Highly asymmetric, hydrophilic, microfiltration membranes having large pore

An asymmetric, microporous technology, applied in filtration separation, membrane, membrane technology, etc., can solve problems such as unsuitable for asymmetric membrane applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] A homogeneous casting solution was prepared using 9.3% polysulfone polymer (Udel 3500), 19% polyethylene glycol (MW200), 4.3% polyvinylpyrrolidone, 1.8% water, and 65.6% N-methylpyrrolidone. The casting solution was stored at room temperature about 25°C. The casting surface was a moving polyethylene coated paper tape with a 24 mil knife slit. After casting, the casting material was exposed to humid air (relative humidity 65-70%) for 6 seconds, and then quenched in a water bath at a temperature of 40 to 45°C.

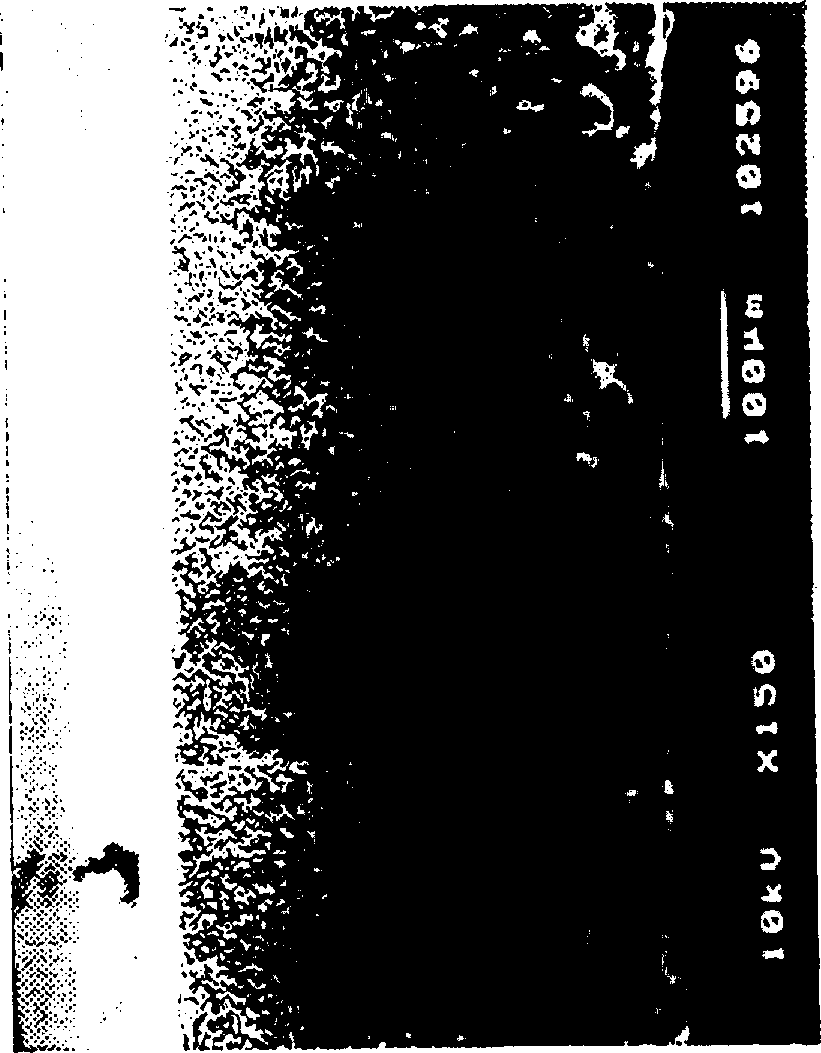

[0111] After quenching, the membrane was removed, washed with deionized water, and dried in an oven at about 100°C. Afterwards, the membranes were tested for water flow and average flow pore size. Water flow through the membrane was measured at 10 psid in a standard 47mm disc holder, and a Coulter porometer was used to measure the average flow pore size. The membrane is shown in Figure 1 and has the following properties:

[0112] Water flow (ml / min / 9....

Embodiment 2

[0114] A homogeneous casting solution was prepared using 9.3% polysulfone polymer (Udel 3500), 19% polyethylene glycol (MW200), 4.3% polyvinylpyrrolidone, 1.8% water, and 65.6% N-methylpyrrolidone. The casting solution was stored at room temperature about 25°C. The casting surface was a moving polyethylene coated paper tape with a 19 mil knife gap. After casting, the casting material was exposed to humid air (relative humidity 65-70%) for 9 seconds, and then quenched in a water bath at a temperature of 40 to 45°C.

[0115] After quenching, the membrane was removed, washed with deionized water, and dried in an oven at 100°C. Afterwards, the membranes were tested for water flow and average flow pore size. Water flow through the membrane was measured at 10 psid in a standard 47mm disc holder, and a Coulter porometer was used to measure the average flow pore size. The membrane is shown in Figure 2 and has the following properties:

[0116] Water flow (ml / min / 9.5cm 2 ...

Embodiment 3-6

[0118] Effect of Exposure Time and Humidity

[0119] The method of Example 1 was repeated, except that the exposure time and relative humidity were changed according to Table V. The effect of the changes on the prepared membranes is indicated.

[0120] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com