Desalting apparatus and process for seawater or brackish water by moistening-drying

A brackish water and seawater technology, which is applied in seawater treatment, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of difficult sealing of equipment, reduction of effective heat transfer area, difficulty in heat transfer enhancement, etc. Achieve the effect of small investment, flexible device scale and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

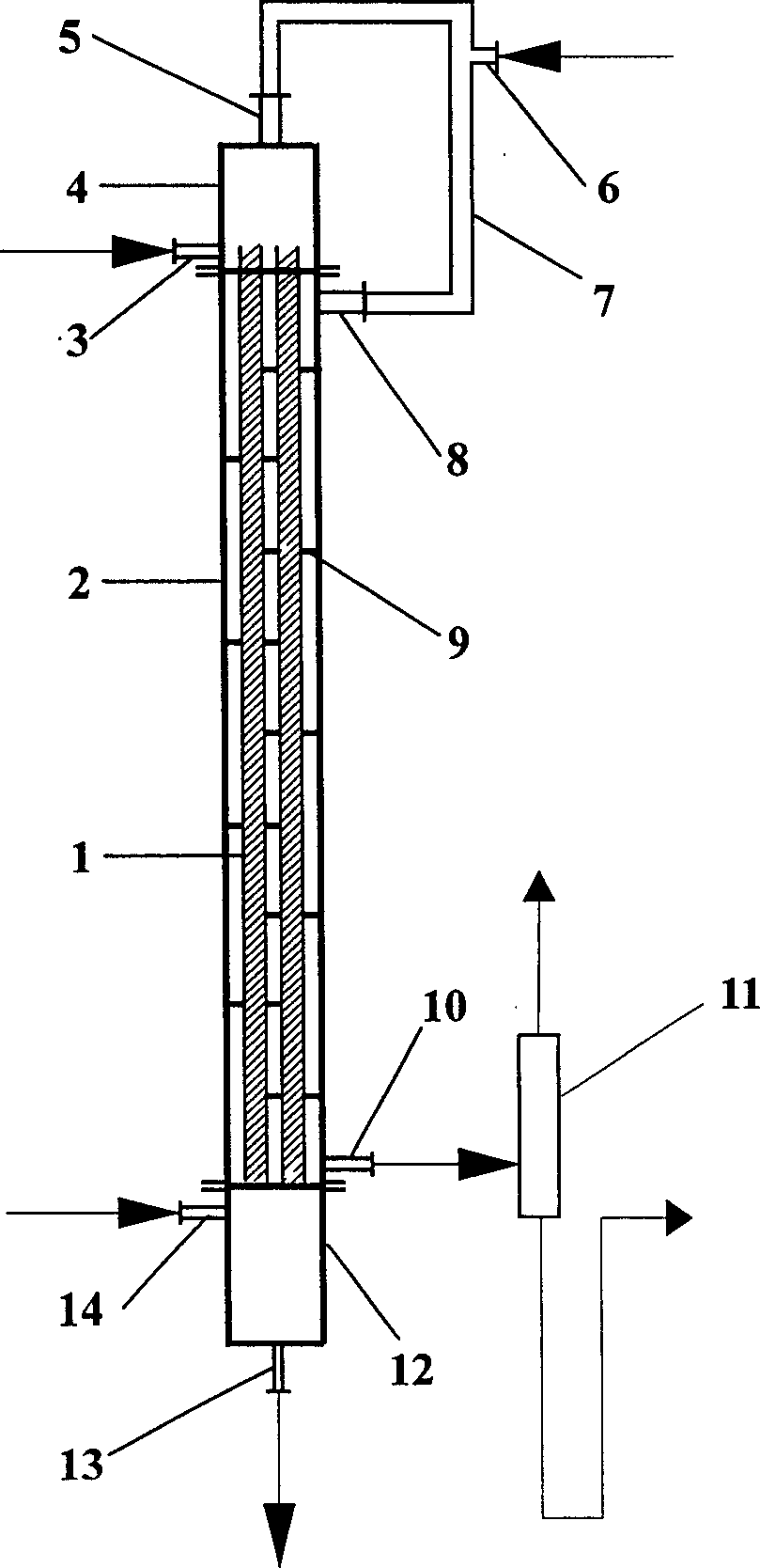

[0013] use as figure 1 The shell-and-tube desalination unit shown is operated vertically. The evaporation and humidification process is completed on the tube side of the heat exchanger, and the condensation and dehumidification process is completed on the shell side of the heat exchanger. The preheated seawater or brackish water is introduced into the upper head 4 from the hot brine inlet 3, through overflow, or through a specially designed liquid distribution device, so that the seawater or brackish water is evenly distributed into the pipe, and the water is discharged by gravity. The effect is the falling film flow along the inner wall of the tube. The temperature of the feed water is generally between 50 and 95 °C, and the flow rate varies depending on the number and diameter of the heat exchange tubes of the equipment. Usually, the falling film load is 0.0001 to 0.01 kg m -2 the s -1 between 0.0008~0.008kg m -2 the s -1 better. The carrier gas is introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com