Ni-Zn-O based thermal sensitive ceramic and its preparing method

A ceramic material, heat-sensitive technology, applied in the field of material science, can solve the problems of complex composition, cost reduction and competitiveness, and achieve the effect of easy process, cheap raw materials, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

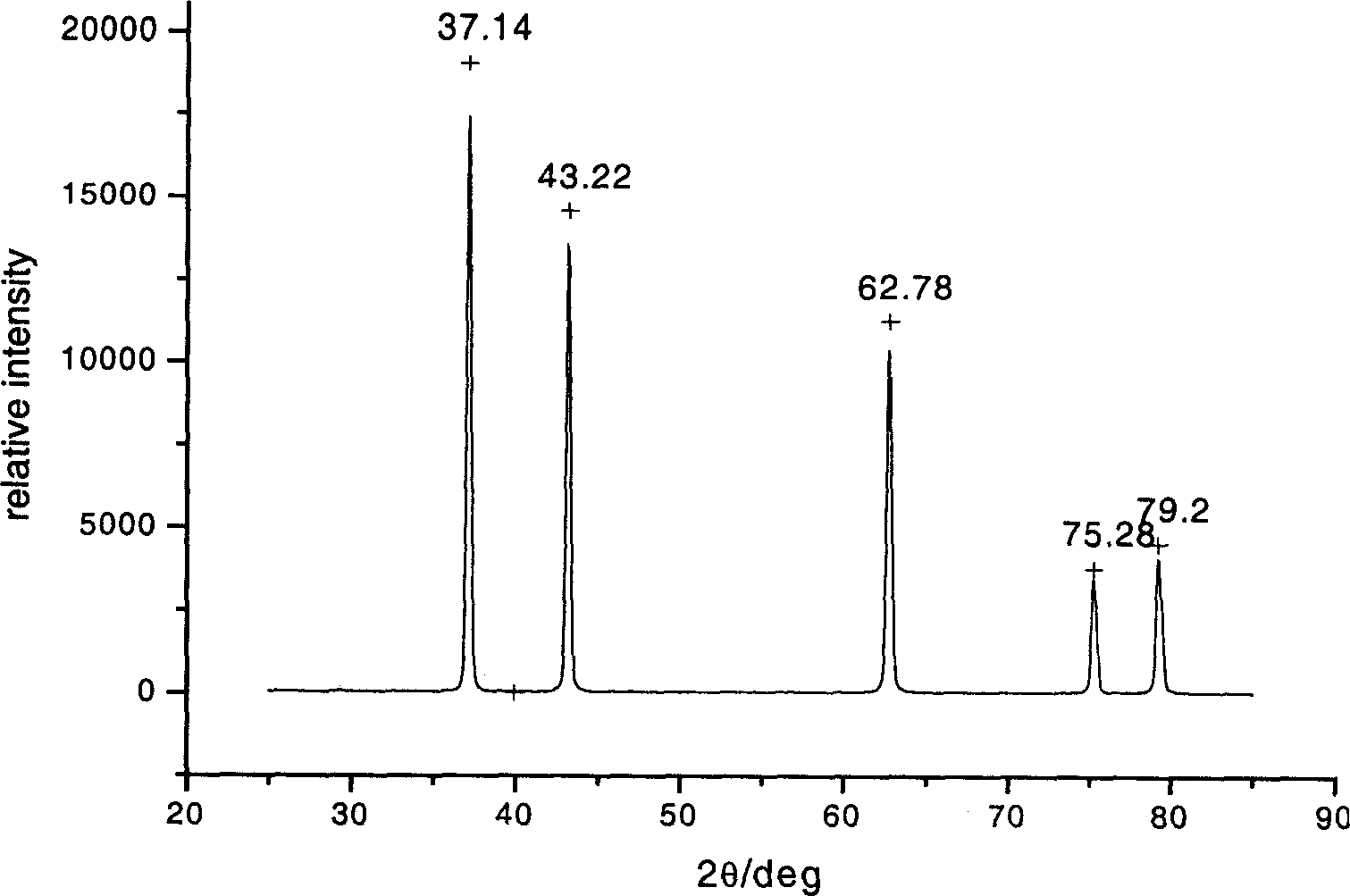

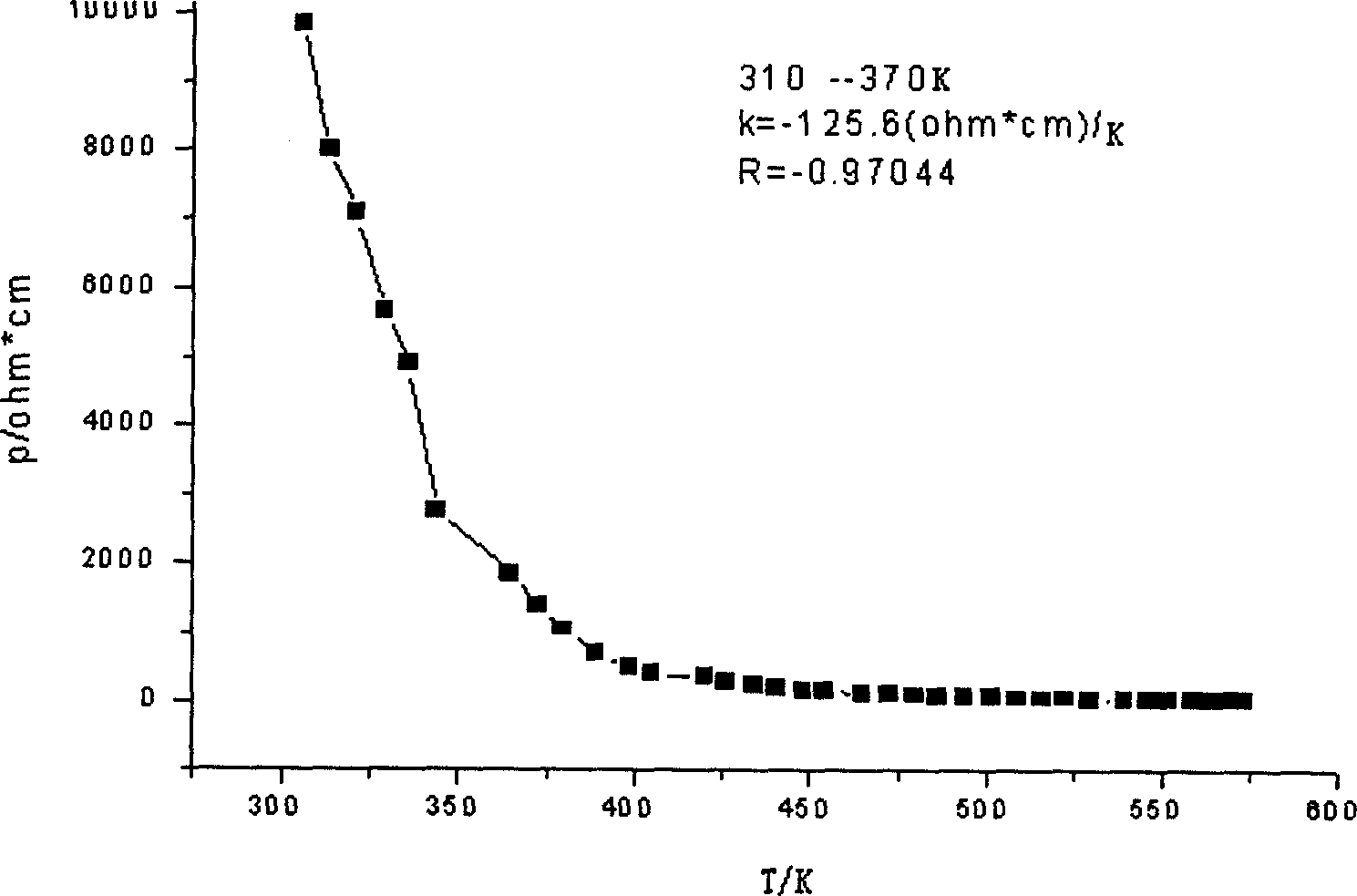

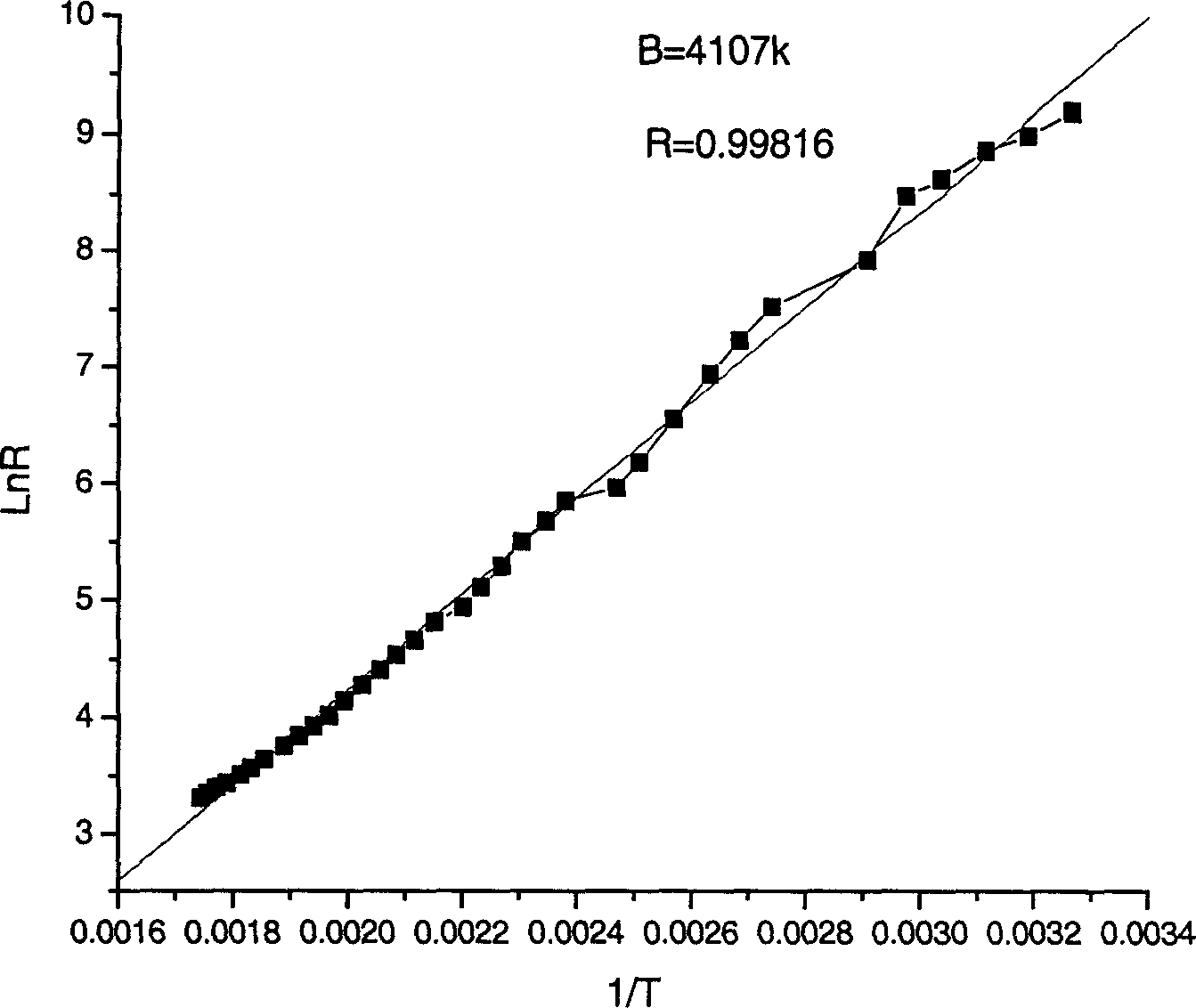

[0022] Weigh 14.621g of Ni 2 o 3 and 0.379g of ZnO, so that the molar ratio is 0.95:0.05. It was wet ball milled for 20 hours. The mixture was washed and then dried at 80°C to obtain a uniformly mixed ceramic powder. Grind and sieve the powder, add 3wt% PVA binder, dry press at about 4Mpa, and sinter in air at 1250°C for 4 hours to obtain Ni 0.95 Zn 0.05 O heat sensitive ceramic material. XRD test shows that the phase is basically Ni 0.95 Zn 0.05 O solid solution. The sintering radial shrinkage rate is 15.6%, the sintering performance is good, and the ceramics are relatively dense. Performance tests show that in the temperature range of 50-300°C, the B value is 4107K, and the linearity is 0.99816; in the temperature range of 50-100°C, the linearity of the resistance-temperature curve is 0.970, and the temperature coefficient of resistance TCR is -0.013 / K. Its corresponding data such as figure 1 , figure 2 , image 3 shown.

Embodiment 2

[0024] Weigh 14.222g of Ni 2 o 3 and 0.778g of ZnO, so that the molar ratio is 0.90:0.10. It was wet ball milled for 20 hours. The mixture was washed and then dried at 80°C to obtain a uniformly mixed ceramic powder. Grind the powder, sieve, add binder, dry press at about 4Mpa, and sinter in air at 1350°C for 2 hours to obtain Ni 0.9 Zn 0.1 O heat sensitive ceramic material. XRD test shows that the phase is basically Ni 0.9 Zn 0.1 O solid solution. The sintering radial shrinkage rate is 16.0%, the particle size after sintering is about 3 μm, and the sintering performance is good. Performance tests show that in the temperature range of 50-300°C, the B value is 4677K, and the linearity is 0.99534; in the temperature range of 50-100°C, the linearity of the resistance-temperature curve is 0.984, and the temperature coefficient of resistance TCR is -0.013 / K. Such as Figure 4 , Figure 5 , Image 6 , Figure 7 shown.

Embodiment 3

[0026] Weigh 13.357g of Ni 2 o 3 And ZnO of 1.643g, make its molar ratio be 0.80:0.20. It was wet ball milled for 20 hours. The mixture was washed and then dried at a certain temperature of 80° C. to obtain uniformly mixed ceramic powder. Grind the powder, sieve, add binder, dry press molding at about 4Mpa, and sinter in air at 1450°C for 2 hours to obtain Ni 0.8 Zn 0.2 O heat sensitive ceramic material. XRD test shows that the phase is basically Ni 0.8 Zn 0.2 O solid solution. The sintering radial shrinkage rate is 16.0%, and the sintering performance is good. Performance tests show that in the temperature range of 50-300°C, the B value is 4862K, and the linearity is 0.99643; in the temperature range of 50-100°C, the linearity of the resistance-temperature curve is 0.987, and the temperature coefficient of resistance TCR is -0.014 / K. Its related data such as Figure 8 , Figure 9 , Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com