System for automatic tracing color codes of packing machines

An automatic tracking and packaging machine technology, applied in the direction of packaging automatic control, packaging, transportation packaging, etc., can solve the problems affecting the packaging speed of the whole machine, the system response speed is not high, the tracking accuracy is limited, etc., to achieve fast compensation speed, control method Flexible, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

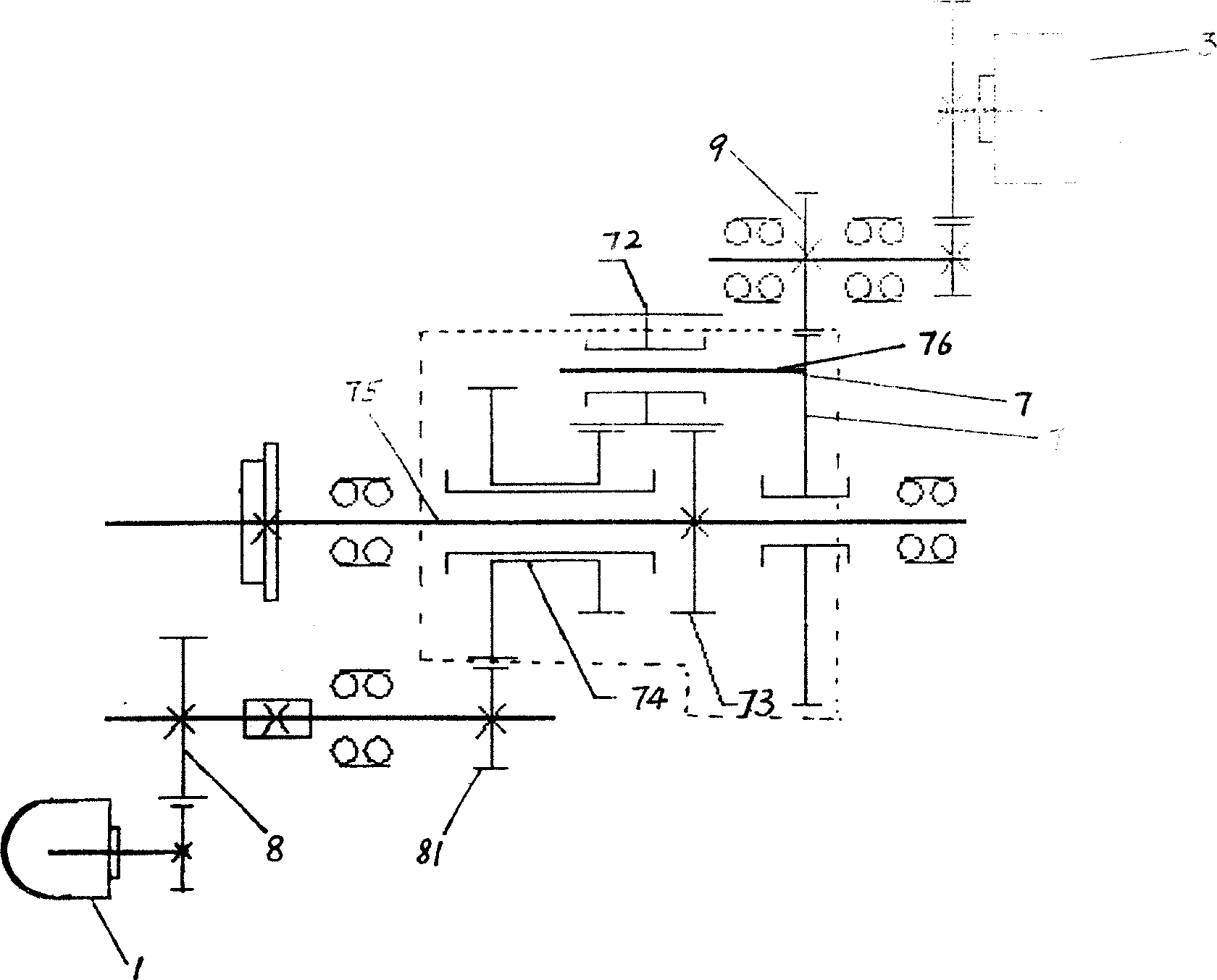

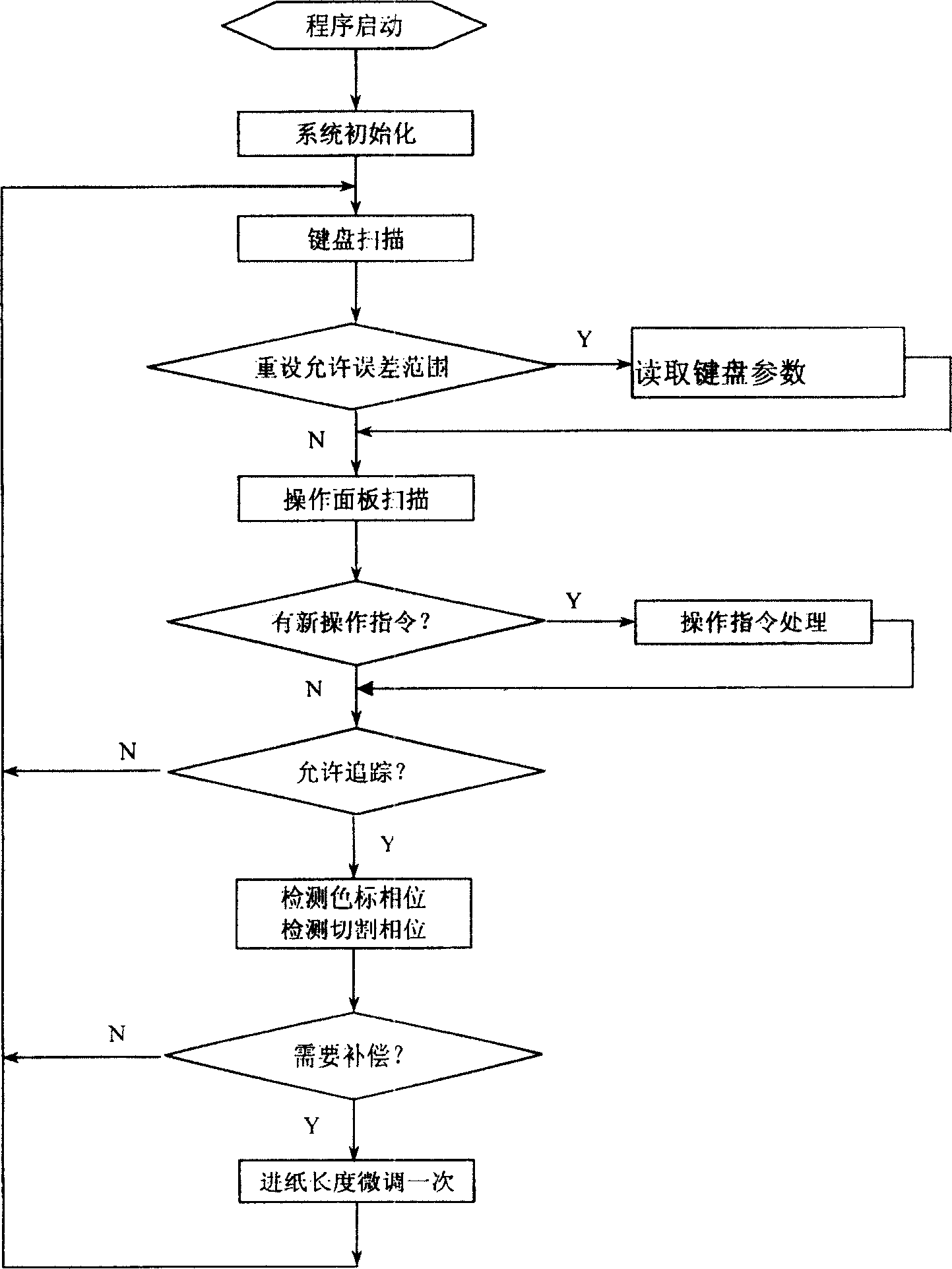

[0015] like figure 1 Shown, the present invention comprises a group of planetary gear 7, and described planetary gear 7 comprises sun gear 74, sun gear 73, planetary gear 72 and rotating arm 76, and input gear 81 meshes with sun gear 74, to input power, sun gear 74 and rotating arm 76 are sleeved on the power output shaft 75, and the sun gear 73 is fixedly connected with the power output shaft 75, and the sun gear 74 and the sun gear 73 are meshed with the planetary gear 72 simultaneously. A pivoting arm gear 71 is fixedly connected to the pivoting arm 76 , and the pivoting arm gear 71 meshes with the gear pair 9 . The main motor 1 is connected to the sun gear 74 through the hanging wheel 8, and the paper feeding length can be set according to the wrapping paper specification by changing different hanging wheels. Under the action of the stepping motor 3 holding torque, the rotating arm 76 remains locked, and the planetary wheel 72 is actually a passing wheel. When the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com