Jacquard machine

一种机器、提升器的技术,应用在提花机、纺织品和造纸、纺织等方向,能够解决结构复杂、提花机器功能损害、锁鼻弹性结构产生振动等问题,达到简化构造、消除振动和共振的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

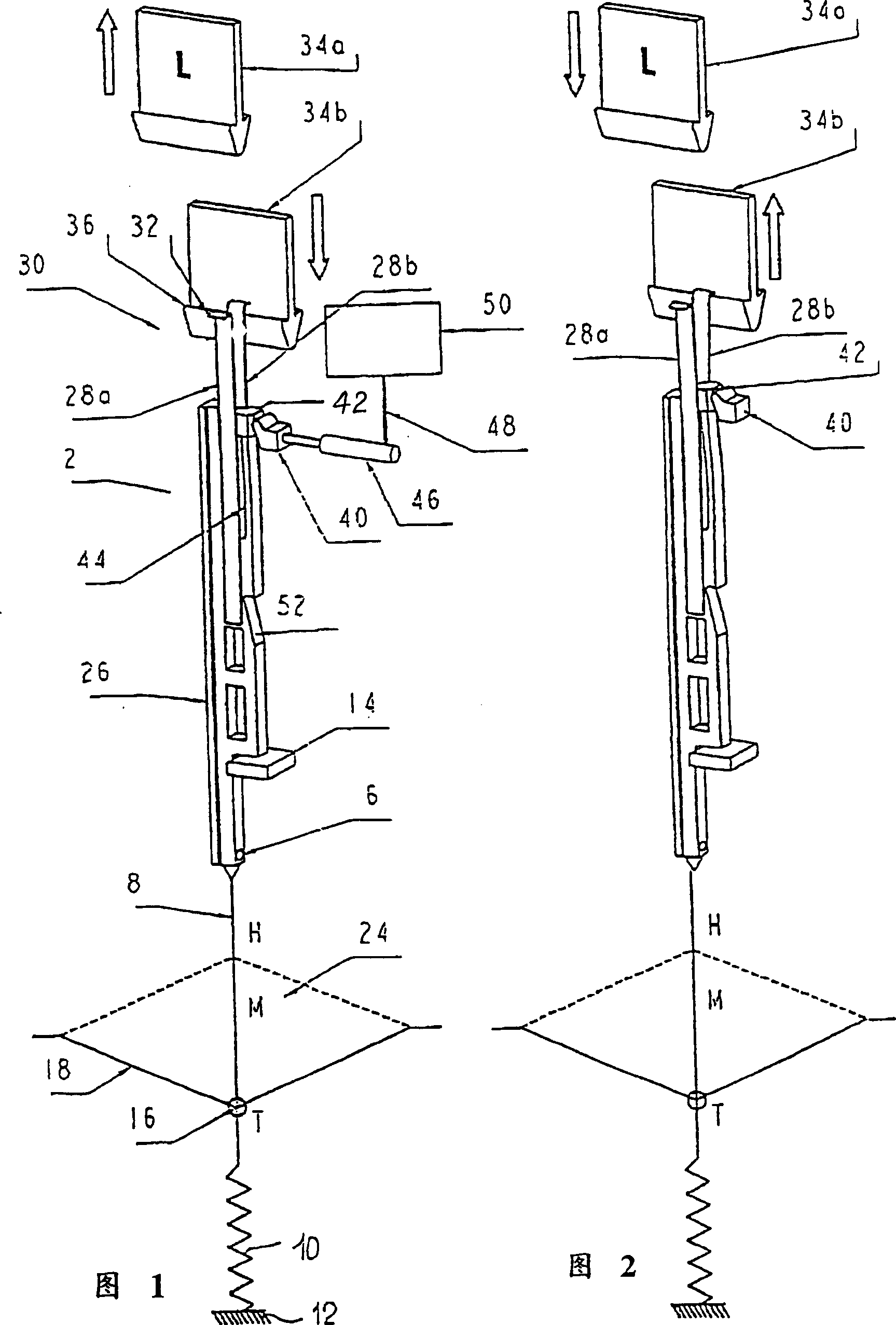

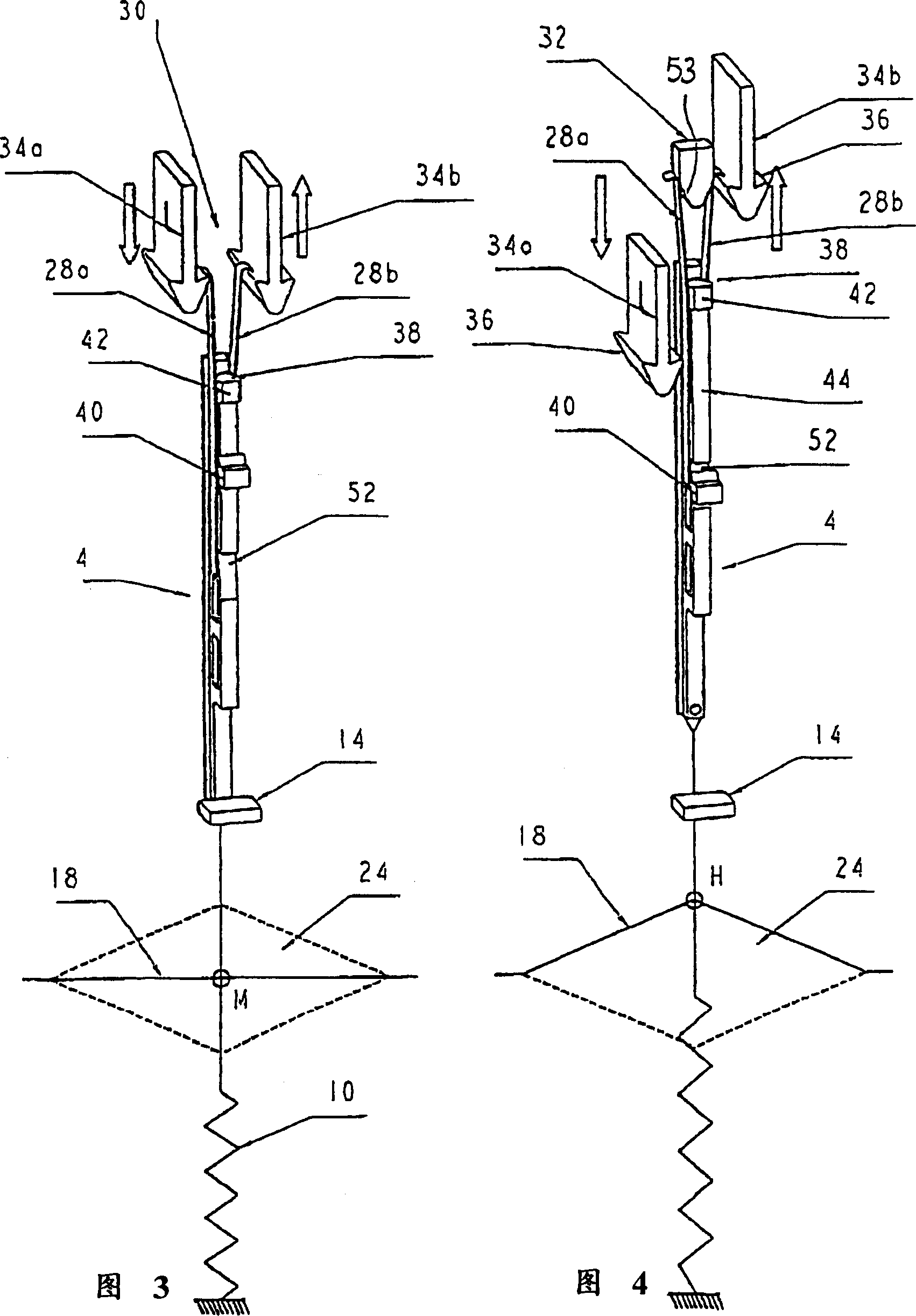

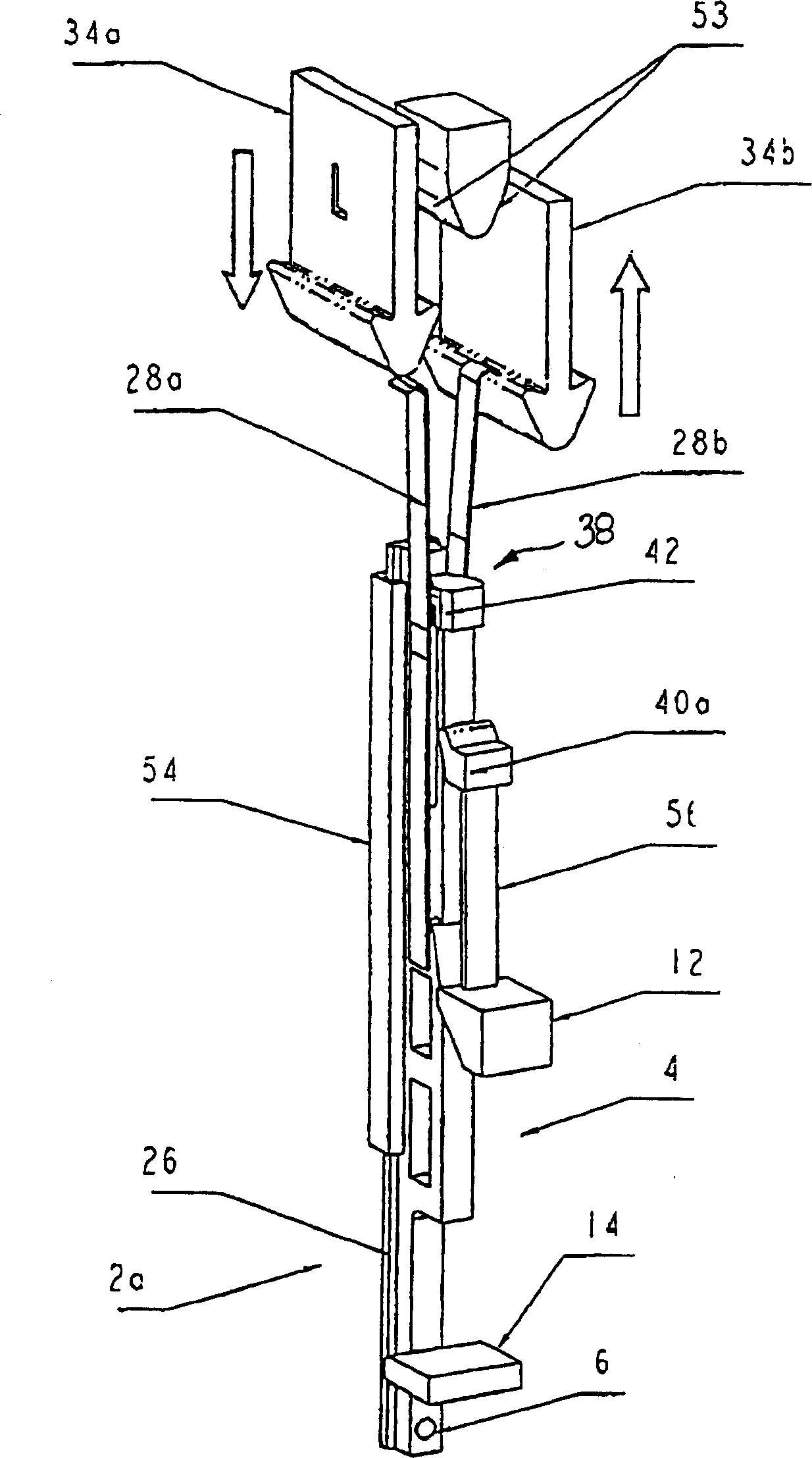

[0022] Figures 1-4 show schematic views of the lifter 2 of the Jacquard machine in different working positions, omitting parts not essential to the essence of the invention.

[0023] The lifter 2 has a mobile part 4 to which a heald 8 is connected via a ring 6 at its lower end, the heald 8 being prestressed by means of a spring 10 relative to the machine frame 12 . As a result of this prestressing, the moving part 4 is prestressed in the lower shed position T against the lower stop 14 on the machine frame. An eye 16 arranged in the heddle 8 serves to concentrate the warp thread 18 so that the warp thread 18 reciprocates out of the lower shed position T in FIG. 1 and passes through the middle shed position M in FIG. The upper shedway position H in, thus just forming a shedway 24. The mobile part 4 is held displaceably in the longitudinal direction by a shaped rear part 26 under the action of a guide of the machine frame, which is not shown here in more detail.

[0024] The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com