Electromagnetic induction device

An electromagnetic induction and coil technology, applied in the transformer/inductor shell, preventing/reducing unnecessary electric/magnetic influence, transformer/reactor installation/support/suspension, etc., can solve the problem of large size and long-term insulation Deterioration, local surface pressure increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Implementation form 1:

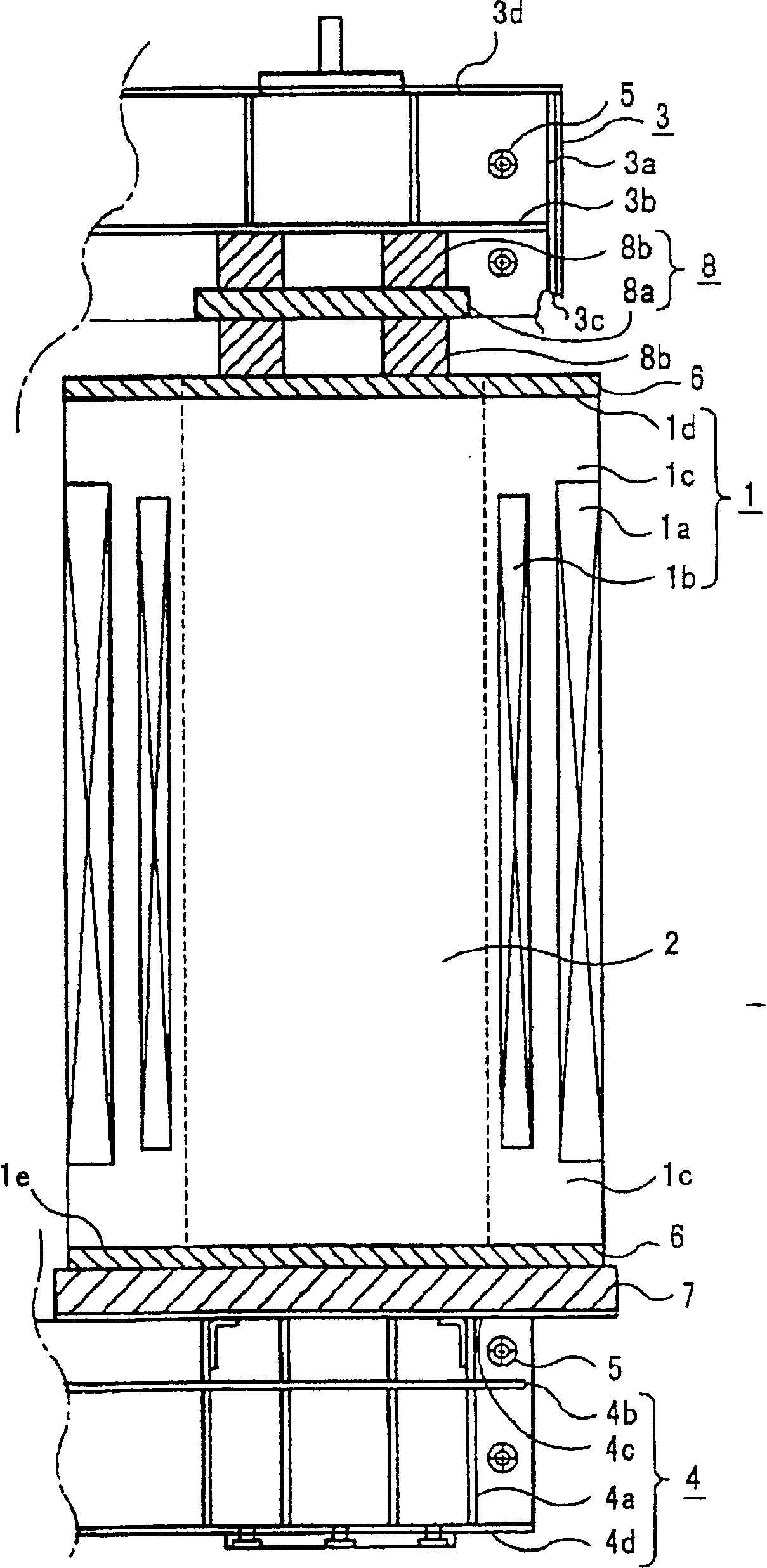

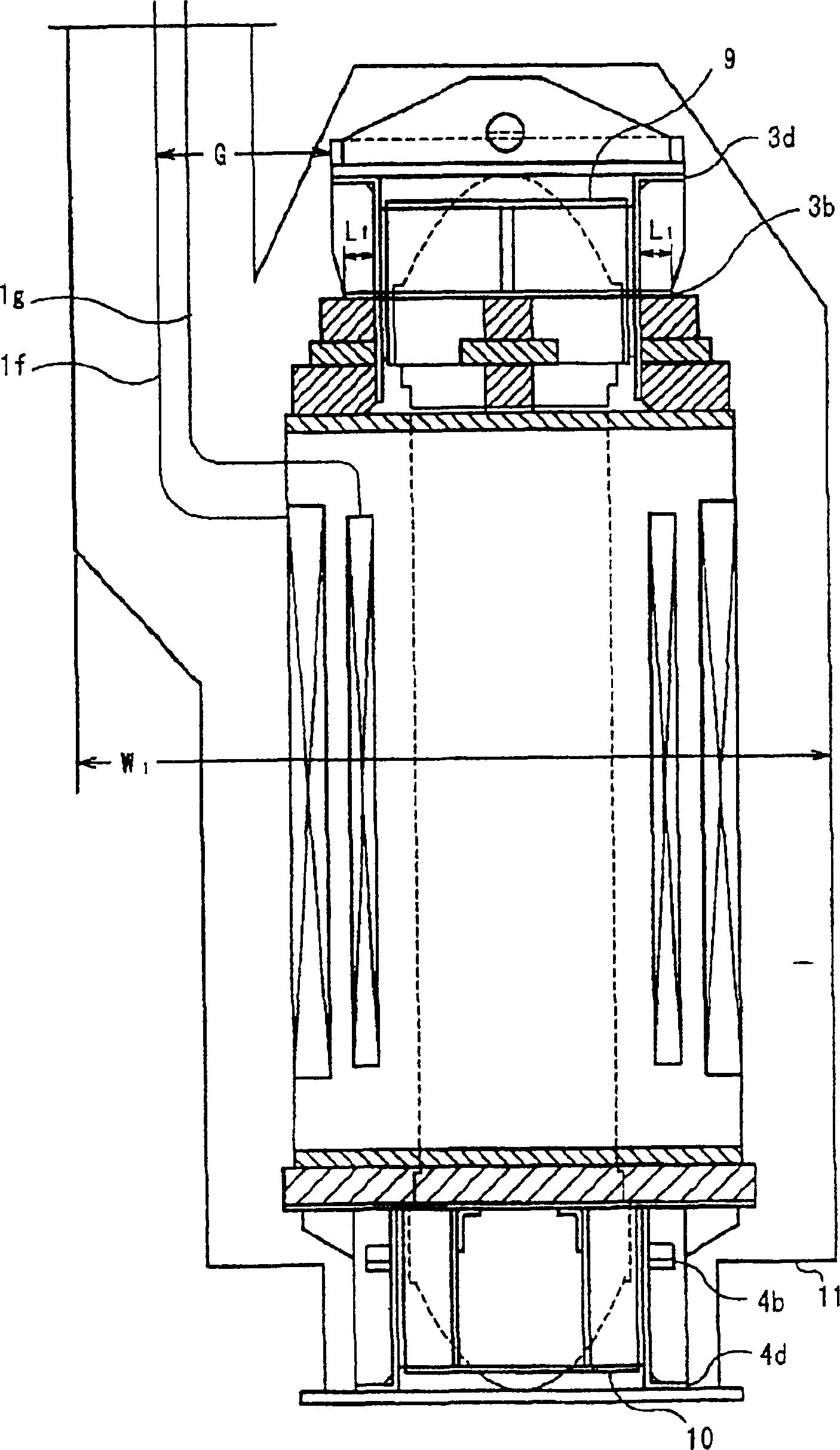

[0017] based on the following figure 1 , figure 2 Embodiment 1 of the present invention will be described. figure 1 It is a front view of the transformer, and only one of the three phases is shown. figure 2 for figure 1 side view.

[0018] In the figure, 1 is a coil, 1a is a high-voltage coil, 1b is a low-voltage coil, and 1c is an insulating block. These 1a, 1b, and 1c usually form an integrated coil 1. 1d is the upper end surface of the coil, and 1e is the lower end surface of the coil.

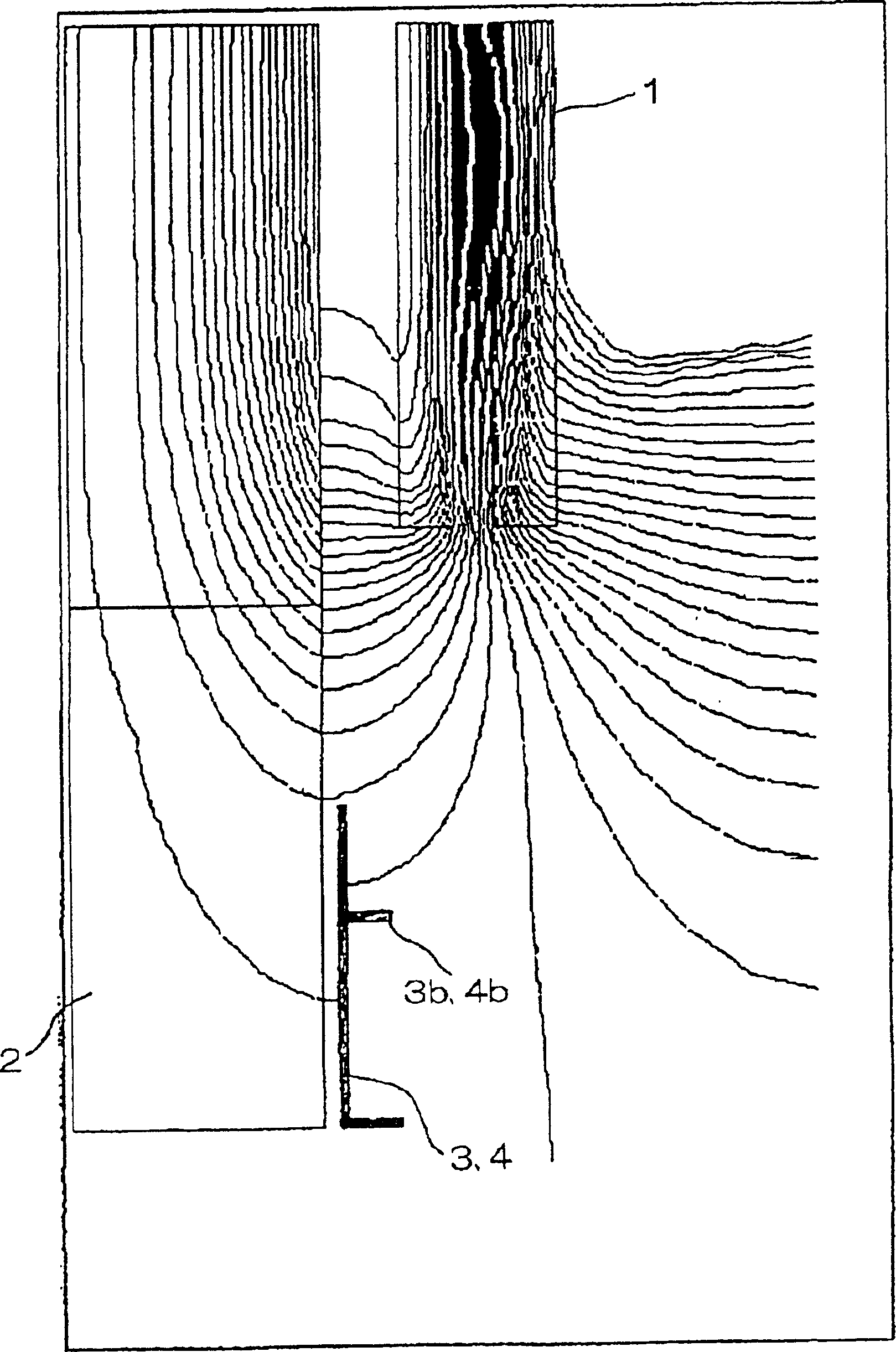

[0019] 2 is an iron core, 3 and 4 are upper and lower end frames, respectively, and the vertical members 3a and 4a and the horizontal members 3b, 3d, 4b and 4d are made of reinforcing materials, etc., which are not shown in the illustration. Moreover, the upper and lower end frames have end frame end faces 3c, 4c, and the above-mentioned horizontal parts 3b, 4b are set separately from the end frame end faces 3c, 4c. In addition, if figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com