Stepped engine frame

An engine, step-shaped technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problem of increasing the number of parts and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be described in detail with reference to the accompanying drawings.

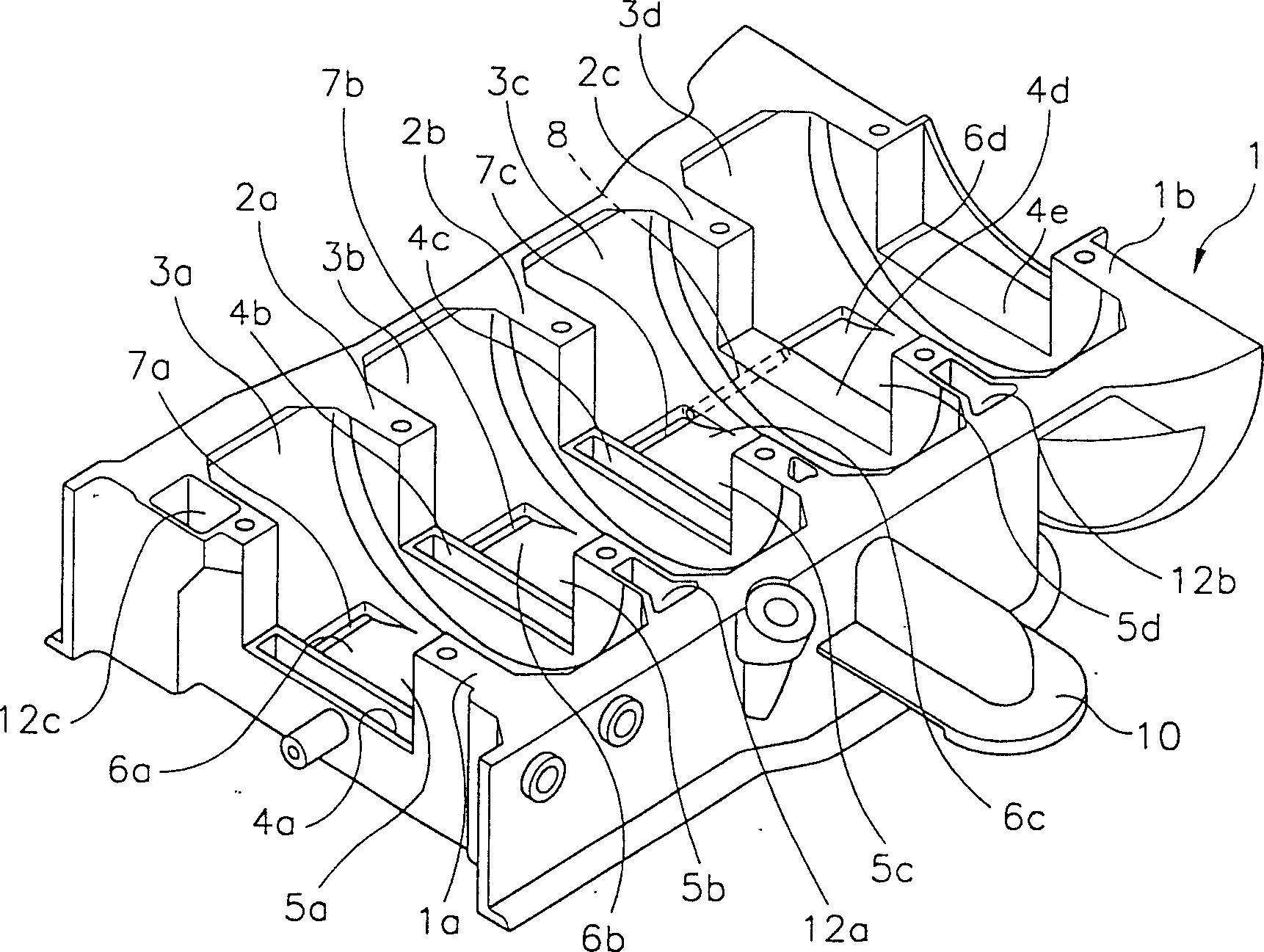

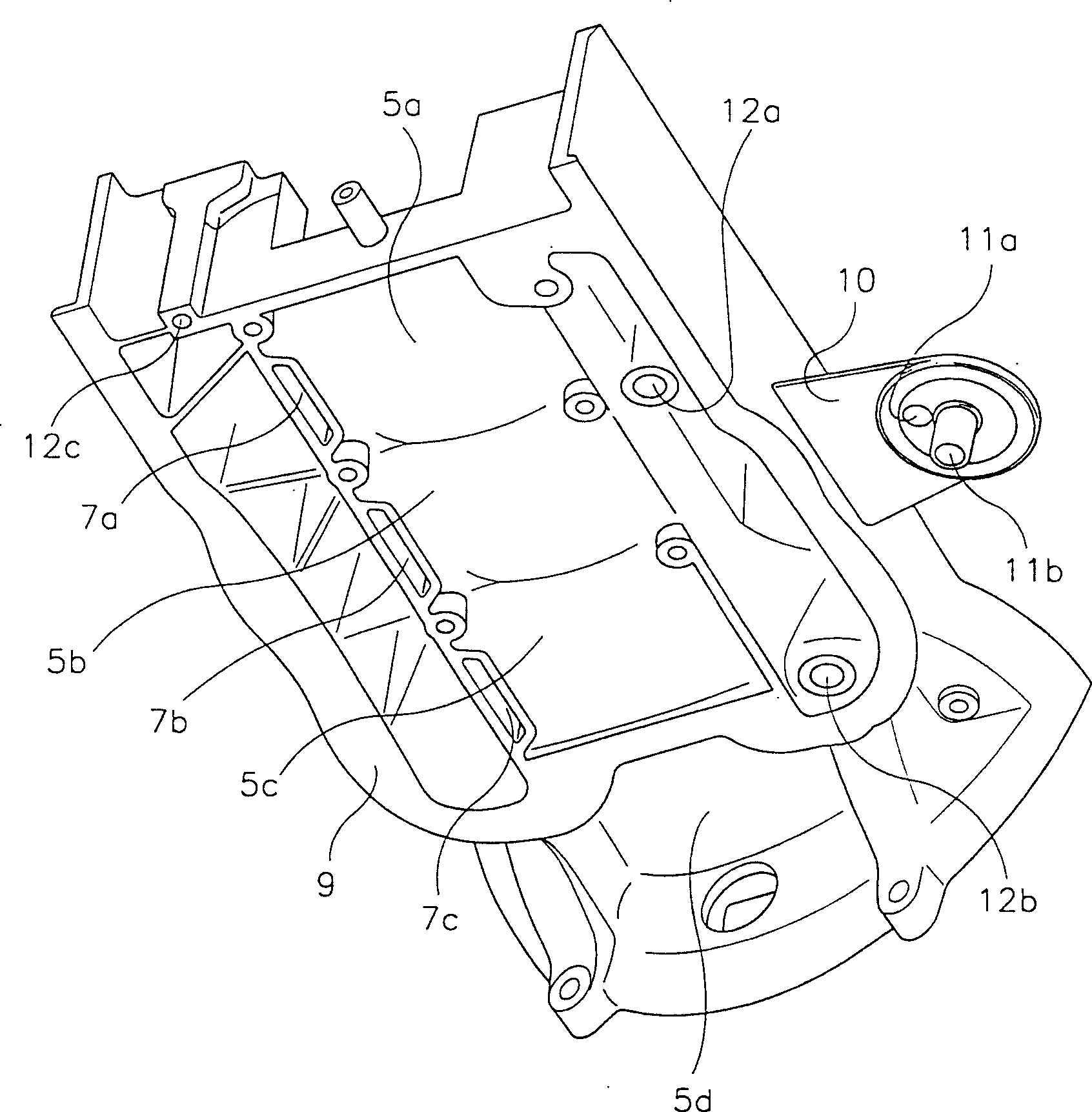

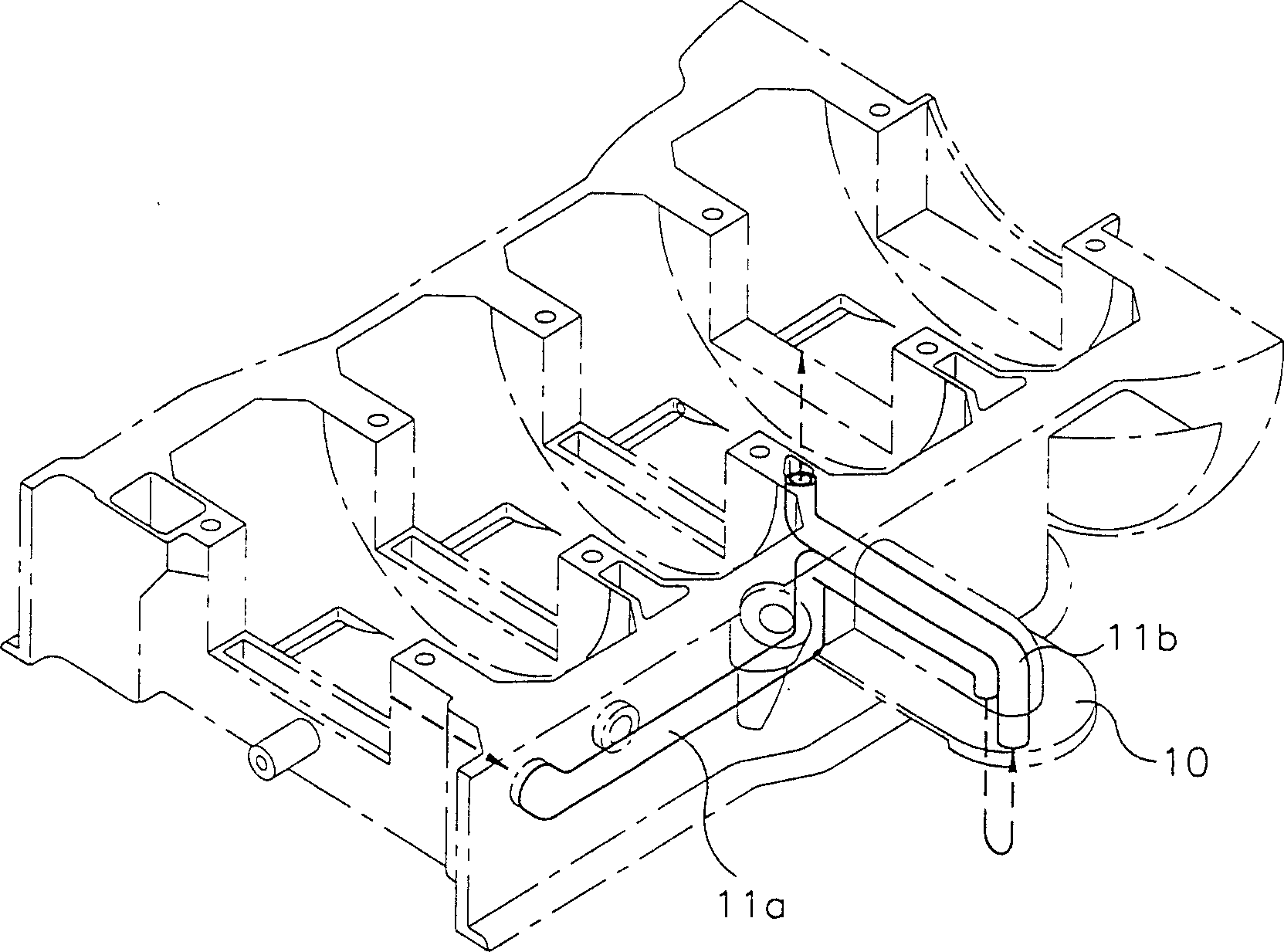

[0019] As shown in the figure, the stepped rack is constructed as follows. That is, a substantially elongated rectangular outer cylinder block 1 is formed in the casing of the four-cylinder engine. Inside the rectangular outer cylinder block 1, three partition walls 2a, 2b, and 2c are formed at equal distances, thereby forming four crankcases 3a, 3b, 3c, and 3d.

[0020] On the partition walls 2a, 2b and 2c and the front wall 1a and the rear wall 1b of the outer cylinder block 1, several elongated upward openings are formed, namely the main bearing installation parts 4a, 4b, 4c and 4e, which are used to install the main bearings to support crankshaft. Wherein, the outer end of the main bearing mounting portion 4e of the outer wall 1b is a part for connecting with the transmission input shaft, which is arcuate or almost arcuate, so that noise and vibration can be suppre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com