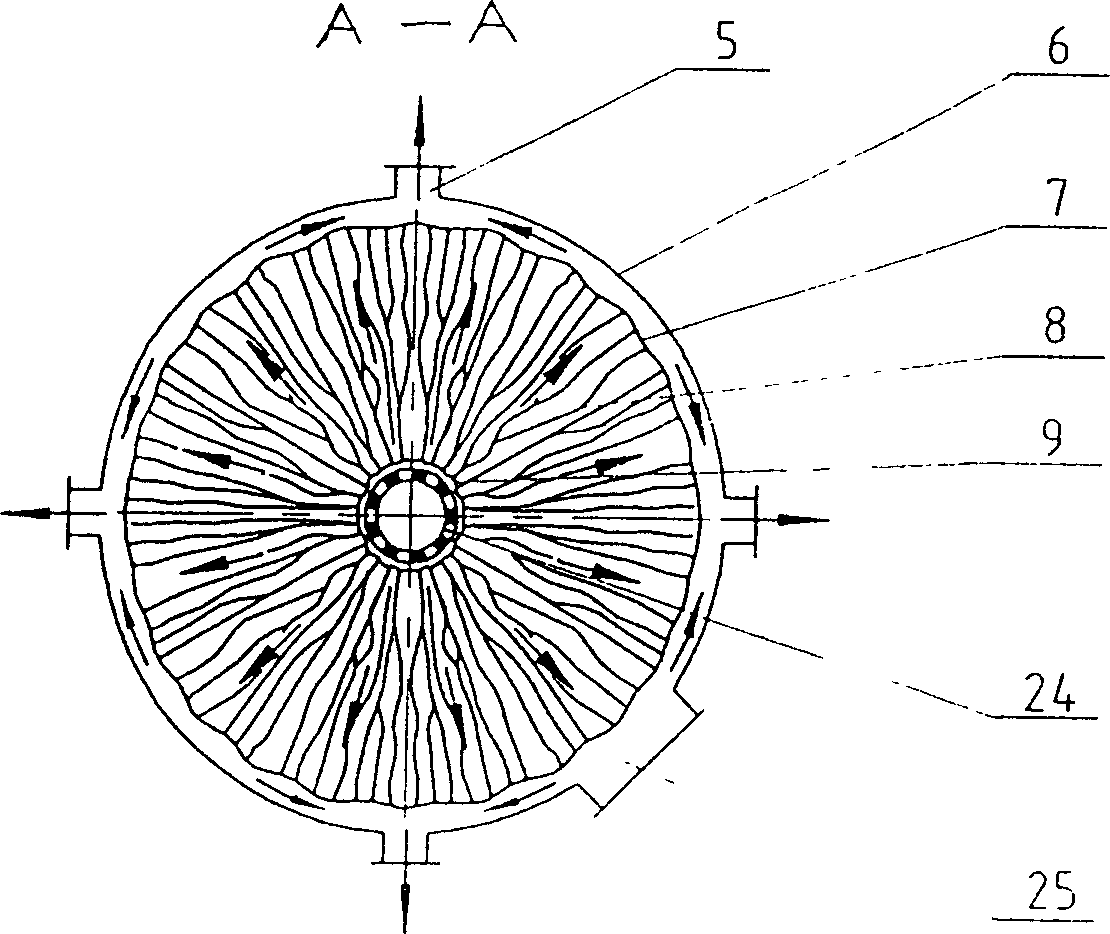

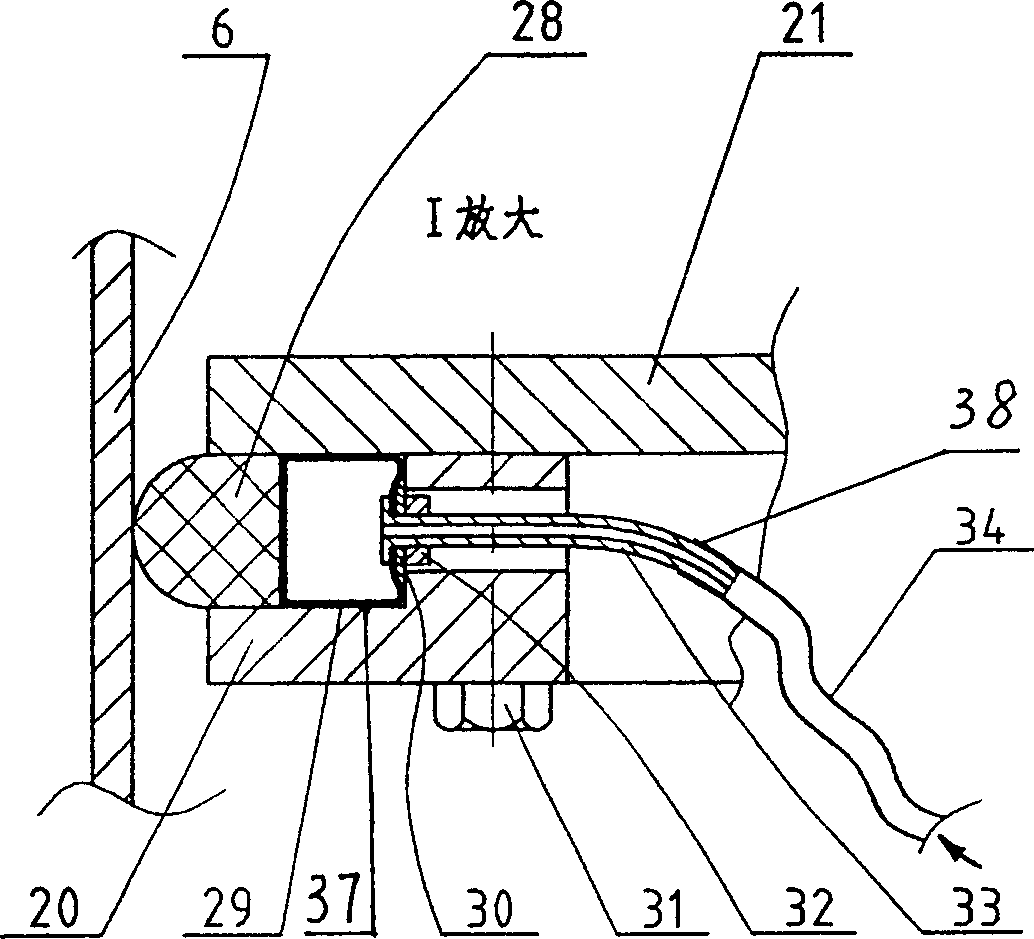

[0023] Embodiment 1: Referring to Figures 1 and 2, the container 35 of the radial flow fiber filter is composed of upper and lower heads 3, 15 and cylinder 6 welded. A water inlet 1 and a manhole 2 are provided on the upper head 3 of the container 35 , four water outlets 5 and manholes 25 are provided on the cylinder 6 , and a water inlet 17 and a manhole 16 are provided on the lower head 15 . The fixed plate 4 is welded on the upper end of the cylinder body 6 in the container 35, the upper center of the fixed plate 4 is vertically welded or connected with a guide pipe 26 with a flange, and the porous water distribution pipe 24 is welded with the floating plate 21 or connected with a flange. Installed in the guide pipe 26, and placed in the symmetrical long slot 41 provided on the guide pipe 26 through the limit pin 27 that is installed on the porous water distribution pipe 24, the water in the container 35 cannot pass through the floating plate 21 Up and down circulation.

...

Embodiment 2

[0026] Embodiment 2: Referring to FIG. 9, the internal structure of this radial flow fiber filter is the inversion of the internal structure of the radial flow fiber filter in Embodiment 1, and its structural principle is the same. It is just that in the container 35 of the radial flow fiber filter of embodiment 2, the upper floating disc 21 and the lower fixed disc 4 are installed, and the gas distribution device 39 is placed on the fixed disc 4, and the gas distribution holes and annular distribution holes provided on the floating disc 21 of the embodiment 1 are removed. The air chamber 19 and the pressure-regulating sealing device 37 can be properly compressed by the known external pressure mechanism 43 such as a hydraulic cylinder and a screw to adjust the packing density. The known external force pressurizing mechanism can also replace the water injection cavity and be connected with the lower floating plate to adjust the packing density.

[0027]Referring to Figure 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com