Dust-free carloader for discharging ash from gravitational duster of blast furnace

A technology of gravity dust collector and dust collector, applied in the direction of dust collector, can solve the problems of large drop of gravity dust collector, complicated process, difficult operation and maintenance, etc., achieve reliable operation, simplify process, reduce energy consumption and operation and maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

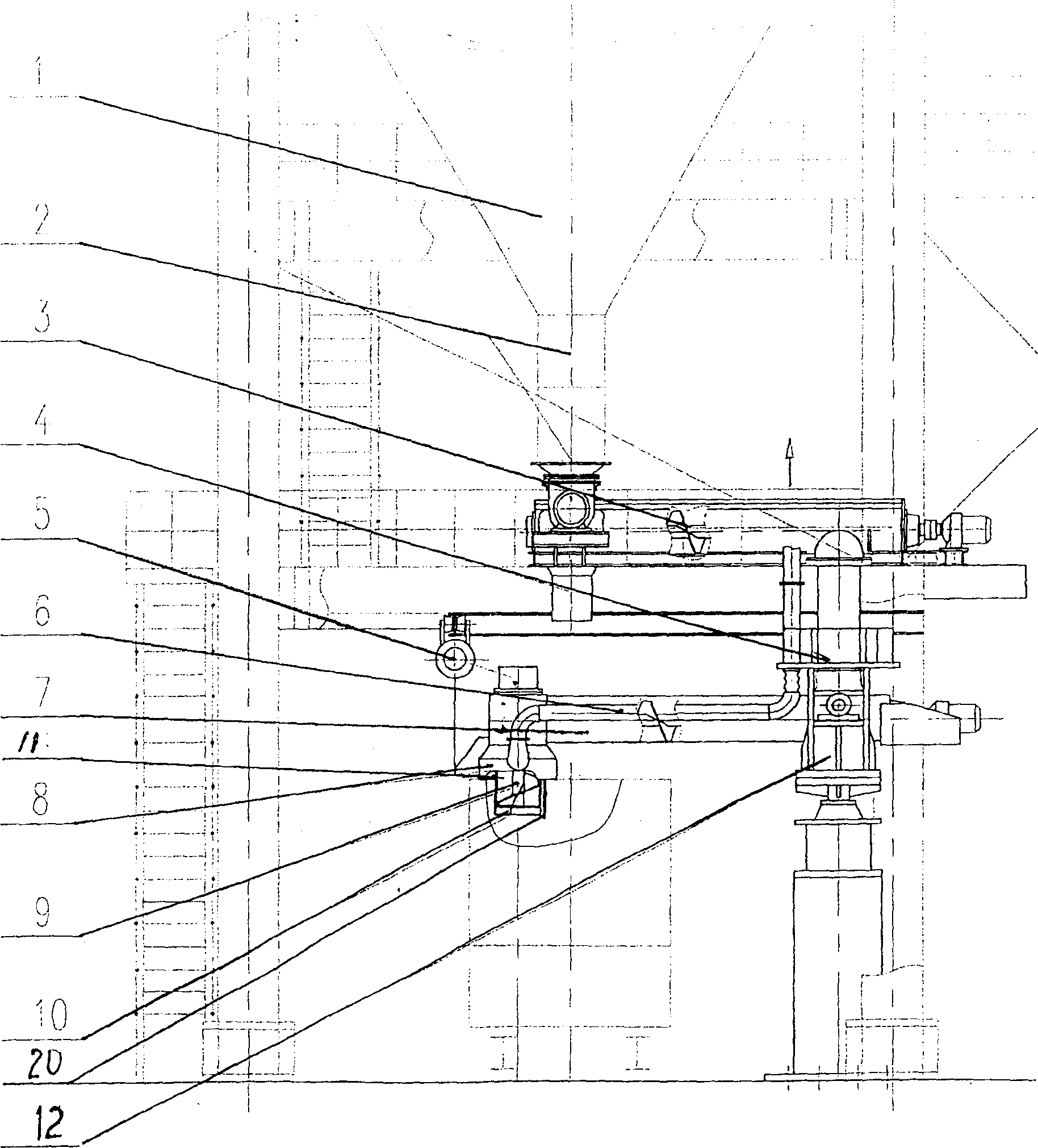

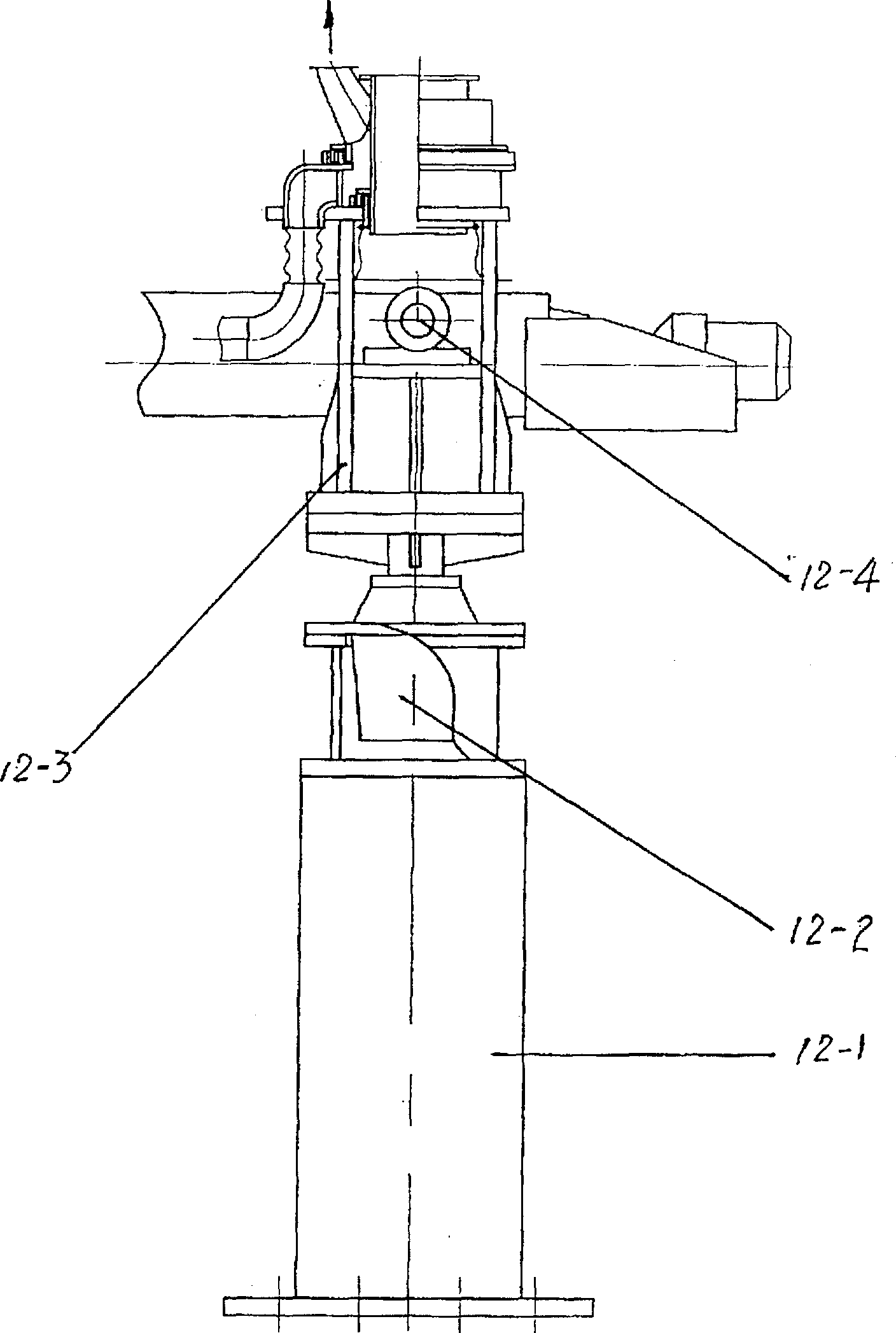

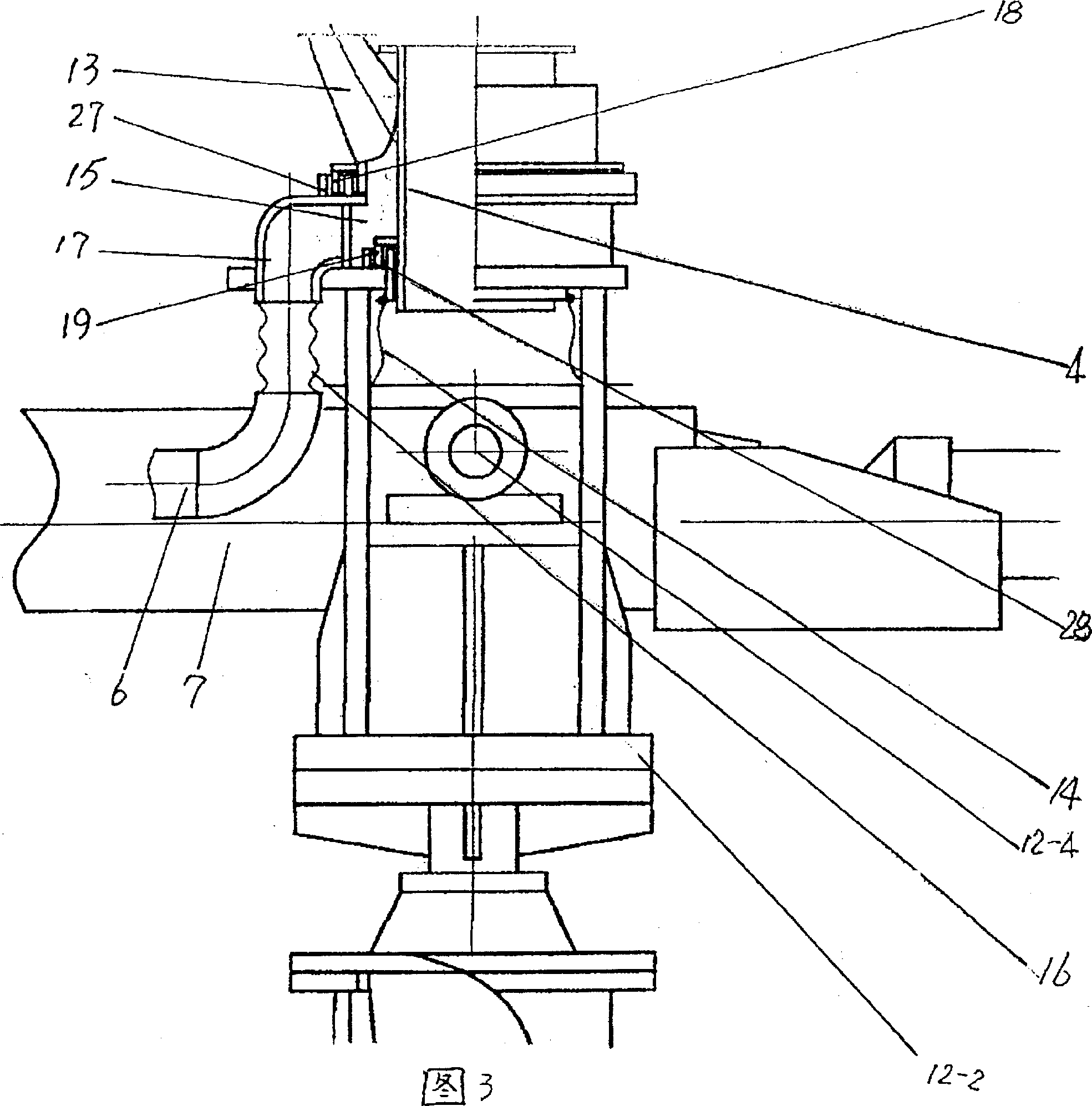

[0011] like figure 1 As shown, the dust discharge valve 2 under the dust hopper 1 of the dust collector is connected with the feeding device 3 . The feeding device includes a main feeding screw propeller 3-2, and the main feeding screw propeller 3-2 is connected with a standby ash unloading device 3-1, such as Figure 6 shown. During general ash unloading, the main feed screw propeller 3-2 rotates forward, the valve of the standby ash outlet is closed, and the standby ash unloading device 3-1 does not work; when the ash of the dust collector is wet ash or has sundries, Open the backup ash outlet valve, the main feeding screw propeller 3-2 rotates in reverse, the backup ash unloading device 3-1 works, and the wet ash is directly discharged from the backup ash unloading device 3-1. The main feeding screw propeller 3-2 communicates with the feeding device 7 capable of three-dimensional rotation through the feeding tank pipe 4 . One end of the three-dimensional rotary feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com